- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- oil and gas industry

Results for

Oil and gas industry - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flanges are a crucial component in various piping systems, providing ease of assembly and strength in connecting pipes, valves, pumps, and other equipment. They serve as a plate for covering or closing the end of a pipe and are commonly used in plumbing, oil and gas, petrochemical, and food industries due to their durability and corrosion resistance. Types and Specifications Stainless steel flanges come in several types to suit different applications: Weld Neck Flanges: Designed to be welded to the pipe. Suitable for high-pressure applications. Slip-On Flanges: Easily slide over the pipe and are welded in place. Socket Weld Flanges: Used for smaller, high-pressure piping. Threaded Flanges: Attached without welding, ideal for low-pressure applications or pipes with a thin wall. Blind Flanges: Used to seal the end of piping systems or pressure vessel openings. Lap Joint Flanges: Used with stub end fittings for applications requiring frequent dismantling.

Request for a quote

AAAGILER GMBH

Germany

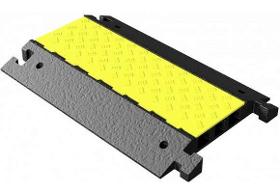

Drive-over heavy-duty cable bridge as drive-over protection for cables and hoses in outdoor areas. Ideal for use on construction sites, in the oil and gas industry, in mining as well as in the military and suitable for heavy trucks and forklifts Up to 20 t max load Easy to assemble, disassemble and store With 3 channels Highly visible

Request for a quote

WOMA GMBH

Germany

With operating pressures of up to 1,000 bar, the Yseries pumps are ideally suited to a wide variety of cleaning work, e.g. in the chemical industry, oil and gas industries as well as in the area of ship cleaning. Due to the small size and low weight, they can be easily installed in unit with very small base frames.

Request for a quote

CINCHSEAL EUROPE GMBH

Germany

The spiral-wound gasket is the ideal gasket for applications with high pressure and temperature requirements. Used in pipelines and apparatus in the chemical, petrochemical, oil and gas production and transport industries, as well as in valves and pumps. Due to the V-shape of the metallic winding strip, the spiral-wound gasket is the only gasket with appreciable recovery, even after long periods of operation.

Request for a quote

ANTHERMO GMBH

Germany

Swept outlet similar to ANSI B 16.19 / ANSI B 36.10 Swept outlets in pipeline construction A swept outlet is used in pipeline construction just like a welding outlet, a socket welded outlet or a threaded outlet for a 90 ° branch. A swept outlet is an alternative to the T-piece / red. In comparison to the T-piece / Red.Tee, the installation effort for a swept outlet is lower because only one hole has to be drilled into a pipe. The swept outlet can then be welded into this hole. A swept outlet differs from a welding outlet in the type of welding. While a welding outlet is only placed on the run pipe and then welded, a swept outlet is welded directly into the run pipe. Ideal stress distribution Swept outlets were developed in order to achieve the best possible stress distribution for internal pressure and pipe forces. Due to the favorable voltage level, swept outlets are often used in highly stressed pipes in the oil and gas industry.

Request for a quote

SPIROL

Germany

SPIROL manufactures Coiled Spring Pins out of 316 stainless steel to meet specific application requirements. Type 316 stainless steel is similar to 302/304 stainless steel with a slightly higher nickel content and the addition of molybdenum. The molybdenum content increases the chemical resistance of this alloy greatly. 316 exhibits superior pitting resistance against sea water, acetic acid vapors, chlorides, sodium and calcium brines, hypochlorite solutions, phosphoric acid, and the sulfite liquors and sulfurous acids used in the paper and pulp industry. This alloy is also austenitic, non-magnetic and non-hardenable using conventional methods. 316 stainless steel has better mechanical properties at elevated temperatures than 302/304 and offers excellent mechanical integrity at subzero temperatures. Typical applications for SPIROL's 316 Stainless Steel Coiled Pins include the following: marine, processing equipment, industrial, oil and gas and medical.

