- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- paints and varnishes

Results for

Paints and varnishes - Import export

ROCHOLL GMBH

Germany

YOU TAKE CARE OF THE COLOR, WE TAKE CARE OF THE QUALITY For paint tests, we are able to produce paint test panels that are made of various materials, offering a wide range of coatings, shapes and surface finish options. Of course we attach great importance to meeting your requirements. Upon request, we supply bright-finish, degreased or pre-treated panels. Moreover, test panels can be provided with drilled holes or rounded corners. You can also order test specimens made of any common materials such as wood, glass, aluminum, steel or plastic for the TABER abraser test. From various metals From various plastics With boreholes Bare or pretreated Degreased and vacuum-packed Various sizes upon request Coil-coated aluminum or sheet steel upon request

Request for a quote

FREILACKE EMIL FREI GMBH & CO. KG

Germany

Extra value thanks to energy-efficient powder coatings. Energy-efficient powder coatings are primarily low-temperature powder coatings or fast-reacting powder coatings (NT). Many users of such powder coatings look for the opportunity to lower baking temperatures, thereby achieving direct reductions in oil and gas consumption. However, energy-efficient powder coatings can also increase productivity within the coating system. The baking oven frequently constitutes a bottleneck point in the process. At low baking temperatures, the use of powder coatings can significantly shorten the oven throughput time, thereby increasing the line speed. Take off into the future with new application fields. With energy-efficient powder coatings, you can take advantage of new products and application fields for your company. The range of parts can also be expanded by their usage.

Request for a quote

FREILACKE EMIL FREI GMBH & CO. KG

Germany

Coating with a FreiLacke electrodeposition coating (EC) is the economical and environmentally-friendly method of protecting and embellishing metal substrates. The procedure is principally suitable for all conductive metals and alloys. The component to be coated can be connected either as a cathode (cathodic electrodeposition coating) or as an anode. Electrodeposition coating as a method of corrosion protection is used in the automotive industry as well as many other sectors. The EC method enables process recycling and can be fully automated. Ranging from heaters to switch cabinets and shelves – FreiLacke electrodeposition coatings give surfaces great mechanical strength and are ideal for customer-specific developments.

Request for a quote

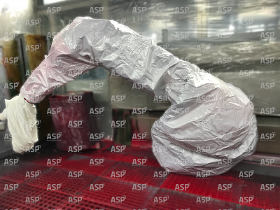

ASP GERMANY

Germany

Optimal protection of the robot against paint and varnish mists Prevents paint deposits on treated parts High paint or varnish absorbency power Stretchable sleeve covers available in custom lengths or rolls (variable length depending on the model) Multiple widths available The “shaped” sleeve can be adapted to perfectly fit the robot’s morphology ATEX-certified paint sleeves The disposable TTY or TYSO fabrics are paint-resistant and 100% recyclable PE. Depending on the ATEX requirements, customers can choose between an insulating TYSO fabric or an antistatic TTY fabric. Controlled cutting, inspection and packaging, process compatible with paint workshops (no fibers) Absorbent foams for handling tools in varnish applications TSB13 or FPB flexible and paint- and solvent-resistant undercovers.

Request for a quote

LUTZ PUMPEN GMBH

Germany

Description:The double diaphragm pump is suitable for pumping small quantities in the laboratory sector and for occasional filling processes. * typical applications: Chemical circulation and feed, liquids with solid particles such as paints and lacquers, electroplating liquids, etc. * integrated muffler up to model size AODD 1" * highly resistant TFM (PTFE) diaphragms (modified PTFE) Features & Benefits * high hydraulic performance * maintenance-optimised design and simple installation * self-priming (even when dry) * reinforced elastomers and thermoplastic diaphragms * absolutely oil-free * non-stalling operation

Request for a quote

CRYOSNOW GMBH

Germany

• For automized applications • CO2 consumption is controlled by pressure and temperature • Compact design, overall length 134 mm (5.3") • Customer-specific robot adapter • Weight without robot adapter 3.9 kg (8.7 lb) • No water condensation due to high efficient thermal insulation • Process reliable and maintenance-free in permanent operation • Cleaning width 200 mm (7.8")

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements and builds customised plants and systems for the paint industry and the varnish industry. Our plants and systems for dosing liquids and solids in the paint and varnish industry offer high dosing accuracy and perfect reproducibility. We meet the high demands of our customers through the use of high-quality materials and precise workmanship. Application of plants and systems for the paint industry and the varnish industry: Storage, mixing, dosing and application of paints and varnishes Special dosing valves and dosing pumps for paints and varnishes

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Functional and decorative coating systems In addition to coatings for Coil Coating applications and related areas, SI-Coatings GmbH develops and produces individual paints and varnishes for any application. These are technical, functional and decorative coatings.

Request for a quote

INOX VERTRIEBS GMBH

Germany

The INOX® Polymer Dewaxer IX 5000 effortlessly removes all synthetic polymer waxes on new and used cars. The dewaxer is alkaline and suitable for all types of paints and varnishes. Due to its special composition, the dewaxer is very gentle on paint and leaves no traces after use.

