- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- online monitoring

Results for

Online monitoring - Import export

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

2-component dosing solution with optimum installation space design cascadable multiple dosing system with small dosing head distances minimum space requirement in automation systems. The ViscoDuo-P 4/4 2-component dispenser is a valveless, static, space-saving mixing head with dispensers arranged directly in front of the mixer. The EC version dispensers have been specially designed for easy cleaning (Easy-Clean) and checking of the pump interior. No valves are required in the mixing head. The components to be mixed are metered into the static mixing tube purely volumetrically via the dispenser without dead space. Your advantages: - Processing of viscous materials, unfilled as well as very highly filled supply of the medium with only low inlet pressure - Setting the desired mixing ratio by adjusting the speed ratio of the two dispensers - sensors integrated without dead space in each component for online process monitoring - Withdrawal possible

Request for a quote

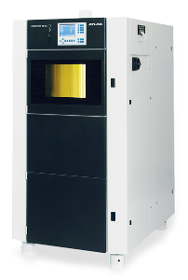

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Xenotest Beta+ is a premium stand-alone rotating rack xenon instrument with 4000cm 2 exposure area. It comes serially with a complete set of parameter controls. Irradiance and temperature are measured and controlled directly on the sample level using on-rack XENOSENSIV sensor technology. Beta+ complies with the vast majority of industry standards. Due to its large test chamber and highly reliable performance, it’s ideal for larger capacities or sample sizes. 3x 2200 W air-cooled Xenon Lamps 4000 cm 2 exposure area High-irradiance testing up to 120 W/m 2 (2 Sun) Touch screen with colour display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400 nm) Direct Setting and Control of Black Standard Temperature Direct Setting and Control of Chamber Temperature Direct Setting and Control of Relative Humidity Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test methods Multilingual User Interface Non-aging XENOCHROME filters to simulate outdoor daylight, daylight behind window On-rack XENOSENSIV 300-400 nm for measuring and controlling irradiance (in W/m 2) and BST (C°) on sample level Selectable Temperature control either by Chamber Temperature (max. 70 °C) or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 130 °C) Fan-controlled temperature difference between Chamber and Black Standard Temperature Ultrasonic humidification system for humidity control Specimen spray system with integrated 60 l water reservoir Outer cylinder made of Special UV glass Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via memory card or RS 232 interface Ethernet interface for connection to internal computer network and use of XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Thermoprinter XenoCal WST White Standard Thermometer XenoCal BST Black Standard Thermometer Rack spray system XenoCal BB 300-400 Irradiance Sensor XenoCal WB 300-800 Irradiance Sensor XenoCal NB 340 Irradiance Sensor

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Xenotest Beta+ FD is a premium stand-alone rotating rack xenon instrument with 4000cm2 exposure area. It’s completely target designed to meet the testing needs of the FMCG industry, such as drinks, foodstuffs, personal care or household products. Beta+ FD enables consumer goods manufacturers to test their products realistically within very short test times, typically with acceleration factors between 10-50 versus real time. It’s for reliable qualification of stable product formulations, determination of appropriate packaging materials, and supporting product shelflife claims. Beta+ FD offers two custom racks - a bottle rack and a packagings rack. Both carry loads up to 20 kg and fit various packaging shapes and sizes. Economic non-aging filters guarantee realistic simulation of all three common light conditions - outdoor Daylight / indoor Daylight / Supermarket light, while a chiller keeps test temperatures on realistic levels even at high irradiance. Programming and monitoring can be done online. 3x 2200 W air-cooled Xenon Lamps 4000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Direct setting and control of Irradiance (300-400 nm) or (300-800 nm) Direct Setting and Control of Black Standard Temperature (BST) Direct Setting and Control of Chamber Temperature (CHT) Display of Diagnostic Messages Storage for 10 user-defined test methods Multilingual User Interface Test chamber with rotating rack technology; for application-specific specimen racks Thermal insulation of test chamber and periphery preventing water condensation Non-aging XENOCHROME filters to simulate outdoor daylight, daylight behind window Optional StoreLight filter to simulate supermarket light conditions On-rack XENOSENSIV 300-400 nm or 300-800 nm sensor for measuring and controlling irradiance (in W/m²) and BST (C°) on sample level Selectable Temperature control either by CHT (10° *- 70°C; *with chiller) or by CHT and BST (25° * - 120°C) simultaneously (dual control) Fan-controlled temperature difference between Chamber and Black Standard Temperature Chiller SunCool Beta+ for extended CHT- and BST-ranges towards lower temperatures UV-protected test chamber window Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Internal memory chip for storing instrument data Data output via memory card or RS 232 interface Ethernet interface for connection to internal computer network and use of XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“)

