- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plate heat exchanger

Results for

Plate heat exchanger - Import export

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

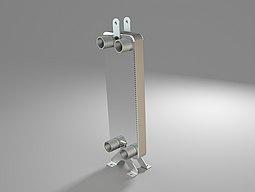

• operating temperatures up to 600°C (standard) • completely made of stainless steel • heat recovery factor up to 85% • pressure-resistant up to 150 mbar • completely welded • high degree of efficiency • without seelings • up to 100% gas-tight • low maintenance • small construction volume • flexible coordination due to single-item or small-lot production • distance between plates from 3.5 mm to 7 mm • available in the structural shapes K, L, U and LU • complete seperation of the two gas flows • different current lines possible • different volume flows for exhaust and feed air, applicable for the temperature control of useful heat Structural shape In principle, the shape is arbitrary. The choice takes place after consulting with the customer and with similar power are no costs involved. It depends on the technical demands of the application. The structural shape X (crossflow) isn't possible with the ´ THERMO GAS System. Shape LU This structural s

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

• operating temperatures up to 600°C (standard) • completely made of stainless steel • heat recovery factor up to 85% • pressure-resistant up to 150 mbar • completely welded • high degree of efficiency • without seelings • up to 100% gas-tight • low maintenance • small construction volume • flexible coordination due to single-item or small-lot production • distance between plates from 3.5 mm to 7 mm • available in the structural shapes K, L, U and LU • complete seperation of the two gas flows • different current lines possible • different volume flows for exhaust and feed air, applicable for the temperature control of useful heat no costs involved Shape U This structural shape is especially qualified for small plate heat exchangers. This structural shape is although qualified for plate heat exchangers which should streamed vertically.

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

• operating temperatures up to 600°C (standard) • completely made of stainless steel • heat recovery factor up to 85% • pressure-resistant up to 150 mbar • completely welded • high degree of efficiency • without seelings • up to 100% gas-tight • low maintenance • small construction volume • flexible coordination due to single-item or small-lot production • distance between plates from 3.5 mm to 7 mm • available in the structural shapes K, L, U and LU • complete seperation of the two gas flows • different current lines possible • different volume flows for exhaust and feed air, applicable for the temperature control of useful heat Structural shape In principle, the shape is arbitrary. The choice takes place after consulting with the customer and with similar power are no costs involved. It depends on the technical demands of the application. The structural shape X (crossflow) isn't possible with the ´ THERMO GAS System. Shape L This plate heat exc

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

• operating temperatures up to 600°C (standard) • completely made of stainless steel • heat recovery factor up to 85% • pressure-resistant up to 150 mbar • completely welded • high degree of efficiency • without seelings • up to 100% gas-tight • low maintenance • small construction volume • flexible coordination due to single-item or small-lot production • distance between plates from 3.5 mm to 7 mm • available in the structural shapes K, L, U and LU • complete seperation of the two gas flows • different current lines possible • different volume flows for exhaust and feed air, applicable for the temperature control of useful heat Structural shape In principle, the shape is arbitrary. The choice takes place after consulting with the customer and with similar power are no costs involved. It depends on the technical demands of the application. The structural shape X (crossflow) isn't possible with the ´ THERMO GAS System. Shape K An absolute classic

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: K 55 Manufacturer: APV Description: Plate heat exchanger

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: P 45 RB Manufacturer: Alfa Laval Description: Plate heat exchanger

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: VT 40 Locin Manufacturer: GEA Ahlborn Description: Plate heat exchanger

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: Sigma 30/32 Manufacturer: Schmidt Description: Plate heat exchanger

Request for a quote

LIQUOSYSTEMS GMBH

Germany

Plate heat exchangers are a part of the wort cooling in the beer production process. Made of stainless steel. The heat exchangers are vacuum-hard wired. They must be made of stainless steel plates and copper solder, which are looking at stainless steel.

Request for a quote

ANTHERMO GMBH

Germany

Temperation of fluids Pillow plates are used everywhere where liquids must be temperated. In dependence of application the liquids can be cooled or heated. Cause of this wide range of applications pillow plates are used in the process industry, in the cooling industry and in a lot of other industries. Pillow plates are also know as heat exchanger plates, evaporator plates, cooling plates /sheets and thermo plates / sheets. Pillow plates as air-/water-heat exchanger Additionally to the temperation of liquids pillow plates are also used as air-/liquid heat exchangers. In case of polluted or wasted air and if there are high demands for cleaning, more and more pillow plates are used as air-/water-heat exchanger. The large exchange surface and the good possibilities for cleaning are important features for this type of heat exchanger.