Request for a quote

AIS HENSCH AUTOMATION-INDUSTRY- SOLUTIONS INH. IGOR HENSCH

Germany

The industrial CPUs from AIS Hensch Automation-Industry-Solution represent a first-class solution for controlling automated production processes in various industrial sectors. These CPUs are characterized by their technological excellence, reliability and versatility, making them an indispensable component for optimizing manufacturing processes. Thanks to their powerful processing, our industrial CPUs offer precise control that can be seamlessly integrated into a wide variety of production environments. From the oil and gas industry to mechanical engineering, these CPUs flexibly adapt to the specific requirements of different industries. The robustness and longevity of our industrial CPUs ensure reliable performance even under demanding conditions.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

For liquids in basic process applications The OPTIWAVE 5400 is a 2-wire 24 GHz radar (FMCW) level transmitter for liquids in basic process applications. It is particularly designed for continuous, non-contact level measurement in the chemical, petrochemical as well as oil and gas industry. It can be equipped with a PP Drop antenna for condensing atmospheres and corrosive media but features also Metallic Horn antennas. Due to its high dynamic range, the 24 GHz radar can measure distances up to 100 m / 328 ft.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Radar (FMCW) level transmitter for agitated and corrosive liquids The OPTIWAVE 7400 is a 2-wire 24 GHz radar (FMCW) level transmitter for liquids in harsh environments like tanks with agitators containing corrosive media. It is particularly designed for continuous, non-contact level measurement under extreme conditions prevalent in the chemical, petrochemical or oil and gas industry. The device features Metallic Horn antennas as well as PTFE and PEEK Drop antennas for measuring distances up to 100 m / 328 ft. The Drop antennas are perfectly suited for aggressive liquids in tanks. In applications with toxic and dangerous products, this radar device can be equipped with a Metaglas® second sealing barrier.

Request for a quote

JACOB GMBH

Germany

Safety, reliability and ease of maintenance are the most important requirements for lighting systems when used in harsh and potentially explosive environments. Lighting that is characterized by a long and maintenance-free service life, low energy consumption, durability and high quality light is ideal. The Protecta X LED meets all of these requirements. It is therefore no longer only used in applications in the oil and gas industry, but increasingly in offshore wind farms, e.g. on HVDC converter platforms. Power 16 W up to 38 W Delivered output 2.696 lm – 7.474 lm Colour Temperature 5000 K (Cool White, 4000 K available as option) Temperature -40 °C / +60 °C and -25 °C / +60 °C = Emergency version Enclosure Marine grade aluminium body with polycarbonate diffuser Live Plug-and-Play-Battery-Stick Protection grade IP66 / IP67 Marking Ex e mb q IIC T4 Gb, Ex tb IIIC T95 °C Db IP6X Area classification Zone 1 and 21

Request for a quote

KELVION HOLDING GMBH

Germany

Double tube safety heat exchangers play an important role in applications where preventing media mixing in the event of a leak is paramount. They are widely used and accepted as standard in the chemical industry, power, heavy and light industry, oil & gas, marine, transportation, refrigeration and food & beverage sectors. Kelvion has a long track record in developing ground-breaking technologies always aiming to reach the highest levels of safety, environmental protection and cost-efficient operation. Our expert engineers are fully trained to provide you with the best-in-class solutions tailored to your specific requirements. As industries face ever stricter regulations for safeguarding requirements of environment and water supply, double tube safety heat exchangers are the technology of choice.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

Global energy consumption is constantly rising. The raw material required for vehicle operation, energy production and other products is predominantly based on crude oil and natural gas. Screw pumps are often used in the production of these valuable commodities. For decades, Leistritz has been an expert partner for the oil and gas industry, whether for pumping tasks in crude oil production using multi-phase pumps, transfer and injection pumps or in the transportation of crude oil using booster or pipeline start-up pumps. Leistritz pumps are also used in refinery processes.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

