- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- test stands

Results for

Test stands - Import export

PAUL BOETTGER GMBH & CO. KG

Germany

Test Tube, Screw Cap, 16/57 mm, Round Bottom, Standing Rim

Request for a quote

PAUL BOETTGER GMBH & CO. KG

Germany

Test Tube, Screw Cap, 20/76 mm, Round Bottom, Standing Rim

Request for a quote

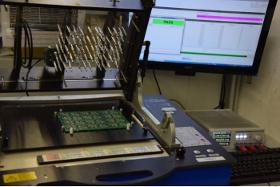

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Test contacts on the circuit board, produced for just this purpose, are contacted by fine, spring-loaded test pins. Depending on the series size, the in-circuit test can take place manually or in an automated fashion. In combination with other test processes, including tests without test contacts, over 90 percent of all errors can be detected.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Placement tests, checking the electrical and software functionality, launch tests – depending on your individual requirements and your component, we will develop a test strategy and tune the tests to fit with each other. Our comprehensive test development methodology accelerates processes running all the way to the delivery of your product and reduced testing costs.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. When planning tests, we work to your test specifications or develop a cost-optimised, efficient concept. In our tests, we simulate real usage conditions. In this way, we make sure that devices, systems or components will function correctly. Quality management at PRUFREX also includes developing efficient testing strategies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DEBANG EXPORT & IMPORT GMBH

Germany

Immerse yourself in the unparalleled allure of 1664 Kronenbourg, an extraordinary beer that embodies the essence of French artistry and brewing excellence. With every sip, embark on a journey through centuries of refined craftsmanship, carefully nurtured to perfection for your ultimate indulgence. A Symphony of Flavors: Delight your senses with the harmonious symphony of flavors that dance on your palate. This exceptional lager boasts a delightful balance of crisp, smooth, and subtly sweet notes, culminating in a rewarding and memorable taste experience. Brewed with Passion: Crafted with unwavering passion by skilled artisans, each drop of 1664 Kronenbourg is a testament to the dedication and artistry poured into every bottle. Meticulously selected ingredients harmonize to create an unmatched masterpiece that stands the test of time. Elegant Sophistication: Emanating an air of sophistication

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The NTS is designed for testing and servicing fuel injectors of large diesel engines. Use NTS for examining the spray pattern, for leak testing of the needle seating and for. Features The infinitely adjustable testing pressure is is generated by means of an air powered double acting high pressure pump. The attachment for clamping the fuel injector is of rigid design and swivel-mounted so that the injector can be turned to horizontal position for ease of servicing. The transparent container for collecting the testing liquid is provided with an outlet for removing the liquid by suction.

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The hydraulic industrial shock absorber of the C-series (COMPENSER®) is the ideal hydraulic buffer for storage and retrieval machines or smaller conveyor systems, crane systems, test stands etc. in light to medium mechanical engineering. Due to its short design, this hydraulic buffer (COMPENSER®) can be used in a spacesaving manner as limitation of the end position (as emergency end stop) in industrial applications. In addition, the low reset force allow operational pushin cycles at creep speed. Design & Function: The piston rod 2 enters the metering tube 3. The damping medium flows from the pressure chamber 6 through the throttle orifices 4 of the metering tube 3 into the volume balance chamber 5. The nitrogen gas between the outer tube 7 and the metering tube 3 is compressed and stores the energy required for the reset of the piston rod. When the piston rod 2 returns to the initial position, the damping medium flows back into the pressure chamber 6.

Request for a quoteResults for

Test stands - Import exportNumber of results

9 ProductsCountries

Company type