Request for a quote

R+L HYDRAULICS GMBH

Germany

Working pressure up to 30bar Temperatur up to 195 °C Maximal 300 plates Various brackets Special versions on demand

Request for a quote

ANTHERMO GMBH

Germany

Generate cold water / flake ice continuously Proven use Falling film chillers have been used in various industrial sectors for many years. Water runs over the heat exchanger plates from a trough arranged above the heat exchanger plates. This enables a continuous heat transfer between the water and the cooling medium. Outstanding advantages The arrangement of holes in the upper tub enables targeted water distribution on the heat exchanger plates. The construction using a perforated tub has the further advantage that no contamination occurs and the liquid to be cooled is evenly distributed. Made of stainless steel The trickle cooler is made entirely of stainless steel. You can choose between different materials (see data sheet). Low boiling delay Our trickle coolers are characterized by the fact that the boiling delay is low in flooded operation, whereby overheating can be selected in dry expansion operation.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Polyester heaters also referred to as Polyester film heaters or Polyester foil heaters consist of an electrically conductive ink between two insulating respectively carrier layers of polyester. With a maximum size of 600 x 1000 mm, their average height is only 0.2 mm. As the picture examples show, practically any shape and type of cut-out is possible. Polyester foil heaters are resistant to permanent temperatures of up to 90°C (max. 100°C for short periods). It is generally not possible to predict which temperature a Polyester heating element will reach in the application, as there are extremely many influencing factors. These include not only the power, but also the mass and type of goods to be heated, the ambient temperature, air currents, the type of mounting and, of course, the control technology. Typical applications for Polyester heaters are e.g. cup warmers in coffee machines, mirror heaters, plate heat exchangers, flat applications with a target temperature below 90°C.

Request for a quote

KELVION HOLDING GMBH

Germany

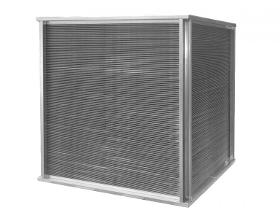

Our brazed plate heat exchangers offer customized solutions for a wide variety of applications. Thanks to the automated production and compact design of our brazed plate heat exchanger series, we can put together an individual heat exchanger for you within a very short time. The latest technology and decades of experience of successful applications guarantee highest quality, cost efficiency and reliability.

Request for a quote

KELVION HOLDING GMBH

Germany

Our gasketed plate heat exchangers combine passion, scientific curiosity and technological expertise. The facts: High efficiency at low operating costs, versatile application possibilities with lower investment costs and maximum flexibility. Our efforts to continuously develop the gasketed plate heat exchanger-series further are aimed at meeting your thermodynamic and hydraulic performance needs and to ensure maximum economic efficiency. Our wide range of plate corrugations, connection sizes, materials, plate lengths and widths enable an ideal configuration according to your exact requirements. Additionally, our gasketed plate heat exchangers come with a maintenance-friendly assembly and sealing technology, ensuring low service and maintenance costs.

Request for a quote

KELVION HOLDING GMBH

Germany

Our fully-welded plate heat exchangers make a convincing case due to their minimal size, outstanding thermal transfer coefficients and comparatively minimal investment costs. They are particularly robust and require only minimal cleaning and servicing. Their design advantages come into play especially in areas, in which, in addition to the output, load capacity is also a requirement.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

CLEAN PROCESS WATER WITH GWK KU-PLANTS Water is one of the key elements in our daily life. It is a supplier of the most various requirements, also in the area of technical and mechanical production. Water is an excellent cooling medium. ku-plants from gwk utilise the cooling energy provided by water to carry away heat from production machines in the most troublefree and cost effective way possible. Removing side effects Fresh water from a well, from rivers and from other surface reservoirs is always saturated with oxygen and includes a large number of minerals and suspended particles which can block up the cooling channels in production units through corrosion or by producing deposits. ku-plants from gwk do not allow such problems to arise. A plate-type heat exchanger made of stainless steel separates the clean closed circuit that is used to cool the production from the natural fresh water circuit that is contaminated with all kinds of impurities.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MSE FILTERPRESSEN GMBH

Germany

The hot filter press combines the standard process steps of a membrane filter press, (filtration, filter cake washing and squeezing), with the additional function of a thermal filter cake drying (TCD). As a result, all process steps are carried out in one plant, the hot filter press. Dewatering and drying of the resulting filter cake is thus done without a downstream drying process. Cost-intensive and time-consuming vacuum contact drying is therefore no longer necessary. FUNCTIONAL PRINCIPLE OF THE HOT FILTER PRESS – WITH THERMAL FILTER CAKE DRYING In contrast to the conventional method, the system consists of membrane filter plates and heat exchanger plates, which are installed alternately in a filter press. For thermal drying, hot steam and/or oil is applied to the working space behind the membrane and the filter cake is thermally dried accordingly. The advantage of this process is that a high dry matter content (DM content) of over 90% is achieved.