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The 220 is a large capacity lightfastness tester dedicated for textile testing. It comes with premium on-rack light and temperature sensor and non-aging optical filter technology. With the ability to test 38 samples, the 220 provides nearly twice as much capacity in the same footprint compared to 150S+. The combination of its large test chamber and the efficient use of power and water make it today’s most economic air-cooled instrument available. It complies to standards ISO 105 B02, AATCC TM16 (option 3), and Marks & Spencer C9, C9A. 1x 2200 W air-cooled Xenon Lamp 2310 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400 nm) Direct Setting and Control of Black Standard Temperature Direct Setting and Control of Chamber Temperature Direct Setting and Control of Relative Humidity Display of Diagnostic Message Storage for 10 user-defined tests Multilingual User Interface Non-aging filter systems for ISO 105-B02 and AATCC TM16 On-rack XENOSENSIV® for measuring and controlling irradiance (in W/m²) and Black Standard Temperature on sample level Selectable temperature control either by Chamber Temperature (up to 65 °C) or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 100 °C) simultaneously Fan-controlled temperature difference between Chamber and Black Standard Temperature Ultrasonic humidification system with integrated 60l water reservoir for humidity control (automatic refill) Sample rack suiting 19 sample holders with capacity for 38 standard textile samples Pre-programmed standards ISO 105 B02 and AATCC TM16-2004 (Option 3) Switch-off by radiant exposure, light exposure or total operating time UV-protected test chamber window Advanced Auto Start functions Internal memory chip for storing instrument data Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) XenoCal BB 300-400 XenoCal BB 300-400 BST XenoCal BST

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XLS+ is an with state-of-the-art UV-control for reliable R&D screening tests. The benchtop design fits into every lab while optional accessories – water spray, immersion, refrigeration – expand the testing capabilities and offer easy ways to customize it to your needs. It comes standard with a 1100 cm 2 exposure area, suiting multiple flat or 3D samples. 1x 1700 W air-cooled Xenon Lamps 1100 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and Control of Irradiance in the wavelength range 300-800 nm / Lux; or 300-400 nm / 340 nm Measurement and Control of Black Standard Temperature (BST); BPT optional Measurement of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Bench-top design 90 x 54 x 62 cm Static, horizontal exposure area for flat or 3D specimen Temperature control of BST in the range 45-100 °C; BPT 45-95 °C Fan-controlled temperature difference between Chamber Temperature and BST Light cassette including non-ageing aluminium reflector, uncoated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Irradiance control wide band 300 – 800 nm (Lux) or narrow band 300 – 400 nm BST/BPT exchange kit

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XXL+ FD is a large state-of-the-art xenon flatbed instrument. It’s completely target designed to meet the testing needs of the FMCG industry, such as drinks, foodstuffs, personal care or household products. XXL+ FD enables consumer goods manufacturers to test their products realistically within very short test times, typically with acceleration factors between 10-30 versus real time. It’s for reliable qualification of stable product formulations, determination of appropriate packaging materials, and supporting product shelflife claims. 3x 1700 W air-cooled Xenon Lamps 3000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and Control of Irradiance 300-400 nm / 340nm or 420nm Measurement and Control of Black Standard (BST); (Black Panel optional) Measurement and Control of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Thermal insulation of test chamber and periphery preventing water condensation Temperature control selectable either via CHT (15° * - 70 °C; *with chiller) or via CHT and BST (25° * - 100 °C; *with chiller) simultaneously (dual control) Adapted chiller SunCool XXL+ for testing at low temperatures in the range 15-30°C CHT; detachable for standard weathering testing needs Ultrasonic humidification system for controlled humidity during operation without SunCool Specimen spray system with integrated 60 l water reservoir for spray cycles at 25°C ** - 70°C Static, horizontal exposure area for flat or 3D specimen Test chamber with 5 ° slope for optimum spray water drain Access port ca. 3,0 x 2,5 cm for potential use of additional external sensors inside the test chamber Light cassette including non-ageing aluminium reflector, coated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Sliding sample table for easy specimen loading; exposure area (WxD) 74 x 37 cm