Request for a quote

LUTZ PUMPEN GMBH

Germany

For liquids that have to be mixed before processing and then pumped or contain small solids, the new Diaphragm pumps with an integrated air-operated Double diaphragm pump is the perfect solution. The mixing and pumping process takes place via a suction and mixing tube and a 3-way valve. The pre-assembled system is immediately ready for operation with a few simple steps and is also suitable for explosive liquids. * Mixing and pumping integrated in one system * stufenlose Regelung der Folgeplatte über Steuerventil * Media examples: Paints and varnishes, emulsions, dispersions, suspensions, water/oil mixtures, liquids with increased viscosity and solids content Features & Advantages * Quick installation and time saving through easy handling * Compact design * Base plate offers good stability on the container lid * Easy to insert into the 2" bunghole of the container by balancer or overhead crane * No further mixer necessary

Request for a quote

LUTZ PUMPEN GMBH

Germany

The flow meter with touchscreen display and backlighting impresses with its simple, needs-based display and operability, multilingual interface and compact design. Thanks to the rotating oval wheel meters and the magnets placed on the measuring wheels, it enables precise measurement of the volume flow and measures non-flammable liquids such as alkalis, mineral oils, hydrocarbons and solvents as well as highly flammable liquids precisely, quickly and, above all, efficiently. * Optionally available in explosion-proof design * Examples of media: Paints, varnishes, mineral oils, acids, alkalis, mineral oils, solvents * Measurement according to the oval gear principle * High measuring accuracy due to overrun correction * Touch screen display with self-explanatory, multilingual user interface * Relay module for volume preselection can be retrofitted at any time * Approved in accordance with ATEX Directive 2014/34/EU, Category 2

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Waste oil collection/extractor-75 l Venturi-mobile specification Compressed air is pumped into the container via the Venturi block a vacuum is created Manometer/vacuum meter for displaying pressure and negative pressure Oil is extracted via the dipstick opening Level indicator Safety pressure relief valve permanently set to 0.5 bar, with throttle valve Plug nipple for Rectus coupling, type 26, NW 7.2 mm (20 062), ball valve Suction hose, 2 m, with spiral spring Suction probes, Ø 5/6/8 mm With adapter for BMW, Mercedes, VW, Audi and Smart Probe holder Transparent dispensing hose, 2 m, with Steel outlet elbow, ball valve Collection funnel with removable sieve and additional coarse sieve Solid push handle 2 fixed wheels, 2 steering wheels Pressure evacuation Container made of 1.5 mm sheet steel With metal apron to protect against damage Painted with oil-resistant hydrostructure varnish With height-adjustable oil collecting funnel For spare parts see Venturi block (04 426)

Request for a quote

IFA TECHNOLOGY GMBH

Germany

As a specialist company according to the German Water Resources Act (WHG), IFA Technology offers expert planning and consulting for the storage of liquids or bulk materials. In the area of so-called LAU plants and systems (plants and systems for storage, filling and handling), our product range includes tank farms and silo systems which, depending on the requirements, consist of mild steel, stainless steel, plastic and GRP tanks. To meet the legal requirements, LAU plants and systems from IFA Technology can be supplied specially coated (HALAR, Teflon, etc.), varnished or painted.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The flow meter with touchscreen display and backlighting impresses with its simple, needs-based display and operability, multilingual interface and compact design. Thanks to the rotating oval wheel meters and the magnets placed on the measuring wheels, it enables precise measurement of the volume flow and measures non-flammable liquids such as paints, varnishes, acids, solvents, alkalis, mineral oils, hydrocarbons and highly flammable liquids precisely, quickly and, above all, efficiently. * Optionally available in an explosion-proof version Features & benefits * Measurement according to the oval gear principle * High measuring accuracy due to overrun correction * Low pressure loss in the system * Touchscreen display with self-explanatory, multilingual user interface * Relay module for volume preselection can be retrofitted at any time * Approved in accordance with ATEX Directive 2014/34/EU, Category 2

Request for a quote

LUTZ PUMPEN GMBH

Germany

The first flow meter with touchscreen display and backlighting impresses with its needs-based display and operability, multilingual interface and compact design. Thanks to the rotating oval wheel meters and the magnets placed on the measuring wheels, it enables precise measurement of the volume flow and measures non-flammable liquids such as paints, varnishes, acids, solvents, alkalis, mineral oils, hydrocarbons and highly flammable liquids precisely, quickly and, above all, efficiently. * Optionally available in explosion-proof design Features & benefits * Measurement according to the oval gear principle * High measuring accuracy due to overrun correction * Low pressure losses in the system * Touchscreen display with self-explanatory, multilingual user interface * Relay module for volume preselection can be retrofitted at any time * Approved in accordance with ATEX Directive 2014/34/EU, Category 2

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The systems of the VEE model series are ideally suited for labelling medium-sized containers such as buckets, paint cans and canisters in all industries such as food, chemicals, paints and varnishes - regardless of whether these are oval, round or rectangular plastic or metal containers. Depending on the customer's requirements, the products can be aligned before the labelling process, and any plastic or metal handles can be brought into the position required for labelling. Optionally, the labelling system can be expanded to include additional labelling stations for applying a lid label, if required.

