- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vibration measurements

Results for

Vibration measurements - Import export

EDDYLAB GMBH

Germany

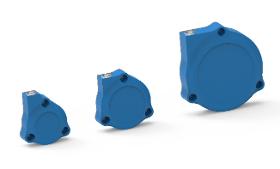

With an extended measuring range up to 45mm, the new eddy current sensor series completes the product portfolio of eddylab GmbH and at the same time combines all advantages of a non-contact eddy current measuring principle: With wear-free distance and displacement measurement, eddy current sensors are characterized by highest precision and dynamics. The new T14/T20/T40 series can withstand extreme temperatures in a range of -40...+150 °C without any problems and is insensitive to external influences such as dirt and dust. The new sensors with measuring ranges between 14 mm and 45 mm are also extremely compact and robust. This makes them ideal for use in difficult industrial environments or vibration measurements with larger amplitudes. Together with the TX electronics from eddylab GmbH and the eddy current software eddyMOTION, measurement data can be analyzed, visualized, and documented.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

Sensors and accessories for vibration measurement and Condition Monitoring Large selection of vibration sensors accelerometers, displacement sensors, VIBCODE transducer and triaxial sensors Accelerometers measure vibration acceleration, shock pulse (roller bearing condition) and pump cavitation Also available in compact size, for lowspeed machines and as combi sensors for vibration and temperature Patented tandempiezo technology eliminates the disadvantages of conventional sensors Highquality signal transmission over long distances up to 1,000 meters (3,200 feet) with current line drive (CLD) signal amplification Various mounting types EX / ATEX versions available Temperature probes, keyphasers, cables, adaptors and tools available

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

Safe, simple, precise The new VibScanner 2 Ex is a nextgeneration, explosion protection system for quickly detecting machine vibration in hazardous work environments. Measuring simultaneously on three axes, the VibScanner 2 Ex sets the benchmark for fast and accurate measurements of machine, gear, and bearing issues. This is the ultimate tool for fast and accurate machine vibration measurements. The VibScanner 2 Ex heightens efficiency and data quality. In just a quarter of the time of a standard datacollector, it precisely measures available data in three axes. Equipped with a triaxial sensor, it requires only one measurement point and the click of a button to begin collecting machine data. This device is ideal for routebased maintenance jobs in environments where explosion protection standards are required. Its rugged magnetic foot of the triaxial sensor fits perfectly on the housing of any motor, pump, fan, or other rotating device, detecting vibration right near the source.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

A unique handheld measuring device with which even untrained personnel can easily and effectively measure machine vibration on rotating machinery. Thanks to its forwardlooking measuring principle and data acquisition across three axes with the triaxial sensor, all relevant condition information is recorded with the touch of a single button. And at a measurement speed that opens up fully new dimensions. Not only is the VIBSCANNER 2 a breakthrough in terms of measurement speed and precision, but also through its robustness and its intuitive operating concept. The intuitive graphical user interface assists the employee en route in taking repeatable errorfree measurements. The device provides him/her with the exact information about the status of the measurement locations and the progress of the route.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Linear encoders from HEIDENHAIN fornumerically controlled machine tools can be used nearly everywhere. They are ideal for machines and other equipment whose feed axes are in a servo loop, such as milling machines, machining centers, boring machines, lathes and grinding machines. The benefi cial dynamic behavior of the linear encoders, their high permissible traversing speed, and their acceleration in the direction of measurement predestine them for use on highly-dynamic conventional axes as well as on direct drives. The linear encoders with full-size scale housing are characterized by their sturdy construction, high resistance to vibration and large measuring lengths. The scanning carriage is connected with the mounting block over an oblique blade that permits mounting both in upright and reclining positions with the same protection rating.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DR. JOHANNES HEIDENHAIN GMBH

Germany

Linear encoders from HEIDENHAIN fornumerically controlled machine tools can be used nearly everywhere. They are ideal for machines and other equipment whose feed axes are in a servo loop, such as milling machines, machining centers, boring machines, lathes and grinding machines. The benefi cial dynamic behavior of the linear encoders, their high permissible traversing speed, and their acceleration in the direction of measurement predestine them for use on highly-dynamic conventional axes as well as on direct drives. The linear encoders with full-size scale housing are characterized by their sturdy construction, high resistance to vibration and large measuring lengths. The scanning carriage is connected with the mounting block over an oblique blade that permits mounting both in upright and reclining positions with the same protection rating.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

Vibration analysis in explosive environments VIBXPERT EX is a highperformance, intrinsically safe, fullyfeatured data collector, vibration analyzer and field balancer for easy condition monitoring and troubleshooting of rotating equipment in explosive environments such as petrochemical plants, refineries, offshore oil rigs, etc. VIBXPERT EX collects field data including vibration information, bearing condition, inspection and process data and seamlessly integrates with the OMNITREND Center software platform for indepth analysis. The modular firmware structure allows you to upgrade the VIBXPERT EX from a route data collector to a fullblown troubleshooting device with advanced features such as coast down/runup measurements, event recording, ODS & modal analysis and crosschannel phase measurement.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

The Fluke 3563 combines a highfrequency piezoelectric sensor and insightful software analytics, enabling maintenance teams to regularly monitor and analyze vibration readings for a facility’s productioncritical assets. Its smart battery management lets maintenance pros determine the data transmission rate and adapt and extend the sensor battery’s life while still getting the data required. The sensor’s LIVEAsset Portal software application includes customizable frequency band measurements, automatically generated thresholds based on asset details, trend visualization, and frequency identification graphs. These views enable users to determine which fault is causing a problem to an asset and the cause of the fault. With this analysis, users can evaluate critical nextstep actions to take. The result is extended peak operating performance and more efficient maintenance team use – delivering increased business value from maintenance operations.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

Imbalances on rotating drive shafts can be detected and eliminated with the VIBXPERT II balancer. The smart measuring principle and the powerful computing capacity enable balancing on one or two planes. Various operating modes are available for balancing, so that a perfect result is always achieved. VIBXPERT II Balancer can be upgraded to a highperformance condition monitoring device VIBXPERT II, including all operating modes for machine condition monitoring.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

The mobile solution for machinery health monitoring The VIBXPERT II from PRUFTECHNIK is the mobile power package for fast and reliable recording and analysis of machine condition data. After a very short measuring time, the current machine status data is shown on the color display. The maintenance expert can analyze the data on site. From the recorded machine condition data, all values can be read from the various characteristic value modes that are important for an exact machine condition analysis. The device is used directly on site at the machine, from the machine hall to the diesel generator of an oil tanker or from a bucket excavator to a hydroelectric turbine. The robust design enables both fast and complex interventions. Whether in clinically clean systems, or harsh industrial environments. VIBXPERT II sets the standard in mobile machine and plant condition monitoring.

Request for a quoteResults for

Vibration measurements - Import exportNumber of results

11 ProductsCompany type