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XXL+ is a large state-of-the-art xenon flatbed instrument. The 3000 cm2 test chamber is perfect for high volume weathering testing of large flat or 3-D specimen. SUNTEST XXL+ offers a complete set of features ideal for standard testing covering all common industry weathering standards. 3x 1700 W air-cooled Xenon Lamps 3000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and control of Irradiance 300-400 nm / 340nm or 420nm Measurement and control of Black Standard (BST); (Black Panel optional) Measurement and control of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Ultrasonic humidification system for humidity control Specimen spray system with integrated 60 l water reservoir Static, horizontal exposure area for flat or 3D specimen Test chamber with 5 ° slope for optimum spray water drain Access port ca. 3,0 x 2,5 cm for potential use of additional external sensors inside the test chamber Light cassette including non-ageing aluminium reflector, coated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Various specimen holders to hold different panel sizes. XenoCal sensors to calibrate BST and irradiance. Large variety of filter systems: coated and uncoated quartz, special UV glass, daylight filter, window glass, Solar ID 65, Solar Standard, to meet various spectral specifications in standards.

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

Xenotest Alpha+ is a compact stand-alone rotating rack xenon instrument with 1320cm 2 exposure area. It comes serially with a complete set of parameter controls. Irradiance and temperature are measured and controlled directly on the sample level using on-rack XENOSENSIV sensor technology. Alpha+ complies with the vast majority of industry standards setting the benchmark in narrow tolerance testing. Due to its highly reliable performance, it’s often chosen by R&D departments or commercial Service Test Houses. 1x 2200 W air-cooled Xenon Lamp 1320 cm 2 exposure area High-irradiance testing up to 180 W/m 2 (3 Sun) Touch screen with colour display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400nm) Direct Setting and Control of Black Standard Temperature Direct Setting and Control of Chamber Temperature Direct Setting and Control of Relative Humidity Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test methods Multilingual User Interface Non-aging XENOCHROME filters to simulate outdoor daylight, daylight behind window glass On-rack XENOSENSIV 300-400 nm for measuring and controlling irradiance (in W/m²) and BST (C°) on sample level Selectable Temperature control either by Chamber Temperature (max. 70 °C), or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 130 °C) Fan-controlled temperature difference between Chamber and Black Standard Temperature Ultrasonic humidification system for humidity control Specimen spray system with integrated 60 l water reservoir Specimen holder carousel for 11 specimen holders Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Thermoprinter XenoCal BST Black Standard Thermometer XenoCal WST White Standard Thermometer XenoCal BB 300-400 Irradiance Sensor XenoCal WB 300-800 Irradiance Sensor XenoCal NB 340 Irradiance Sensor Turning mode programmable

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoDuo-VM 2-component dispenser is a valveless dosing system for static mixing based on the proven progressive cavity technology and thanks to its purely volumetric precise dosing principle, is ideally suited for high-precision dosing tasks. Built according to modular structure, a configuration of the 2-component dosing systems as well as maintenance and part exchange at module level is possible. The material components are mixed downstream of the mixing head only in the mixing tube to prevent material hardening in the system components of the mixing head. Your advantages: - repeatable dosing volume even with viscosity and density fluctuations - Processing of low to high viscosity materials with low to very high filler content - Dispenser and mixing head segments can be combined in size due to modularity - standard equipment with dead space-free integrated dosing pressure sensors for online process monitoring - simple assembly/disassembly of the components