Request for a quote

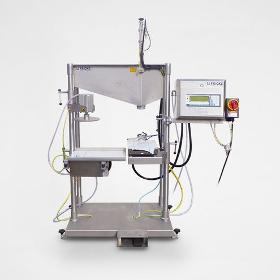

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 12 enables complex control tasks, MES/ERP connections and remote maintenance. Thanks to its modular design, it can be expanded into a fully automatic filling line at any time, including automatic container conveying, capping and labelling. It is suitable for viscous to pasty liquids such as paints and varnishes and offers automatic container transport options as well as an electronic scale. The station supports coarse/fine over-level filling and can be connected directly to storage tanks via inclines or pumps. The system offers you: ■ a calibratable oversize filling system ■ quick cleaning of the valve (the area in contact with the product consists of 3 parts) ■ quick changeover to other container dimensions and changing products ■ Filling, capping and palletising by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Semi-automatic filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. The filling station has the following advantages: ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or inks. For filling open containers, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from intermediate container positioned above the scale with bottom discharge valve using natural drop. The System offers you: ■ calibratable above level filling ■ Thread-cutting, non-dripping filling valve ■ fast cleaning of the container (container and valve are cleaned in approx. 5 min using 1 l of solvent) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 10 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic platform weigher for precise filling of low viscous liquids, e.g.: paints, varnishes, dispersions. For the filling of standard container types, e.g. open cans, buckets and canisters. Above level filling for coarse and fine flow. Product feed from intermediate container positioned above the scale with bottom discharge valve using natural drop. ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the Container (Container and valve can be cleaned in approx. 5 minutes by using 1 litre solvent) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For the filling of open containers, such canisters, open lidded drums or IBCs (Intermediate Bulk Container), directly on the pallet. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibrated above level filling of several containers on one pallet ■ thread-cutting, non-dripping filling valve ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ simple operation by one person ■ Handling of empty containers (lifting heavy loads (filled containers)) not applicable

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For the filling of open containers (min. Ø 150mm opening) just above fill level, e.g. canisters, open lidded drums or IBCs (Intermediate Bulk Container), directly on the pallet. above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above tevel filling just above the fill level with a ride-on valve of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ simple operation by one person ■ handling of empty containers (lifting heavy loads (filled containers)) not applicable ■ automatic height adjustment and automatic change of position

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 50 is a semi-automatic filling machine with over and under level valves for the precise filling of viscous to pasty liquids such as paints, varnishes or adhesives. It is suitable for over-level filling into open containers such as cans and buckets as well as for under-level filling into bunghole containers, e.g. canisters, for foaming, gassing or statically charging liquids. ■ a calibratable over-level filling system ■ Thread-cutting, non-drip filling valve ■ an almost foam-free, calibratable under-level filling system ■ quick cleaning of the valve ■ Quick changeover to other container dimensions and changing products ■ the ideal solution for small and medium-sized filling orders ■ Simple operation by one person ■ Filling capacities of up to 10 containers per minute ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

UV radiation dryers are particularly suitable for UV-hardening paints. Ultraviolet drying process UV drying is a polymerisation process which is triggered by UV light. The process is primarily used for drying flat substrates, wood and furniture paints, overprint varnish on paper, printing inks etc. The process is environmentally compatible and of a particularly high quality. UV paint would never dry without UV light.

Request for a quoteResults for

Paints and varnishes - Import exportNumber of results

45 ProductsCountries

- Germany (45)

- Berlin and region (1)

- Bonn, Düsseldorf and North Rhine and Westphalia (15)

- Frankfurt am Main and Hesse (1)

- Hannover and Lower Saxony (1)

- Magdeburg and Saxony-Anhalt (2)

- Mainz and Rheinland-Pfalz (3)

- Munich, Nuremberg and Bavaria (10)

- Saarbrücken and Saarland (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (9)

- Weimar and Thuringia (2)

Company type

Category

- Bottling and filling - machinery and equipment (13)

- Paints and varnishes (6)

- Pumps (4)

- Goods handling systems, continuous (2)

- Measurement and regulation equipment and instruments - output and flow (2)

- Painting and varnishing of rubber and plastic (1)

- Labelling machines (1)

- Diesel engines (1)

- Inorganic bases and compounds (1)

- Lubricants, industrial (1)

- Petroleum extraction - systems and equipment (1)

- Pipe and tube fittings - ferrous metal (1)

- Protective covers - custom packaging (1)

- Steels and metals - surface treatment and coating (1)

- Vegetable oils (1)