- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special steel

Results for

Special steel - Import export

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing steel / Special PTFE coated Maintenance-free dry sliding bearing | DIN 1494 / ISO 3547 TEF-MET/P is a versatile dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, it is very well suited for lubricated applications (e.g. hydraulic oil lubrication). For technical details, please visit the product page on our website!

Request for a quote

DIETZ GMBH

Germany

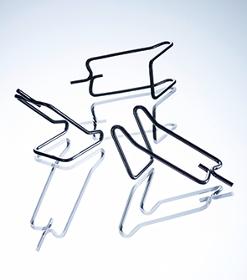

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

BDSENSORS GMBH

Germany

The industrial pressure transmitter DMP 336 was especially developed for hydrogen applications and can also be used with other technical gases (e.g. oxygen). This is achieved by using an alloy based on 316L which prevents hydrogen embrittlement of the media-wetted parts. Level of hydrocarbon and particle contamination are significantly reduced by special treatment during production and cleaning. An IS- version is optionally available for explosion-protected applications zone 0 / 20. Features: — nominal pressure: 0 ... 16 up to 0 .... 1000 bar — accuracy: 0,5 % FSO — wetted parts in special stainless-steel — insensitive to pressure peaks — high overpressure capability — oil and grease free according to ISO 15001 (e.g. for oxygen applications) Optional Features — IS-version Ex ia = intrinsically safe for gases and dust

Request for a quote

WAELAG WÄLZLAGER VERTRIEBS- GMBH

Germany

The LU-Series is similar to the PU-Series, but without the resin recirculation way. Only available in special high carbon steel and size 15. AL sliders with light- (Z) or medium (H) preload are standard stock items with prompt delivery.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Right-hand cutting reamer with expanding blades. Due to the unique Hunger relief grinding operation the blades have a progressively increasing clearance angle giving a soft cutting action. Starting with size D 12 the adjusting nut is marked with an annular scale. One graduation of the scale corresponds to a change of the reamer diameter by 0,01 mm. The reamers are available with standard blades made of high quality special steel to ensure superior cutting performance. The reamers are also available with hard chromium coated blades. The hard chromium coating has superior hardness in combination with a low friction coefficient. Thus reamers of the "hard chromium" series are particularly suitable for reaming abrasive materials and materials with a tendency to adhere to and to build-up the cutting edge.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Right-hand cutting shell reamer with expanding blades. Due to the unique Hunger relief grinding operation the blades have a progressively increasing clearance angle giving a soft cutting action. The reamer fits on a tool bar and may be positioned along the tool bar at any desired position. The reamer is automatically locked in place on the tool bar by an expanding spring coupling as soon as the reamer blades are brought into engagement with the bore. Expanding tool bar guides and supporting fixtures for the tool bar are available to ensure excact alignment of the tool bar when reaming a series of aligned holes. The adjusting nut is marked with annular scale. One graduation of the scale corresponds to a change of the reamer diameter by 0,02 mm. The reamers are available with standard blades made of high quality special steel to ensure superior cutting performance. The reamers are also available with hard chromium coated blades.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The universal reamer for all types of holes, particularly for in-line reaming of two or more holes and for reaming very long holes. Description Right-hand cutting reamer with expanding blades. Interchangeable pilots with guide sleeves at the front as well as at the back of the reamer. The guide sleeves provide for exact alignment between the hole being reamed and the other mating holes. A special bayonet coupling with mating cones between each pilot and the reamer body ensures correct alignment. Due to the unique Hunger relief grinding operation the blades have a progressively increasing clearance angle giving a soft cutting action. The adjusting nut is marked with a annular scale. One graduation of the scale corresponds to a change of the reaming diameter by 0,02 mm. The reamers are available with standard blades made of high quality special steel to ensure superior cutting performance. The reamers are also available with hard chromium coated blades.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The versatile reamer for reaming longer holes and adjacent mating holes. Description Right-hand cutting reamer with expanding blades. Integral pilot with guide sleeves at the front end of the reamer. The guide sleeve provide for exact alignment between the hole being reamed and the other mating hole. Due to the unique Hunger relief grinding operation the blades have a progressively increasing clearance angle giving a soft cutting action. The adjusting nut is marked with a annular scale. One graduation of the scale corresponds to a change of the reaming diameter by 0,01 mm. The reamers are available with standard blades made of high quality special steel to ensure superior cutting performance. The reamers are also available with hard chromium coated blades. The hard chromium coating has superior hardness in combination with a low friction coefficient.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The reamer for reaming longer holes and adjacent holes to be reamed in line with each other. Description Right-hand cutting reamer with extra-long expanding blades. The blades are approximately 2/3 longer than the blades of reamer type D. Due to the unique Hunger relief grinding operation the blades have a progressively increasing clearance angle giving a soft cutting action. The reamers are available with standard blades made of high quality special steel to ensure superior cutting performance. The reamers are also available with hard chromium coated blades. The hard chromium coating has superior hardness in combination with a low friction coefficient. Thus reamers of the "hard chromium" series are particularly suitable for reaming abrasive materials and materials with a tendency to adhere to and to build-up the cutting edge.

Request for a quoteResults for

Special steel - Import exportNumber of results

11 ProductsCompany type