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Xenotest 440 is a highly versatile xenon weathering instrument for a variety of materials. Designed for fast and economical testing, the Xenotest 440 utilizes XenoLogic™, a revolutionary new twin-lamp operating technology which enables high irradiance levels of 120 W/m 2 of total UV radiation. In addition, XenoLogic provides extended lamp service life. With this new technology, the two xenon lamps combined can last over 4000 hours under standard testing levels of 40-60 W/m 2. 2 x 2200W air-cooled xenon lamps 2310 cm 2 exposure area XenoLogic TM lamp operating technology for extended lamp service life Touch screen with color display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400 nm) Direct Setting and Control of Black Standard Temperature (BST) Direct Setting and Control of Chamber Temperature (CHT) Direct Setting and Control of Relative Humidity Display of Diagnostic Messages Storage for 10 user-defined tests Multi-Language Capability: English, German, Italian, French, Spanish, Turkish, Dutch, Polish, Hungarian, Czech, Japanese, Korean, Chinese On-rack XENOSENSIV® RC-34 BST for measuring and controlling irradiance (in W/m²) in the wavelength range 300-400 nm and BST (°C) on specimen level Selectable temperature control either by Chamber Temperature (up to 65 °C) or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 115 °C) simultaneously Fan-controlled temperature difference between BST and CHT Ultrasonic humidifier controlling relative humidity in the range 10-75% (Light cycle) Integrated 60 litre water reservoir for humidity control and specimen spray (automatic refill) Specimen spray system Rotating specimen rack with 38 test positions (13.5 cm x 4.5 cm); 33 (10.0 cm x 6.8 cm); 22 (13.5 cm x 5.5 cm); 11 (29.5 cm x 7.0 cm) Pre-programmed lightfastness and weathering standards Outer cylinder made of special UV glass UV-protected test chamber window Internal memory chip for storing instrument data Data output via Memory Card or serial interface RS232 Ethernet interface for XenoTouch Add-ons (Remote Control, E-Mail Service, Online Monitoring) XENOSENSIV RC-420 BPT

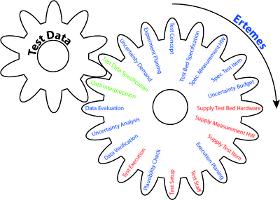

ERTEMES GMBH

Germany

We will help you with your experiment. Whether you need classic personnel support to complete the test crew or need support for specific test tasks: We can help you with: Assumption of certain functions, e.g. test engineer or measurement technician; Assumption of certain tasks, e.g. online monitoring, or daily data validation; Provision of additional measurement technology. Do you still need some resources for your test? We will find the right solution for you: Testbed; Instrumentation; Ancillary systems (e.g. cooling units or heaters); Test Specimen / Test Vehicle; Test Personnel.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

From the project planning stage through to the end of their operating life we offer a range of concepts for economical and fault-free operation of your machines Target-oriented maintenance intervals to match the respective operating conditions Online and offline status monitoring Trend measurements relating to wear behaviour of the mechanical and electrical components Stocking spare parts for shorter downtimes Training for maintenance staff 24 hour service Company-oriented maintenance contracts Modernisation of the machine, controllers and protection equipment Environmentally compatible recyclingTesting of electrical machines and systems, type tests, system tests, heat run tests according to DIN standards Dynamic balancing or rotors Cleaning and oven drying of large machine parts such as stators or rotors VPI impregnation with rotating hardening process in drying oven VPI impregnation of transformers and large coils VPI or resin-rich coil production Manufacture of tooth-wound coils

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

The Fluke 3563 combines a highfrequency piezoelectric sensor and insightful software analytics, enabling maintenance teams to regularly monitor and analyze vibration readings for a facility’s productioncritical assets. Its smart battery management lets maintenance pros determine the data transmission rate and adapt and extend the sensor battery’s life while still getting the data required. The sensor’s LIVEAsset Portal software application includes customizable frequency band measurements, automatically generated thresholds based on asset details, trend visualization, and frequency identification graphs. These views enable users to determine which fault is causing a problem to an asset and the cause of the fault. With this analysis, users can evaluate critical nextstep actions to take. The result is extended peak operating performance and more efficient maintenance team use – delivering increased business value from maintenance operations.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

