- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packing machines

Results for

Packing machines - Import export

FILLPACK GMBH & CO. KG

Germany

Pail filling machine for 3 – 12 kg 2-lane machine Machine performance: 14 cycles/min. 28 pails/min. 1.680 pails/h Special features: 6 rotary piston filling pumps (4 x coarse dosing, 2 x precise dosing) Precise dosing by means of load cells Film bar with integrated sealing and super-heated steam Pressure cap station with automatic feeder

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

The peel force is a critical parameter for every user of Tape & Reel. If the peel force is too low, the cover tape will not stick on the carrier tape properly and the components may fall out of the pockets. A too high peel force will cause costly down times at the pick & place machines. The KT 5000 peel force tester from KTECH is the ideal tool to measure the peel force on your production floor. For measuring, a strip of the carrier tape is loaded into the KT 5000 and the cover tape is attached to the sensor. The constant movement of the carrier tape is done with a sprocket wheel. The movement speed is controlled with an encoder. The design of the KT 5000 guarantees the same peel angle and the same peel point during the whole measurement. Before each run, the KT 5000 is doing a selfcalibration of the sensor. The measured values are transferred to a PC via a serial RS232 interface. A green bar on the screen shows a good result, if the measurement is out of limit, the bar is red.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the turned parts,which used in motorcycle indusry, after machining, use the vacuum packing prevents oxidation.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 20 form, fill and seal machine enables the production of bags made of polyethylene film from a flat film roll. The film can be neutral or coloured, with continuous printing or centred printing with print mark. The design of the machine and the low loading height allow ergonomic adaptation to a manual feeding station or easy connection to a feeding unit, such as an automatic counter, an automatic weighing system, an automatic assembly machine, an injection moulding machine, a conveyor belt or similar.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 06 form fill and seal machine uses standard polyethylene, biodegradable oxo sleeves or biodegradable sleeves (starch-based). The TEC 06 is particularly suitable for the production of display bags. The sealing head simultaneously performs the top seal of the pouch and the bottom seal of the next pouch, a cut is made between the two welds, and at the same time a pre-cut is made across one thickness of the sleeve to form a "kangaroo pocket" that allows the pouch to be filled. As this pocket is firmly connected to the spool, slippage is not possible, so that the weld seams subsequently run perfectly parallel. Due to the functionality and quality of its equipment, the TEC 06 is a very reliable machine that consumes few wearing parts.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 55 was developed to meet the demand for high throughput rates. Flexibility, easy maintenance, simple settings, synchronisation with the infeed systems, flexibility and quiet operation were the priorities in the development of this machine. The machine achieves an output of up to 80 bags / minute. The most common options and accessories: - Hanger hole - Precutter for easy opening - Jogger to level the products before closing the bag - Bag identification system: - Marking by transfer to the film - Label printer - Inkjet printer - Flap for heavy products - Cell for pre-printed film - Drive by suction belts - Synchronisation with: - Multihead weigher - Auger filler - Cup doser - All other machines - Suction plate for changing the film roll

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Standard elements : - Robust frame in grey or white lacquered steel - Conformator tube - Welding jaw with heating rod (hard chrome plated) with constant temperature controlled by temperature controllers with digital display - Drive of the film by belt - Motorisation of the unwinding of the roll - Control generated by SPS - Touch screen display - Programme memory (weight, length of bags...) - Fine detection of the reel - Translucent mapping Material according to current EC standards. Films that can be used: polypropylene, composite, aluminium, barrier, polyethylene.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Tecnimodern's slanted or vertical form fill and seal machines with very low loading height allow the production of polyethylene or polypropylene film bags from a flat film roll. The film can be neutral or coloured, with continuous printing or centred with print mark. These TEC30 packaging machines have the advantage that they can be equipped with either a thermal sealing system for heat-sealed films or an impulse sealing system for polyethylene films, depending on requirements. To meet the need for all types of packaging, feeding and product shapes, we offer various automatic feeding systems, such as: - Counting with vibrating or centrifugal trays - Weighing with linear scales - Dosing by augers or volumetric feeders

Request for a quote

GEBR. DÜRRBECK KUNSTSTOFFE GMBH

Germany

Plastic film for automatic packing machines is primarily used for the following: E-commerce: as rolls for despatch packaging where the product is automatically wrapped in film, as new packaging for returned goods, etc. Pharmaceutical industry: for bundling and thereby securing the shipment of multiple packages Sanitary products: for packaging paper towels and tissues, nappies and other sanitary items Insulation industry: for packaging insulation boards using stretch packing machines Food industry: food packaging machines (frozen foods, fruit, vegetables, etc.)

