- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wiring

Results for

Wiring - Import export

DIETZ GMBH

Germany

Bent wire parts represent a separate part of our production range. Bent parts differ from springs such as extension springs, compression springs and wave springs in terms of how they are produced. This type of spring is not only processed with automated machinery, but also involves a considerable amount of special handling, which we perform using our range of state-of-the-art equipment. Precision production with our high-tech machinery: Our range of machinery with an in-house toolmaking workshop enables three-dimensional bent parts to be produced with a wide variety of forms and with specialised finishes applied to the ends. Our range of machining processes includes: Bevelling, embossing, thread cutting, thread rolling, turning and milling. For bent wire parts, both CNC bending and mould-based bending are possible as production solutions.We process wire thicknesses of 0.20 to 8.00mm.Tool-based: 0.50 to 8.00 mm. Coating of part surfaces: Oiling, Vibratory finishing, Galvanisation.

Request for a quote

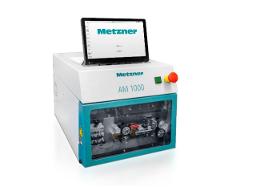

METZNER MASCHINENBAU GMBH

Germany

This special Metzner development is able to process cable wires with a diameter of up to 28 mm. The cycle time for this is 2000 mm / 35 seconds. The processing steps include long slitting, sawing, circumferential cutting, stripping, brushing and depositing. An integrated ink jet printer labels the cable wires with information or markings. As the heart of the processing method, Metzner uses a newly developed stripping head that combines a rotary cut with a powerful clamping and simultaneous rotation of the material. This enables a high-precision, multi-stage radial cut through the various layers of material. Microscopic quality inspection confirms that the processing is flawless with no scratches, pressure or abrasion marks. In addition to the high machining quality, the machinery also offers special precision: both the overall length and the machining position are maintained with an accuracy of 0.2 mm. The machine can process cable wires with diameters up to 28 mm.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The specially developed production line can unwind, label, roughen, cut to length, strip, wind, bind and automatically deposit the cable wires. The material to be processed is unwound by a motorised unwinder and fed to a thermal transfer printer via a straightener. The latter prints the cable with two QR codes and a serial number. This ensures that each cable can be identified throughout the entire processing and manufacturing process and assigned to the stations which have already passed through. This traceability offers great advantages – for example in the diagnosis of faults. The cable then passes through a roughening station, which lightly roughens the material surface so that the connector overmoulding adheres better later on. An AM 3550 from Metzner Maschinenbau cuts to length and strips the cable, which is then transported to the winding station and onwards by a gripper to the binding machine. The latter winds the cable to form a cable ring.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The powerful "universal cutting machine" with superior pulling and cutting strength. The contact pressure between the conveyor belts is pneumatically controlled and opens and closes automatically when the cover is opened and closed. Ideal for solid and dimensionally stable materials. Metzner also offers the Variocut in three “Red – Green – Blue" equipment lines. Each equipment variant is based on the same basic model with the same high-quality mechanical components. The individual models differ in speed, control and the interfaces for peripherals.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The »All-rounder« with particularly gentle and fine adjustment of the pressure between the transport belts. Ideal for soft and elastic material. The ST-OB is available in Red or Green versions. The Metzner ST-OB is for cutting cables & strands up to 30 mm diameter. Thanks to the gentle adjustment of the pressure between the transport belt also optimal for cutting rubber seals. WIDE SPECTRUM The cut-to-length machines of the ST-OB range have convincing precision, compact construction and processing spectrum for products such as cables, wires, braided cables, shrink-fit tubes, and numerous other materials.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZNER MASCHINENBAU GMBH

