- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- panel supplies

Results for

Panel supplies - Import export

TROTEC GMBH

Germany

The infrared heating panel TIH 900 S supplied in TÜV-tested quality comes with all the references to be expected of a branded heating panel. This includes i.a. the efficient heating procedure with environmentally sound IR-C radiation, where 100 % of the electrical energy input is converted into heat output. Moreover, the TIH 900 S generates a cosy and clean warmth – without noises, smells, condensate or the unpleasant circulation of dust. For like the sun the heating panel generates direct heat by means of infrared radiation, which does not heat the ambient air, but rather all the items in the room (besides persons also walls, ceiling, floor and furniture) which then gradually emit the stored heat into the room.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 1800 is a fully automated foil application and sealing machine, suitable for plastic, tin or glass containers. mobile base frame feed conveyor with feed control synchronised star wheel stand with receptacles for the containers as form parts adjustable outer ring for guiding containers through the machine sequence foil magazine for stackable pre-cut Ballerstaedt seals pneumatically driven foil dispenser with a precise, maintenance free 180° reverse gear for removing the seals from the magazine, applying them to the sealing edge and fixing them with a pre-sealer sealing station for closing the containers with regulation of the sealing temperature, pressure and time for optimal setting of the seal parameters, conductive, optional also inductive exit conveyor for the containers central height adjustment of the magazine plate to adjust it to the respective container height all-over protective coating control panel with electrical supply unit

Request for a quote

PANEL SELL GMBH

Germany

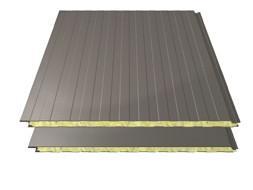

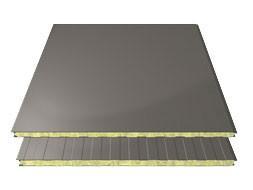

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BALLERSTAEDT & CO. OHG

Germany

The BaCo 1800 is a fully automated foil application and sealing machine, suitable for plastic, tin or glass containers. • mobile base frame • feed conveyor with feed control • synchronised star wheel stand with receptacles for the containers as form parts • adjustable outer ring for guiding containers through the machine sequence • foil magazine for stackable pre-cut Ballerstaedt seals • pneumatically driven foil dispenser with a precise, maintenance free 180° reverse gear for removing the seals from the magazine, applying them to the sealing edge and fixing them with a pre-sealer • sealing station for closing the containers with regulation of the sealing temperature, pressure and time for optimal setting of the seal parameters, conductive, optional also inductive • exit conveyor for the containers • central height adjustment of the magazine plate to adjust it to the respective container height • all-over protective coating • control panel with electrical supply unit

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 075/Ri Forming Machine for DIP Components Description The Streckfuss forming machine type A 075 Ri is designed to form the leads of dual in- line package components utilizing a tube- to- tube feeding configuration. The machine is able to process DIP's in a wide range of component sizes (from 7,62 mm up to 19,9 mm). The adjustment of lead span can be preset and is displayed on a digital panel. The supply of components can only be done by the use of component tubes. The processing speed is continuously variable. Up to 5.000 components can be processed within an hour. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 075 Cutting & Forming Machine for DIP Components Description The Streckfuss cutting and forming machine type A 075 is designed to cut and form the leads of dual in- line package components utilizing a tube- to- tube feeding configuration. The machine is able to process DIP's in a wide range of component sizes (from 7,62 mm up to 19,9 mm). The component leads are first formed to the desired lead span and then cutted to desirable length. The adjustment of lead span and cutting parameters can be preset and are displayed on a digital panel. The supply of components can only be done by the use of component tubes. An empty component tube picks up the processed components. The processing speed is infinitely variable. Up to 3.500 components can be processed within an hour. Components

Request for a quoteResults for

Panel supplies - Import exportNumber of results

9 ProductsCountries