- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- powder handling

Results for

Powder handling - Import export

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

A ViTEQ Loss-in-Weight Feeders are designed to ensure a continuous, gravimetric and high tolerance batch dosing of flowable bulk materials that are not hygroscopic, adhesive or interleaving features. The feeders are sSuitable for many bulk materials including those with the following characteristics: fragile (food products) abrasive (coarse powder, pellets, granulate) difficult to handle (like fibres, glass fibres, pharmaceutical powders) Suitable for wherever precise dosing and weighing of the main components and additives is necessary. Ideal in the following industries: Food & Animal Feed Plastics / Chemicals Pharmaceuticals Advantages & benefits less shear and pressure forces Troughs have a dead space-free design quick and easy cleaning, maintenance-free vibration discharge very gentle weighing (volumetric and gravimetric) highly precise dosing high throughputs Construction Technical data WLW-L WLW-M WLW-H Trough length (mm) 275 - 1.100 275 - 1.100 275 - 1.100 Trough wi

Request for a quote

CINCHSEAL EUROPE GMBH

Germany

The newly developed CinchSeal®series is applicable for machines in food production, screw conveyors and other bulk material handling equipment, in the pharmaceutical industry as well as in the chemical industry. It is made of 316 stainless steel or other material according to customer requirements. standard features ✔ lower maintenance due to unique self-adjusting design ✔ prevent leaks and material loss and protect gearboxes, bearings and shafts from damage ✔ mounting pattern suitable for standard bearings ✔ handles dry powders, pastes, slurries, and liquids ✔ USDA- and FDA-certified sealing products for use in meat, poultry, and dairy applications ✔ needs 30% less energy than packing seals ✔ temperature ranges -40 °C to 220 °C ✔ designed to accommodate longitudinal expansion and axial runout of the shaft ✔ pressurization with sealing air, 0.3 to 0.6 bar above the pressure of the operating vessel

Request for a quote

HUGO BRENNENSTUHL GMBH & CO. KG

Germany

Water-jet protected version for universal outdoor use and on sites, IP 65. Guaranteed top quality, for universal outdoor use and on sites. Halogen can be tilted and clamped at any desired angle. With protective grill. Maximum stand stability. Powder-coated. Practical carrying handle. With fitting for cable storage. High quality branded bulb included. This luminaire is compatible with bulbs of the energy classes: B - E. The luminaire is sold with a bulb of the energy class: C. Cable length: 5 m Cable: H07RN-F 3G1,0 Power: 1000 W Luminous flux: 22000 lm Lamp efficacy: 22 lm/W Colour temperature: 3000 K Fittings: R7s Plug-in system: DE + CZ

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The "Metzner RPA 10-SL" is a powerful and flexible press automation system for handling indexable inserts and small ceramic parts for medium to large batch sizes. It has an integrated magazine system for up to ten sintering inserts. Empty sintering inserts are automatically removed from the magazine, loaded and then returned as required. In this way, the powder press automation works independently over a longer period of time without loading and unloading processes leading to a press stop. With its integrated 4-axis SCARA robot, the machine achieves very high system speeds of up to 30 stroke/min. The "RPA 10-SL" is operated conveniently via the integrated control or via the mobile operator terminal. At the push of a button, loaded sintering plates are removed and new ones received. Defined operating data are transferred to the press control via an interface.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

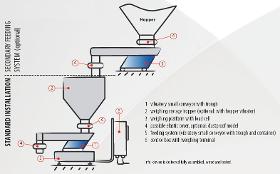

In the plastics compounding and manufacturing process there are many powders (all with different flow properties) which require handling. For the vacuum conveying of both free-flowing and non-free-flowing powders, motan has a solution. The METRO P series of hopper loaders are available in two versions and guarantee reliable and dust-free conveying. The METRO PC system loaders are designed to be integrated into centralised motan conveying systems. The METRO PB single loaders are designed to be used as a “stand-alone” solution. From the material source right through to the point of processing, motan offers the ideal solution for your powder handling requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The latest generation of multifunctional YSTRAL PiloTec process equipment offers you the opportunity to use established production processes on a laboratory scale. Thanks to Conti-TDS technology, powder can be inducted, wetted and dispersed under vacuum, dust-free and in a single operation. Easy-to-use swappable tools enable operation using the innovative Multi-Z or Z-Inline process with high-precision multi-stage shear ring systems. Established procedures and a specific energy input independent of the batch size guarantee excellent and consistent results. These can be easily transferred to production scale - a safe scale-up to ystral plant construction. The modular design enables extension to the PiloTec-Plant process plant with ystral mixing technology, systems for handling powders and liquids, measuring technology and sensors, lifting stands as well as other modular components.

Request for a quote

MÜLLER GMBH

Germany

Powder handling without creating dust is always a challenge in industrial processes. Müller dust-free docking systems offer you a simple and reliable solution to this problem. The Müller docking system centers around the silicone rubber cap, whose special lip seal ensures reliable, flexible and dust-free docking. This simple docking method used in conjunction with other Müller components enables a wide variety of dust-free product transfers to be carried out cost-effectively. Standard version Simple docking Accurate positioning not necessary Key to sketch: A - product B - into machine C - silicone elastomer cap D - system inlet tube / cone E - lip seal Version with hopper pressed against lip seal Simple docking if system becomes slightly pressurized Key to sketch: A - product B - into machine C - silicone elastomer cap D - system inlet tube / cone E - lip seal pressed down Telescopic version Simple docking with telescopic intermediate tube Key to sketch: A - product B - into...

Request for a quote

MÜLLER GMBH

Germany

All butterfly valves are made of stainless steel and available in sizes from ND 100 up to ND 250. The butterfly valves are designed for powder handling in the pharmaceutical and chemical industry and meet cGMP and FDS standards. The compact design and the massive clamp closing with bracket allows an assembling without any tools. 7.6 / 01 Valve Type MC

Request for a quote

MÜLLER GMBH

Germany

Powder handling OEB Level 3+4 At last a stable and robust split butterfly valve system for emptying and filling your highly potent or toxic media. Light to handle and safe to use. You can rely on the Müller Containment Valve to safeguard the health of your employees even as you maintain the purity of your product and protect the environment. The Müller Containment Split Butterfly Valve MCV is in two halves: the active and passive disks. The active disk incorporates the mechanical system for locking both halves together and a manual lever or actuator for opening and closing the valve. The active half of the valve is fitted to the vessel filling or emptying nozzle, and the passive half to the intermediate bulk container. The two halves of the butterfly valve (active and passive disks) must be docked together in order to open the valve. The ruggedly constructed and GMP-compliant locking device ensures accurate location and the safe docking when the two halves are connected. When...

Request for a quoteResults for

Powder handling - Import exportNumber of results

10 ProductsCountries

Company type