- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plastic processing machines

Results for

Plastic processing machines - Import export

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of slow-running rolling and friction bearings, rollers, transport chains or sliding surfaces on kiln trolleys, bakery machines, drying tunnels, foundry machines, boiler firing systems, plastics processing machines for welding and soldering machines etc. Advantages and benefits Highly effective due to optimum temperature-stable silicone grease formula Excellently suited for grease lubricating points subject to high-temperature loading Broad range of uses outside normal grease performance areas

Request for a quote

KLN ULTRASCHALL AG

Germany

We work with you to develop the best possible solution for your project based on standard systems or modular functional modules. We have developed solutions for welding, punching, riveting, drilling, wrapping, flanging, handling and many other processes. Your task is most important for us and our technicians will try find together with you a solution meeting the requirements in quality, cycle time and cost. Examples of special systems: • final processing machines for plastic fuel tanks • rotary table machines for vibration welding, infrared welding, ultrasonic welding and hot plate welding • edge-welding machines for textile back injection molded parts • ultrasonic or mechanical punching machines • infrared welding machines in modular design for welding of several parts in one go • fully automated operating cells e. g. with feeding technology and robot handling

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

JETBOXX® plastic granulate dryers are compressed air based dry-air dryers for mounting directly on the feed section of the processing machine. The JETBOXX® technology guarantees perfect drying results thanks to plastic-specific and throughput-dependent dryer settings. The dryers are available with a volume of 30/50/75 litres and can be optimally adapted to your requirements with a large number of options from the JETBOXX® system. The JETBOXX® control provides a database for plastics, conveying control, week timer, fully automatic decrease and resume of the drying intensity when production is interrupted (overheating protection), automatic restart with preheating program in 1- or 2 shift operation, dew point measurement, speed dial programs, personal programs, and many more. Compressed air conveyors of one or two components with or without dedusting function are available. The conveying control is already included.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

Mobile plastic granules dryers from the JETBOXX® system are available with a volume of 30/50/75/200 litres and can be optimally adapted to your requirements with a large number of options. They can be used anywhere, where top-mounted dryers fail because of weight / or space reasons, and flexibility is required. When changing the setting of task, the components can be combined easily or used for example as top-mounted dryers. The compressed air-based dryers are maintenance-free and provide professional functions such as: plastic-specific and throughput dependent dryer settings, database for plastics, conveying control, week timer, overheating protection, dew point measurement, speed dial programs, personal programs, and many more.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

"The demand for excellent mixing quality and consistently accurate dosing is a must when combining additives to the virgin material at the processing machine. The volumetric MINICOLOR V dosing and mixing units meet and exceed these requirements. Mounted at the feed throat of the plastics processing machine, the units require very little space. Depending on need and requirement, screw or disc dosing modules can be installed at the mixing neck. Disc dosing is ideal for translucent and opaque parts as well as for dosing very small quantities."

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

"The demand for excellent mixing quality and consistently accurate dosing is a must when combining additives to the virgin material at the processing machine. The gravimetric MINICOLOR G dosing and mixing units meet and exceed these requirements. Mounted at the feed throat of the plastics processing machine, the units require very little space. Depending on need and requirement, screw or disc dosing modules can be installed at the mixing neck. Disc dosing is ideal for translucent and opaque parts as well as for dosing very small quantities."

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

"The demand for excellent mixing quality and consistently accurate dosing is a must when combining additives to the virgin material at the processing machine. The volumetric MINIBLEND V dosing and mixing unit meets and exceeds these requirements. Mounted at the feed throat of the plastics processing machine, the unit requires very little space. Disc dosing is ideal for translucent and opaque parts as well as for dosing very small quantities."

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Combining additives with the virgin material at the processing machine requires excellent mixing quality and consistently accurate dosing. These requirements can be achieved and exceeded with the volumetric MINICOLOR swift V dosing and mixing unit. The units are mounted at the feed throat of the plastics processing machine and are space-saving.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

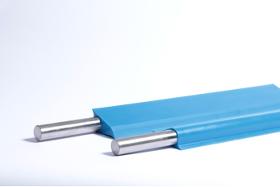

Available with stainless steel axle with suspension for permanent belt contact. We will be happy to assist you with the initial installation. Thanks to an approval according to various EU regulations, we can offer you a top material with the casting polyurethane Intec E for extreme applications in contact with food. Whether for small quantities from 1 or for large-volume components weighing up to 900 kg - Intec E covers the entire range in hardnesses from 45 Shore A to 93 Shore A.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

Hedgehog fingers/ hedgehog mats/ hedgehog bands are used for safe transport of sensitive and pressure-sensitive fruit as well as vegetables. The hedgehog tapes can even be glued with a PVC carrier tape. Thanks to an approval according to various regulations of the EU, we can offer you a top material with the casting polyurethane Intec E for extreme applications in contact with food. Whether for small quantities from 1 or for large-volume components weighing up to 900 kg, Intec E covers the entire range in hardnesses from 45 Shore A to 93 Shore A. If you need large quantities, we offer food contact approved materials in injection molding with up to 6 kg weight and 1.5 m² area.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

Pipe lining made of cast polyurethane (75 Shore A). The lining is held from the outside via two flanges. Due to the extremely good abrasion resistance you have proven our linings!

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

The screw elements can be mounted on a square shaft. You transport bulk materials into bins or silos via rotary movements.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

In the plastics compounding and manufacturing process there are many powders (all with different flow properties) which require handling. For the vacuum conveying of both free-flowing and non-free-flowing powders, motan has a solution. The METRO P series of hopper loaders are available in two versions and guarantee reliable and dust-free conveying. The METRO PC system loaders are designed to be integrated into centralised motan conveying systems. The METRO PB single loaders are designed to be used as a “stand-alone” solution. From the material source right through to the point of processing, motan offers the ideal solution for your powder handling requirements.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

With the METRO G/F/R material loaders, large quantities of granulate, dusty regrind and flakes can be conveyed automatically to the hopper of a processing machine, drying bin or day bin. Filters with sophisticated cleaning technology and large outlet flaps guarantee trouble-free operation. Via the hinged lid, free from vacuum and material hoses, the loaders can be quickly and easily cleaned during material changes.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

With the METROFLOW gravimetric material loader, plastic processors can automate important areas of the production process cost-effectively and efficiently. The METROFLOW weighs every single load and evaluates the results, with a guaranteed precision of <1%. This improves the entire material management process and allows for full traceability. The material loaders come in 6, 10 and 30 liter volumes. The METROFLOW series is part of the motan range of products and systems for all stages of management, conditioning and preparation of plastic granules. The design quality, plus the engineering, ensures high performance and reliable operation.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Metal separators from motan can be installed at various locations in a production and for multiple applications. The metal separators prevent damage to your processing machine, tooling and end-products

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

With automatic continuous punching machines, machine and tool merge into a high-performance system with high output and remarkable flexibility. Whether sealing profiles for the automotive industry, applications for furniture, or household appliances – complex trimming is often required here. Thanks to the Metzner automatic throughfeed punching machines, processing operations such as contour cutting, drilling and milling can be integrated into a throughfeed system. All these machines store all machining parameters and machine settings in a machining recipe. When starting production, an integrated barcode scanner activates all presettings on the basis of the working papers and simultaneously reports the correct tool and material on the machine display. The barcode also contains the required quantities and lengths. Thanks to well thought-out quick-change systems, tools and materials are generally changed within no more than 30 seconds, minimizing downtimes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Plastic processing machines - Import exportNumber of results

18 ProductsCountries

Company type