Request for a quote

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

Tubes wound into a spiral shape Coaxial heat exchangers consist of two or more pipe coils, which are routed into one another and wound up in a spiral shape. The primary medium runs in countercurrent to the secondary medium. Fast temperature exchange This countercurrent design achieves a very rapid temperature transition with high efficiency between the liquids. Due to the spiral shape, the rapid temperature exchange between the liquids is achieved in a very small space. No cleaning or maintenance required Another advantage is the encapsulation of both liquids from environmental influences. There is practically no cleaning or maintenance effort due to pollution from the environment. The coaxial heat exchanger also does not require any seals that require maintenance. Condenser or evaporator function Coaxial heat exchangers can be used for both condenser and evaporator functions.

Request for a quote

ANTHERMO GMBH

Germany

Know-how for special applications There are applications with very special requirements for the heat exchanger. Due to its decades of experience, Anthermo GmbH has the necessary know-how to be able to build special heat exchangers for special applications. So every year we build numerous heat exchangers that are a bit off the standard. Dimensioning with EDP programs With the help of EDP programs, Anthermo GmbH is also able to dimension and technically design special heat exchangers. The technical design and dimensioning is strictly based on the specifications and requirements of the customer. After the design, a three-dimensional CAD model is created. The CAD drawing approved by the customer forms the basis for production with the most modern IT-supported production systems.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of liquids Tube coil heat exchangers (so-called tube cooling coil heat exchangers) are generally used to control the temperature of liquids. This system can also be used to heat or cool liquids in a controlled manner. Due to their special shape, pipe coil heat exchangers are sometimes also called hairpin heat exchangers. Inexpensive applications The simple and solid structure enables it to be used in cost-effective applications. Coiled tube evaporator systems are ideally suited for brine and glycol applications. Classic variant Coiled tube evaporator systems are a classic and proven variant in the field of heat exchanger systems. Coiled tube heat exchangers are often used in ice storage systems or in the production of cold water units. In ice storage systems, coils can be used to achieve an even build-up of ice around the coils.

Request for a quote

ANTHERMO GMBH

Germany

Temperature exchange between a gas and a liquid In the case of air-water heat exchangers (also called gas-water heat exchangers), there is a temperature exchange between a gas (usually air) and a liquid. Finned heat exchangers can cover various areas of application: - heating and evaporating, - cooling and condensing as well as heat recovery. In this context, lamellar heat exchangers are also called air heaters or air coolers. Air-water heat exchangers are often also used as exhaust gas heat exchangers or flue gas heat exchangers in order to recover the energy from warm or hot exhaust gases. Lamella packs for a large exchange area In order to achieve the largest possible exchange surface between the air and the medium (liquid) within the heat exchanger, lamellas or lamella packs are attached to the pipe system.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-water heat exchangers for industrial use Three types of air-water heat exchangers Three different designs o air-water heat exchangers The Anthermo GmbH delivers three different designs of air-water heat exchangers: Finned tube heat exchangers Lamella heat exchangers Straight tube heat exchangers These heat exchangers are designed in a way, that inside the tube water or another liquid circulates. The air flows around outside the tubes or the fins/lamellas. The connection between the fins and the tube is used to enlarge the space for heat transfer between the liquid and the gas fluid. The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-water heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-air heat exchanger for the industry (up to 1.000°C) Hot outgoing air and cold incoming air Very often hot exhaust gas gets out in the environment without any use. On the other hand cold incoming air must be lead into the production process and shall be warmed. This occurs for example very often within drying technology. In this case air-air heat exchangers can be used very efficient in heat recovery. As result you have great potential to save energy expenses. Three types of air-air heat exchangers The Anthermo GmbH delivers three types of different air-air-heat exchangers: cross-flow heat exchanger straight-tube heat exchanger flat-tube heat exchanger The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-air heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

ANTHERMO GMBH

Germany

Air heat exchangers as finned tube heat exchangers Heat transfer between a gaseous media and a liquid Finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air) and a liquid (for ex. water) takes place in the air-/water heat exchangers. To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. Very often air-/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube heat exchangers can also be used as air heater, air cooler or condenser.

Request for a quote

ANTHERMO GMBH

Germany

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of gaseous and liquid media Flat tube heat exchangers are generally used as air / air or air / liquid heat exchangers. Flat tube heat exchangers are used where the (exhaust) air is polluted and the installation space is limited. In heat recovery in particular, there are numerous applications for flat tube heat exchangers as so-called exhaust gas / exhaust air heat exchangers. Little installation space and less pressure loss While the rows of tubes in smooth tube heat exchangers consist of round tubes, the rows of tubes in flat tube heat exchangers have a special profile (see illustration). This special tube profile offers advantages over the round profile in certain applications. Flat tube heat exchangers require less installation space than smooth tube heat exchangers with the same exchange area and are therefore also lighter.

Request for a quote

APROVIS

Germany

What you can expect from an APROVIS process gas heat exchanger: - Suitable for low and high temperature ranges - Operating pressures up to 160 bar - Compact design for use in confined spaces - Suitable for a wide range of gases - Implementation of customised solutions

Request for a quoteResults for

Plate heat exchanger - Import exportNumber of results

39 ProductsCountries