- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision pneumatics

Results for

Precision pneumatics - Import export

KENDRION KUHNKE AUTOMATION GMBH

Germany

Pneumatic timers are used for the precise time control of pneumatic signals in pneumatic circuits or systems. The pressure-independent function of time delay starts when pressure is applied to the control port. After the pre-selected time is elapsed, an internal 3/2 way valve is switched. The pneumatic timer is reset to the initial condition if the control port is vented for at least 300 ms. The adjustable time delay depends on the chosen version and amounts between 0.5 and 180 s. Due to its design the control pressure level must not be below working pressure level. As a result of the fire-risk evaluation according to EN 13463-1, the pneumatic timers are not subject to ATEX regulations. This means they may also be used in explosion hazardous areas as defined in IIG/ IID.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Pneumatic timers are used for the precise time control of pneumatic signals in pneumatic circuits or systems. The pressure-independent function of time delay starts when pressure is applied to the control port. After the pre-selected time is elapsed, an internal 3/2 way valve is switched. The pneumatic timer is reset to the initial condition if the control port is vented for at least 300 ms. The adjustable time delay depends on the chosen version and amounts between 0.5 and 180 s. Due to its design the control pressure level must not be below working pressure level. As a result of the fire-risk evaluation according to EN 13463-1, the pneumatic timers are not subject to ATEX regulations. This means they may also be used in explosion hazardous areas as defined in IIG/ IID.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Spray and spit nozzles Variety, precision, flexibility: the right solution for every spray task Uniform precision No matter if thin films are to be applied evenly or the smallest lubrication points need to be met with precision – we have the right spray nozzle for you. We have the right solution for all of your application tasks: from a spare part through to an individual standalone configuration to meet your requirements. Features & benefits • Infinitely variable, precise control (spray interval, pressure) • Pneumatic or electric control • Low mist nozzle caps for flat or round spraying • Self-cleaning Design versions and details Spray nozzle SD 16: precision application of fluid media The SD 16 ensures you are able to apply the thinnest films of media such as low-viscosity oils and release agents with precision. For example, the pneumatically controlled, compact nozzle can be integrated directly in a forming tool to facilitate targeted, practically mist-free wetting. Depending o

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Spray nozzle SD 16: precision application of fluid media The SD 16 ensures you are able to apply the thinnest films of media such as low-viscosity oils and release agents with precision. For example, the pneumatically controlled, compact nozzle can be integrated directly in a forming tool to facilitate targeted, practically mist-free wetting. Depending on the nozzle cap used it is possible to generate a flat or round spray.

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT pressure relief valves for our high pressure pumps ensure optimum working pressure at all times. They can be configured to control pressure either by mechanical pre-adjustment or by remote pneumatic control. We are also able to manufacture many of our pressure relief valves in special materials, making them ideal for the process industry. In addition, our control rods are made from ceramic or stellite, making all our valves highly wear resistant.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

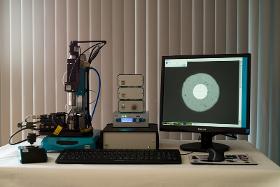

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

stable iron cast stand with coarse dovetail drive and motorized autofocus axis video system with high resolution camera, integrated incident illumination X/Y stage and downholder pneumatic ultra high-precision jaw chuck self developed imaging software with customer specific application program

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Fully automatic labeller \ Label printing and dispensing system for labelling bags Basic concept of the label printing dispenser: Bag labelling with variable data: The EDS620i-VCB label printing and dispensing system was developed for labelling sacks. The label is applied to the bag via a pneumatic label transfer unit. To achieve a precise application result, a pneumatic pressure roller is used. The sack label is then recorded fully automatically via a barcode scanning station and reported to the b+b Siterserver. The basis of the pressure dispensing system is the EDS 620i label pressure dispenser. This is designed for industrial operation and enables you to label your products and their packaging precisely, reliably and quickly using different applicators and label transfer modules.

Request for a quote

FILLTECH GMBH

Germany

The profiFill 4.0 is a highly flexible filling solution for CO 2/N 2O or mixed gasses. Through a pre-programmed filling process, which can be easily configured, adjustable individual solutions and consistent documentation can be ensured. The ProfiFill station is a universal filling station. No matter what cylinder your market requires, our equipment can be adapted to your needs. A clamping unit ensures safe and ergonomic filling. Highlights Ergonomic, durable, fast Lifting unit for short cylinders Pneumatic valve open/close unit Maintenance-free DryLin T-Linear guiding 4 load cells for precision and easy calibration Pneumatic filling head Legal for trade Technical Data: Weighing range: 0-150kg / 0-330lbs. Filling range: 6-50 kg / 0-330 lbs. Cylinders: up to 300 x 1800 mm / 11.8 x 70.8 in. Dimensions: 910 x 800 x 2300 mm / 35.8 x 31.5 x 90.5 in. Weight: approx. 300 kg /661 lbs. Weight Scales & Controls 999 storable cylinder types (PLU) Automatic filling process; automatic closin

Request for a quote

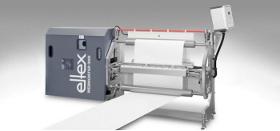

ELTEX-ELEKTROSTATIK-GMBH

Germany

In the past, Eltex Remoistening systems have guaranteed high quality printed products mainly on fastrunning and wide machines. The WEBMOISTER 3000 ensures high-quality products in all heatset web offset machines. Using a new nozzle concept, both lighter and heavier grammages can be remoistened at all web speeds with ultimate precision and homogeneity. The new pneumatic atomizing nozzles are capable of applying smallest water quantities without developing waste water. The modular structure of the nozzle bar allows the WEBMOISTER 3000 to remoisten paper webs in widths of as much as 3 meters. In heatset web offset printing, paper loses moisture during drying. The WEBMOISTER 3000 remoistening system increases the water content in the paper after drying, returning to the level required and thus guarantees high quality in all heatset web offset products.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The Peter Wolters AC 2000 double-sided batch processing machine is designed for high-precision series production of workpieces. Thanks to its modular design, the AC 2000 can be used as a fine grinding, lapping, honing and polishing machine. Like all machines in the microLine© series, the AC 2000 relies on proven core components such as the high-precision pneumatic loading system, the non-contact micro-measurement control, the powerful drive technology and the PC-supported machine guidance. The software used for this is specially developed by Peter Wolters and enables complete menu-driven and intuitive operation of the machine. For optimum access to the working area, the entire upper part of the machine can be swung out.

Request for a quoteResults for

Precision pneumatics - Import exportNumber of results

11 ProductsCountries

Company type