Germany

The cable processing machines in the AM 3800 range are characterised by their outstanding cutting and haul-off power and their modular, robust and long-life construction for continuous use in industrial applications. These machines outstandingly combine power and versatility. Equipped with cutting power for cables up to 70 mm sectionand 20 mm diameter, they are the ideal solution for an unusually wide spectrum of applications. Depending o the processing demands, numerous knife contours and technologies are available: the patented double-knife system allows different processes to be performed in a single working pass. The circumferential rotary cut offers an exact cutting round cables with very thin or tough insulation outer cover.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The AM 3000 range of cable processing machines are distinguished by cutting and haul-off power and their convincing modular, robust and long-life construction for continuous industrial working. There are different models with different cutting powers and specifications. To match the processing requirements, numerous knife contours and technologies are available: The patented „ double-knife system“ facilitates different processing in a single working pass, the circumferential rotary technology offers exact circular cutting for cables with very thin or rigid outer insulation cover and for co-axial cables. Every model is equipped as standard with a full set of interfaces for peripheral equipment and IT integration. The machines can easily be converted into complete production lines, thus further increasing the process automation.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The Metzner AM 1000 is a sensation among the tabletop units. The automatic cutting and stripping machine processes cables, strands and wires up to 9 mm diameter and 6mm² cable cross-section with a special cutting and pull-off force (optional 10 mm², depending on material). The presettings are conveniently made via the modern 12" touch panel, where the operator can define all processes. Thanks to the sensors for diameter and material recognition, the AM 1000 works extremely precisely. Another special feature is the tool-free replacement of guides and rollers. This means that the AM 1000 can be changed over in just one minute. With the extensive interface preparation, the machine can be optimally expanded with peripheral devices and adapts to all customer requirements. The compact design with retractable touch-screen and the low weight of only 28 kg also offer special comfort. This makes the AM 1000 especially easy to transport.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Multiple EM 600 stations in combination with a cost-effective transfer system provide the additional benefits of the EM 700 series: higher degree of automation, no limit to the number of stations, modular and scalable, single- or double-sided processing

Request for a quote

NORIS GROUP GMBH

Germany

Stainless-steel/brass screw-in sensor, Pt100/Pt1000. Compact and robust design. Simple assembly via screw-in thread. In a stainless-steel or brass version. Available as 2-wire or 3-wire. Maintenance-free. Compatible measuring transducers, limit value switches and analogue indicators available. Design available with a Pt100 or Pt1000 measuring element.

Request for a quote

LEONI DRAHT GMBH

Germany

Round copper wires made from Cu-ETP1 and Cu-OF1 in bare, tin-plated, nickel-plated, silver-plated or gold-plated, soft annealed. Single-wire diameter ranging from Ø 0.05 mm to Ø 0.51 mm. Number of wires used for strands: between 3 and 24 wires (subject to single-wire diameter).

Request for a quote

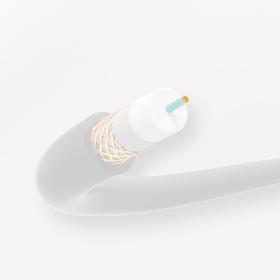

LEONI DRAHT GMBH

Germany

High-precision silver-plated single wire used as core for coaxial cables. Size range from Ø 0.10 mm to Ø 1.8 mm, manufactured on a specially designed machine. HF wire is characterised by a highly constant diameter, outstanding centricity and an extremely pure surface.

Request for a quote

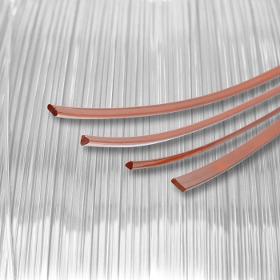

LEONI DRAHT GMBH

Germany

Wires with a particular shape (neither round nor flat wire). Subject to our customers’ specification there are various conceivable solutions such as triangle, polygon, bones or trapeze shape, and many more. Made from Cu-ETP1 and Cu-OF1 in bare, soft annealed or hard. LEONI Histral® alloys upon request. Cross-section: up to approx. 2.5 mm², depending on shape, further cross-sections upon request. Profile wires are mainly suitable for electrical conductors in a plastic profile and for busbars. They are space saving and have bigger contact areas. Certain shapes give a more secure hold in plastic profiles.

Request for a quote

LEONI DRAHT GMBH

Germany

Round copper wire made from Cu-ETP1 and Cu-OF1 in bare, tin-plated, nickel-plated, silver-plated or gold-plated, hard or soft annealed. Single wire diameter ranging from Ø 0.04 mm to Ø 1.8 mm. Single wire for high-frequency (HF) technology: High-precision silver-plated single wire used as core for coaxial cables, size range from 0.10 mm to 1.8 mm. This single wire is manufactured on a specially designed machine and is characterised by a highly constant diameter, outstanding centricity and an extremely pure surface.

Request for a quote

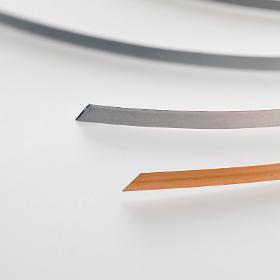

LEONI DRAHT GMBH

Germany

Flat copper wire made from Cu-ETP1 and Cu-OF1 in bare. Thickness: 0,038 mm – 1,0 mm Width: 0,80 mm – 6,0 mm Our flat copper wires are absolute burr free. They are characterised by maximum precision and originally round edges, particularly suitable for busbars, flat conductors or shielding.

Request for a quoteResults for

Wiring - Import exportNumber of results

16 ProductsCompany type