- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plates machining

Results for

Plates machining - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used in printer accessories, after machining, mask the hole then process anodize.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These accessories are used for mechanical valves.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used for the precision accessories,after process by 3-4 axis machining,then going for the anodize and chrome plating.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

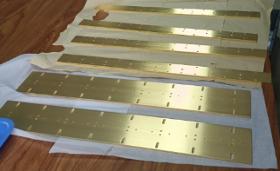

These accessories were made by copper, after CNC machined, then process brushing ,finally do the gold-plating .

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts made by stainless steel.after CNC turning machining, then doing the nickel plating.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

THERMA THERMOFÜHLER GMBH

Germany

Use: Designed for soldering or crimping on mineral insulated sheath cable or crimping on insulated wire. Construction: Brass machined, nickel plated insert with 0.1 mm tolerance on the cable OD.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

High performance cartridges and heating elements are excellently suited to direct heating of all kinds of tools. Area, ring and barrel heaters are suitable for heating boilers and moulds, tools, die plates, machine parts and a range of other purposes. They can be manufactured individually to size, voltage and output specifically for your application. High performance cartridges are suitable for tool heating in the many different fields in which a specific compatible operating temperature is required. High performance cartridges are essential in the thermal machining process field. High surface loadings facilitate a correspondingly high performance in a small installation area, at operating temperatures of up to 750°C at the heating cartridge jacket. We produce diameters between 6 mm and 45 mm to order. Different types of feed also allow high performance cartridges to be matched to the relevant installation situation.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The cross-section range is reduced from 0.05 up to 2.5 mm² (AWG 30 – 14) and a special front plate is added. This machine can be used for shorter infeed lenght of 15 mm + stripping length.

Request for a quote

HEINZE & STRENG GMBH

Germany

In the wire and cable industry, wear plates are an important component in the production process. To increase the lifespans of the plates, we subject them to thermal treatment. The “slip-in” design further minimizes the repair costs. Wear plates available from Heinze & Streng with conventional or “slip-in” design.

Request for a quote

GIGAHERTZ OPTIK GMBH

Germany

Synthetic diffuse reflecting material in different gray scales. Features: Wide spectral range from 250-2400nm. Gray scales from 2% to 70%. Raw material in block and plate shape. Machined reflectance standards.

Request for a quote

GIGAHERTZ OPTIK GMBH

Germany

Synthetic, white diffuse reflective plates. Features: High degree of reflectance from 250-2400nm with 98% at 555nm. Precise machined plates in different sizes.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018, FDA, HACCP, CE, UL SPECIFICATION HMI, SCADA System. Centrifugal pumps. CIP System. Apparent piping and extension system. ALFA LAVAL pasteurization gasketed plates. Diaphragm steam valves Copper plates heat exchanger. PT100 Sight glass. Our machine has been design to pasteurize Milk, Yogurt, Ayran and Juice. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

KLN ULTRASCHALL AG

Germany

In the last few years KLN has enlarged their hot plate welding machine program „TOOLMASTER“ and their vibration welding machine program “LVW” by the infrared welding program. The KLN machine program of „pure“ IR welding is based on the hot plate machine program „TOOLMASTER”. Machines for infrared heating should be equipped with servomotor drives in order to guarantee simple, quick and exact positioning. For welding by means of infrared technology short-wave (0,78-2 μm) as well as medium-wave (2-4 μm) infrared radiation of the spectrum can be used. This depends particularly on the radiation absorption capacity of the respective polymer material. The more precisely the radiator is adapted to the absorption capacity of the polymer material, the higher is the degree of efficiency, that means the conversion into warmth. Short waves are absorbed in deeper layers of the material, whereas medium waves heat it up more at the surface.

Request for a quote

SMI HANDLING SYSTEME GMBH

Germany

mini smilift, allows you quick and frequent movement of loads of up to 60 kg either in cartons, boxes, and bins or as individual items such as plates and machined parts. This compact unit is light and flexible with one-hand-control for pick and place applications in frequent handling operations. It can be equipped with a range of attachments for use with many types of load in production, warehouse and despatch areas. mini smilift is easily and quickly installed and can be integrated into existing installations and work flows.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

The peel force is a critical parameter for every user of Tape & Reel. If the peel force is too low, the cover tape will not stick on the carrier tape properly and the components may fall out of the pockets. A too high peel force will cause costly down times at the pick & place machines. The KT 5000 peel force tester from KTECH is the ideal tool to measure the peel force on your production floor. For measuring, a strip of the carrier tape is loaded into the KT 5000 and the cover tape is attached to the sensor. The constant movement of the carrier tape is done with a sprocket wheel. The movement speed is controlled with an encoder. The design of the KT 5000 guarantees the same peel angle and the same peel point during the whole measurement. Before each run, the KT 5000 is doing a selfcalibration of the sensor. The measured values are transferred to a PC via a serial RS232 interface. A green bar on the screen shows a good result, if the measurement is out of limit, the bar is red.

Request for a quoteResults for

Plates machining - Import exportNumber of results

16 ProductsCountries

Company type

Category

- Typographic and photographic plates - machines for manufacturing (2)

- Packing and packaging - machinery and equipment (1)

- 3D scanner (1)

- Astronomy - instruments and equipment (1)

- Cables - accessories (1)

- Connectors, electronic (1)

- Food industry - machinery and equipment (1)

- Gear pumps (1)

- Hardware for furniture (1)

- Induction heating systems (1)

- Lifting - vehicles (1)

- Ultrasound systems - Processing plastics (1)

- Video surveillance systems (1)