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

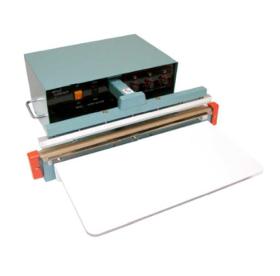

Electromagnetic sealing jaw type MS...IP for welding and sealing bags: - From PE - From PP - From soft PVC or polyamide Features: This sealing jaw has: - Adjustable welding time - Adjustable cooling time - Adjustable cycle time The jaw is controlled by an electric foot pedal.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Continuous sealers type SCV and SCH, to seal bags made of PE, PP, soft PVC, polyamide paper, aluminium or cardboard tabs as they pass through the sealer. - Adjustable speed from 0 to 12 m/minute - Temperature adjustable from 0°C to 400°C. - Width of the weld: 10 mm - Maximum weight on conveyor belt: 10 kg - Optional: bag counter - hot stamping on the weld seam

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Thermosealing jaw type MS... for hermetic sealing of bags made of aluminium, PP or with cardboard tab. Width of the seal 10 mm ribbed.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

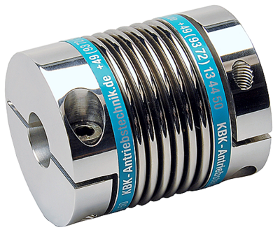

Metal Bellows Coupling with split hubs Backlash-free metal bellows coupling with split hubs For shaft diameters from 10 – 80 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Radial assembly! Due to the split hub design shafts can be mounted and adjusted before the assembly of the coupling Perfect bellows coupling for servo drives, e.g. in testing equipment, automation techniques, packing machines Torque range: 18 – 1400 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling with collet clamps, compact Backlash-free metal bellows coupling with compact clamp hubs For shaft diameters from 10 – 70 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Perfect bellows coupling for connecting servo motors, e.g. in machine tools, automation techniques, packing machines, wood working machines Torque range: 18 – 1400 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

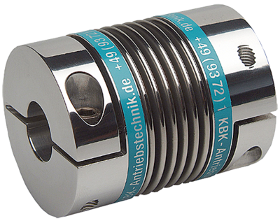

Metal Bellows Coupling with collet clamps / Hub material: aluminum Backlash-free metal bellows coupling with clamp hubs Hub material: aluminum Alternatively to steel executions we recommend our series KB4AL from size 80 - 500 For shaft diameters from 10 – 70 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Easy assembly and low inertia Perfect bellows coupling for connecting servo motors, e.g. in machine tools, automation techniques, packing machines, wood working machines Torque range: 18 – 500 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling with collet clamps Backlash-free metal bellows coupling with clamp hubs Hub material: up to 60Nm – aluminum, up from 80Nm - steel For shaft diameters from 10 – 80 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Easy to assemble Perfect bellows coupling for connecting servo motors, e.g. in machine tools, automation techniques, packing machines, wood working machines Torque range: 18 – 1400 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Miniature Metal Bellows Coupling with split hubs Backlash-free miniature metal bellows coupling with split hubs For shaft diameters from 3 – 25 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Radial assembly! Due to the split hub design shafts can be mounted and adjusted before the assembly of the coupling Perfect bellows coupling for servo drives, e.g. in testing equipment, automation techniques, packing machines, Torque range: 0,5 – 10 Nm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HBP1100 - HBP1500 / HBP1100A - HBP1500A are series of semi-automatic and automatic large bandsaws manufactured by Behringer. The large-scale universal machines from BEHRINGER can handle any job that is needed. Their expertise: Handling heavy-duty workpieces with ease and slicing through the material with extreme cutting performance. When processing long solid workpieces – rolled or rough turned – or processing large pipes, these benefits make for dramatic improvements in productivity. Round or rectangular – the results are equally impressive. In the BEHRINGER semi-automatic models, the material is positioned by eye, for instance with the aid of a line laser. For longer cut piece lengths, we recommend using a measuring device for precise positioning. The use of a feed gripper allows automatic sawing of solid material or pipes.

Request for a quote

EXCOR KORROSIONSSCHUTZ-TECHNOLOGIEN UND -PRODUKTE GMBH

Germany

EXCOR VALENO Skin Film adheres to the packed product as tightly as a second skin and retains the product on the so-called skinboard. VCI skin packages are particularly suitable for protecting small items and replacement parts from mechanical and corrosive damage. In practical applications it is advisable to combine EXCOR VALENO Skin Film with EXCOR ABRIGO Skinboard because fibre boards with no corrosion protection can induce corrosion if they come into direct contact with metal surfaces. All EXCOR VALENO Skin Films are suitable for use in packing machines.

Request for a quote

OPTIMA LIFE SCIENCE GMBH

Germany

ADVANTAGES Printing: In-line flexographic printing of wallet Compliance: Complies with the industry standards of sterility Flexibility: Processes crepe and hard kraft walleting materials Validation: Fully validated, GMP, CE and OSHA compliant Optional AGPM unit, an online cuffing system that automatically handles glove placement. A link to a platen sealer for outer pouching is possible. PROCESSES Auto-Glove Placement: Automatic or manuel placement of the gloves onto the packaging web Packaging: The wallets are cut off, tucked and folded Transfer of the finished wallets to a packaging table or packaging machine - ideal: HDW Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems.

ACTIVE ANTS

Germany

Our packing machines are automatic and pack orders of various sizes. If your package does not fit in the machine, one of our knowledgeable staff will gladly pack your package by hand.

Request for a quoteResults for

Packing machines - Import exportNumber of results

22 ProductsCountries

Category

- Custom packaging (8)

- Measurement and control instruments (6)

- Packing and packaging - machinery and equipment (2)

- Films for packaging (1)

- Anti-corrosion products, chemical (1)

- Motorcycle parts and accessories (1)

- Rolling mills - machinery and installations (1)

- Sawing machine tools (1)

- Warehouse logistics (1)