As the leading provider of metal forming presses we are setting the standard worldwide. Our expertise in plant engineering and process technology is unique. This is because the individual performance features from the design to the startup of the equipment create a coherent and complete solution from a single source. Our hydraulic presses for metal forming are at home in cold and hot forming. From turbine disks for aircraft to pipeline pipes in the oil and gas industry to longitudinal beams in trucks: In our key industries of automotive, energy, rail and aerospace, we offer the right solution for every product. We supply not only the press, but also the associated process technology. Our range of services includes forging, thick sheet metal forming, raw forming, sheet metal forming and ring rolling. Our special systems for metal forming offer the perfect balance between the use of standard components and a custom-made design.

Request for a quote

STOBA SONDERMASCHINEN GMBH KG

Germany

CAM supported 6axis robot for economical ECM deburring tasks e.g. hydraulic blocks Effective even with small quantities, e.g. large pump housing from the oil and gas industry Precise deburring results with high repeatability CAD/CAM supported ECM machining strategy Integrated cathode changer for performing various deburring tasks Determination of workpiece zero point via 3D touch probe, e.g. Renishaw OMP 40

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Chemical Process Industry / Oil & Gas Industry Our vacuum and compressor systems maximize output and efficiency while minimizing maintenance and environmental pollution. Made of stainless steel and other sophisticated materials, they handle explosive and corrosive gases safely and efficiently. Pulp & Paper Industry Providing vacuum pumps and related equipment to the pulp & paper industry is a Gardner Denver Nash specialty. We are well known as an industry leader in engineered vacuum systems and water removal for paper machines. NASH vacuum pumps are used throughout the forming and press sections of a paper machine. Power Industry For over half a century, NASH has been the manufacturer of choice for air removal systems in steam cycle power generation plants throughout the world. NASH condenser exhauster packages efficiently remove inward air leakage from the condenser and improve the efficiency of the turbine under all operating conditions. Other Industries For more than 100 years, Nash has engineered liquid ring vacuum pumps, liquid ring compressors and engineered systems for the toughest applications. Our systems operate dependably for decades in filter applications, refineries, the sugar industry, in the food processing industry, mining and many more applications.

Request for a quote

ARUP ALU-ROHR UND PROFIL GMBH

Germany

For heavy-duty engine cooling, we offer copper-brass radiator tubes that can withstand the heat and pressure demanded by the oil and gas, power generation, and industrial markets. We also offer dimpled tube designs for specialized high-performance applications. • Profiles from 9 mm to 22 mm in tube height • Metal strip gauges as thin as 0.127 mm • Available dimpled or smooth, uncoated or coated, with both leaded and lead-free solder • Multiple pre-tooled profiles in long lengths available for short lead times • A wide array of brass alloys available, including the industry standard 85/15, 70/30, 65/35, and cupro-braze, with corrosion-resistant inhibitors

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

We also supply renowned customers on an international level with our products for conveying technology (gas and oil extraction) and their gear units. Here is an overview of our production possibilities: Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible We manufacture for different customers: railway, wind power, shipping, conveyor technology, industry and special machine construction. Production is carried out according to customer drawings and standards. Further information in the first interview. We look forward hearing from you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Oil and gas industry - Import exportNumber of results

17 ProductsCountries

Company type

Category

- Gas and oil - exploitation (2)

- Measurement - Equipment & Instruments (2)

- Oil - drilling and extraction (1)

- Pumps (1)

- Pumps, hydraulic (1)

- Air-conditioning systems, vehicles (1)

- Forming - steels and metals (1)

- Foundry machines - centrifugal (1)

- Heat exchangers (1)

- Lighting, emergency and safety (1)

- Pipes and tubes, copper (1)

- Plastic floor coverings (1)

- Screw cutting - steels and metals (1)

- Seals (1)

- Welding, soldering and brazing - equipment and supplies (1)