- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pre-press

Results for

Pre-press - Import export

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 2009 CTP system for thermal plates autoloader developer Glunz + Jensen plate stacker PST 26 incl. RIP / Software / workstation operating hours 2.500 2015 new server by Heidelberg Delivery time: immediately Ref: HE190336A Please ask for price. We ship and install worldwide!

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 2007 CTP system for thermal plates chemistry free autoloader resolution 2.400 dpi Prinect Signa Station plate stacker PST 26 Prinect Shooter Workstation Prinect MetaDimension Prep Delivery time: immediately Ref: HE230243A Please ask for price. We ship and install worldwide!

Request for a quote

FORBO SIEGLING GMBH

Germany

With Siegling Transilon, the gap is often bridged between the classical conveying function from “A” to “B” and an active function in the production process. For example, in the textile industry our processing belts stack thin layers of web, in large bakeries they form balls of dough, in the wood industry they compress chip mat in the pre-press, in dairies milk is coagulated on the belts to form cheese. Here are just a few examples of process operations. Cross-lapping of web layers in the nonwoven industry. High production speed and acceleration of masses while the web is guided directly between the belts places extremely high demands on the processing belts.

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Strapping or banding of 3- and 4-point cartons User-friendly and intuitive Format change in less than 2 minutes Change between strapping and banderole in approx. 7 minutes Always the right band for the product - Zero defect 5000 bundle recipes ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 12 mm / 28mm, either Strap end detection system with automatic discharge of remaining strap DAT 'Direct-Access-Technology' EPP 'Exact Product Path' GreenTech energy concept, low power consumption OPTIONAL: Machine movable OPTIONAL:Bundle stop plate for second strap OPTIONAL: Bundle compensator backside OPTIONAL: Narrow products, min. package width 95 mm OPTIONAL: Fully automatic format adjustment, format change in 30 seconds Bundle stop plate with pre-positioning, no contact with bundle when clearing the bundle, with quick adjustment Bundle press, pre-positioning and electric driven Production data analysis via Ethernet/USB SMART TOUCH – Icon control concept Wear-free,...

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Universal strapping of 3 and 4-point folding boxes User-friendly and intuitive Format change in less than 2 minutes Robust and extremely low maintenance ETS - pull-out strapping module High capacity 5000 bundle recipes ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap end detection system with automatic discharge of remaining strap DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam EPP 'Exact Product Path' GreenTech energy concept, low power consumption OPTIONAL: Machine movable OPTIONAL:Bundle stop plate for second strap OPTIONAL: Bundle compensator backside OPTIONAL: Narrow products, min. package width 95 mm OPTIONAL: Lateral belts with quick adjustment OPTIONAL: Fully automatic format adjustment, format change in 30 seconds Bundle stop plate with pre-positioning, no contact with bundle when clearing the bundle, with quick adjustment Bundle press, pre-positioning and electric driven Production data analysis via Ethernet/USB SMART TOUCH –...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

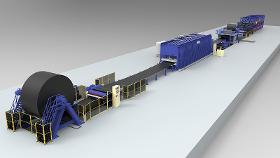

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

One of Siempelkamp’s core competences is the design and manufacture of presses for the rubber industry. With our expertise in this eld we are the world’s number one in steel-cord and conveyor-belt presses with many of the conveyor belts used around the world being manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straightrunning stability. Siempelkamp's excellent manufacturing and high-quality plants are eld proven. Services Single-source supplier Uniform pre-tensioning of the individual steel cables Best pressure distribution in our vulcanising presses Cable clamping and tensioning device with a heavy clamp Compactor lorry with pre-press Pull-roll stand Reeling elements Advantages Excellent thickness tolerances due to multi-cylinder press without requiring press bolsters Safe vulcanizing process for various belt widths by controllable pressure distribution Transparent and controllable production process

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

Description In digital high speed printing, paper loses moisture during drying. The moisture loss leads to considerable quality and efficiency issues. Electrostatic remoistening increases the water content in the paper after drying, returning to the level required and thus improves quality and productivity throughout the entire process chain. The contactless remoistening system DIGIMOISTER 1500 can be installed in any new or existing digital high speed press. The pre-charging and the two-substance nozzle technology are patent protected. Advantages: Precise remoistening results at highest production speeds Flat books or signatures Less electrostatic charges on the paper Dimensional stability (no expansion) No broken fibers in the paper Operation: Intuitive operation via a user friendly touchscreen remote control Easy set-up of web width and water amount Low maintenance costs

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Compaction Custom-made solutions With our variety of granulating systems we produce granulates or compacts in every shape and size for our customers in contract work. Our modern granulating systems consist of roller compacters, pelletizing systems, drum granulators and extruders. Supplementing these are our granulating systems for vacuum packing, in addition equipped with a fully automatic compression force regulation. Through high-tech to the perfect product Our compactor plants made from stainless steel usually consist of the product feed to the roller, a vent unit by vacuuming as well as counter-rotating rollers with continuously adjustable compression force and speed regulation. Here a pre-granulation of pressed slugs, then the fine granulation of pre-granulated goods and the screening of the fine particles under continuous feedback of the screened fine grain are carried out. Our process engineers have multiple ways to customize both the shape and the properties of the final pr

Request for a quoteResults for

Pre-press - Import exportNumber of results

9 ProductsCountries

Company type