- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packaging machines for packing

Results for

Packaging machines for packing - Import export

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 55 was developed to meet the demand for high throughput rates. Flexibility, easy maintenance, simple settings, synchronisation with the infeed systems, flexibility and quiet operation were the priorities in the development of this machine. The machine achieves an output of up to 80 bags / minute. The most common options and accessories: - Hanger hole - Precutter for easy opening - Jogger to level the products before closing the bag - Bag identification system: - Marking by transfer to the film - Label printer - Inkjet printer - Flap for heavy products - Cell for pre-printed film - Drive by suction belts - Synchronisation with: - Multihead weigher - Auger filler - Cup doser - All other machines - Suction plate for changing the film roll

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Standard elements : - Robust frame in grey or white lacquered steel - Conformator tube - Welding jaw with heating rod (hard chrome plated) with constant temperature controlled by temperature controllers with digital display - Drive of the film by belt - Motorisation of the unwinding of the roll - Control generated by SPS - Touch screen display - Programme memory (weight, length of bags...) - Fine detection of the reel - Translucent mapping Material according to current EC standards. Films that can be used: polypropylene, composite, aluminium, barrier, polyethylene.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 06 form fill and seal machine uses standard polyethylene, biodegradable oxo sleeves or biodegradable sleeves (starch-based). The TEC 06 is particularly suitable for the production of display bags. The sealing head simultaneously performs the top seal of the pouch and the bottom seal of the next pouch, a cut is made between the two welds, and at the same time a pre-cut is made across one thickness of the sleeve to form a "kangaroo pocket" that allows the pouch to be filled. As this pocket is firmly connected to the spool, slippage is not possible, so that the weld seams subsequently run perfectly parallel. Due to the functionality and quality of its equipment, the TEC 06 is a very reliable machine that consumes few wearing parts.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

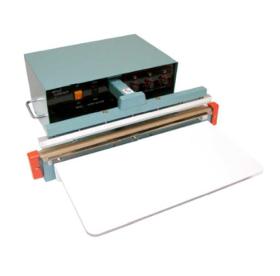

Thermosealing jaw type MS... for hermetic sealing of bags made of aluminium, PP or with cardboard tab. Width of the seal 10 mm ribbed.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Electromagnetic sealing jaw type MS...IP for welding and sealing bags: - From PE - From PP - From soft PVC or polyamide Features: This sealing jaw has: - Adjustable welding time - Adjustable cooling time - Adjustable cycle time The jaw is controlled by an electric foot pedal.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

The vacuum packgaing machine AZ450ES from AIRZERO is working with a suction nozzle compared to vacuum chamber machines. The main advantages are Since only the bag and not the entire chamber is emptied, the process is faster. Lower gas consumption when gassing (only the bag is gassed and not the entire chamber). The gas is blown into the bag in a targeted and controlled manner. No limitation of the bag length by the chamber. Bar goods can therefore also be processed. Compact standalone device. double sealing (up/down) ejektorvakuum pump (air pressure required) gas flushing vacuum creation timer controlled, sensor controlled digital vakuum display 4 programms can be saved housing of stainless steel suitable for cleanroom

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

The peel force is a critical parameter for every user of Tape & Reel. If the peel force is too low, the cover tape will not stick on the carrier tape properly and the components may fall out of the pockets. A too high peel force will cause costly down times at the pick & place machines. The KT 5000 peel force tester from KTECH is the ideal tool to measure the peel force on your production floor. For measuring, a strip of the carrier tape is loaded into the KT 5000 and the cover tape is attached to the sensor. The constant movement of the carrier tape is done with a sprocket wheel. The movement speed is controlled with an encoder. The design of the KT 5000 guarantees the same peel angle and the same peel point during the whole measurement. Before each run, the KT 5000 is doing a selfcalibration of the sensor. The measured values are transferred to a PC via a serial RS232 interface. A green bar on the screen shows a good result, if the measurement is out of limit, the bar is red.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

In contrast to chamber devices, the vacuum sealer AZ450 from AIRZERO works with a suction nozzle. This principle offers advantages Since only the bag and not the entire chamber is emptied, the process is faster. Lower gas consumption when gassing (only the bag is gassed and not the entire chamber). The gas is blown into the bag in a targeted and controlled manner. No limitation of the bag length by the chamber. Bar goods can therefore also be processed. Compact desktop device. double sealing (up/down) ejektor vakuum pump (air pressure required) gas flushing digital vakuum display 4 programms can be saved housing of stainless steel

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Filling - Filling systems coordinated to the product - Freely programmable filling nozzle movement and filling speed for below/over or bottom-up filling Containers - Container classification using a portioning device - Container transport using pucks for flexible production and fast conversion - Container transport without pucks possible - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport - Very gentle processing of the containers - Processing different container shapes Design - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Running direction of the machine from left to right - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system

OPTIMA CONSUMER GMBH

Germany

Containers - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification using a rotary feeder - Container transport using pucks for flexible production and fast conversion - Container transport without pucks possible - Cycled container transport - Very gentle processing of the containers - Processing different container shapes Shapes -User-friendly, fast and primarily tool-free format change Design - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Secure and sturdy mechanical system Drive - Drive via wear-free servomotors Manufacture/Closing - Positioning the caps manually for semi-automatic processes - Closing systems coordinated to the product

Results for

Packaging machines for packing - Import exportNumber of results

11 ProductsCountries

Company type