With VIBRONET Signalmaster, up to 162 measuring points can be installed and entire production areas can be included in the monitoring. The distance between the basic unit and the sensor does not play a decisive role, because the wiring concept used reduces installation costs to a minimum. VIBRONET Signalmaster is therefore one of the most efficient and costeffective monitoring systems for large machinery and extensive plants with productioncritical units. Vibration, temperature, RPM and other process parameters can be integrated into a monitoring network that covers whole plant sections.The robust cabling installation guarantees reliable machine monitoring even in harsh environments such as cement plants, openpit and underground mining or refineries. VIBRONET Signalmaster is easily expandable. The data recorded can be analyzed in OMNITREND CENTER, the universal software platform for PRUFTECHNIK's Condition Monitoring systems.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

OMNITREND Asset View is a serverbased visualization software with a simple and clearly structured user interface and ideal for managers and machine operators. The software supports all PRUFTECHNIK online condition monitoring systems including VIBGUARD IIoT (20 and 16 channels), VIBGUARD compact, and VIBRONET Signalmaster. All that is needed to obtain realtime data via the server is an uptodate browser as well as a user name and a password. OMNITREND Asset View communicates via the modern IIoT interface MQTT for worldwide access and remote overview. The user interface features a clearly structured design. A traffic light function gives a quick overview of the current condition of the monitored assets. Threshold violations can be acknowledged.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

VIBGUARD compact for individual assets VIBGUARD compact offers six measuring channels for continuous monitoring. It is perfectly suited for fast and highly dynamic equipment. In particular, the VIBGUARD compact meets the requirements of critical assets that are characterized by high availability, high aggregate values, complex drives and changing operating conditions. Whether preinstalled in an IP65 compact housing or as a switch cabinet system module, the VIBGUARD compact is perfect for diagnostic condition monitoring of individual extruders, large fans, multiphase or vacuum pumps, turbocompressors, mill stands, or centrifuges. All six measuring channels are designed as highly dynamic analog input channels and can be equipped with either standard ICP vibration sensors or with voltage input signals for process variables.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

VIBGUARD IIoT offers a choice of 12, 16 or 20 measuring channels which are sampled in parallel and synchronously. This allows even the most complex equipment to be continuously monitored and protected against unplanned shutdowns. VIBGUARD IIoT works autonomously and performs the measurement tasks automatically. The measurement data such as time signal, characteristic value, FFT spectrum, kinetic wave path (orbits), or torque are processed in parallel and almost in real time and can be correlated with the running production process. The fast data processing makes VIBGUARD IIoT the perfect monitoring and diagnostic system for systems with short operating cycles, such as cranes, machine tools, presses, or for machines with highly dynamic processes, such as test benches, wind turbines or chain conveyors. All critical fans and pumps can also be monitored easily but effectively with VIBGUARD IIoT.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BLUESENS GAS SENSOR GMBH

Germany

BlueVary is a maintenance free gas analyzer for variable biotechnological applications. By selectable sensor cartridges different measuring tasks ranging from microbial, cell culture to monitoring of algae and biogas processes can be covered by just one device. The analyzer consists of a basis element with measurement places for two of the variable sensor cartridges. The third place holds a cartridge to compensate pressure and/or humidity. The integrated display ensures an overview about sensor and concentrations at any time. As already known from the forerunner analyzers BlueVary can be mounted on each fermenter from lab to production scale by using different mechanical connections without being limited by fermenter brand or manufacturer. Various data outputs are available. Annual maintenance is not necessary. In combination with the open software BlueVis the BlueVary turns into a versatile, effective tool for real-time online monitoring and optimization of bioprocesses of any kind.

Request for a quote

SOLARSPRING GMBH MEMBRANE SOLUTIONS

Germany

"Clean water with clean electricity Billions of people still have no access to clean drinking water or lack adequate sanitation. Residents of rural areas are particularly affected. If drinkable water is needed far away from any infrastructure, SolarPurification can help. The system can produce up to 200,000 litres of clean drinking water per day even from heavily polluted surface and ground water. Clean drinking water without chemicals Several treatment stages make it possible that the drinking water is not only clean but also safe. The SolarPurification filters 99.999 % of all bacteria and viruses from the existing water - and this completely without the use of chemicals. This is made possible by a combination of ultrafiltration, activated carbon filtration and UV disinfection. High-quality components, automatic operation with PLC and online monitoring characterize this compact water treatment system. Low maintenance and solar powered

Request for a quoteResults for

Online monitoring - Import exportNumber of results

20 ProductsCountries

Company type

Category