- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shaft couplings

Results for

Shaft couplings - Import export

JAKOB ANTRIEBSTECHNIK GMBH

Germany

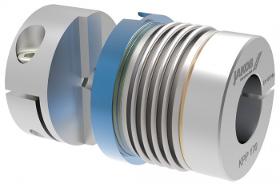

• High-speed version for the highest operating speeds • Rotationally symmetrical clamping hub for optimum balancing quality

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• for direct mounting in a hollow shaft • 4-corrugation bellows - short design • Torque range: 2 - 600 Nm • Shaft diameter: D1: 3 - 68 mm / D2: 8 - 48 mm • internal axial buffer

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• simple installation with radial EASY-clamping hub on both sides • steel hub - welded design - temperatures up to 350°C • 2-, 4- or 6-corrugation bellows - short design - high torsional stiffness • Torque range: 40 - 1.300 Nm • Shaft diameter: 12 - 90 mm » KG-VA = stainless steel optional

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• conical hub on both sides • straight bellow - long design • Torque range: 25 - 2.500 Nm • Shaft diameter: 10 - 102 mm • low storing forces – high torsional stiffness

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• simple installation, with EASY-Clamping hub on both sides • 6-corrugation bellows - cost-effective standard series • Torque range: 20 - 1.800 Nm • Shaft diameter: 8 - 85 mm

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• simple installation with radial EASY-clamping hub on both sides • straight bellow - long design • low restoring forces – high torsional stiffness • Torque range: 25 - 1.500 Nm • Shaft diameter: 8 - 85 mm

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• simple installation - split-hub design • wear and maintenance free • variable length stainless steel version up to 350°C • Torque range: 10 - 1.200 Nm • Shaft diameter: 7 - 85 mm

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• steel hub - welded design - temperatures up to 350°C • 2-, 4-, or 6-corrugation bellows - short design - high torsional stiffness • Torque range: 30 - 1.000 Nm • Shaft diameter: 10 - 90 mm • stainless steel

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• simple installation - now also with splitted hub design on both sides • stainless design - variable length • Torque range: 10 - 900 Nm • Shaft diameter: 6 - 75 mm

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• simple installation - splitted hub design on both sides • steel hub - welded design - temperatures up to 350°C • customized length with 2-, 4- or 6-corrugation bellows • Torque range: 20 - 1800 Nm • Shaft diameter: 8 - 85 mm

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• conical hub on both sides • 6-corrugation bellows • Torque range: 10 - 4.000 Nm • Shaft diameter: 6 - 102 mm • cost-effective standard series

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• several hub variants with a backlash free nose groove principle • blind assembly (plug in) possible - backlash free • sturdy whole metal version for temperatures up to 200°C • Torque range: 10 - 600 Nm • Shaft diameter: 6 - 70 mm

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• Torque range: 4.000 - 70.000 Nm • 3-parted construction- easy to fit - variable in use • flange hub or conical ring hub • Shaft diameter: 60 - 220 mm • backlash free – exact torque transfer • high torsional stiffness - low moments of inertia • high tolerance of shaft displacements

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• conical hub on both sides - aluminium design • ''high speed- version'' for a speed up to 30.000 rpm • low mass moment of inertia - high balance quality • Torque range: 15 - 600 Nm • Shaft diameter: 6 - 60 mm

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• simple installation with optional radial EASY-clamping hub on both sides • steel hub - welded design - temperatures up to 300°C • 2-, 4- or 6-corrugation bellows - short design - high torsional stiffness • Torque range: 5 - 20Nm • Shaft diameter: 6 - 20 mm » KG-VA = stainless steel optional

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• for standardized interface connection DIN - EN - ISO 9409 - 1 • two-part connection flange • compact design • Torque range: 40 - 1800 Nm • shaft diameter: 12 - 90 mm • simple installation with radial EASY-clamping hub at output side

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

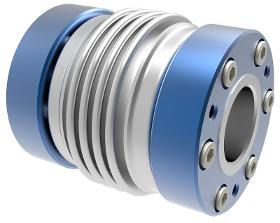

• radial clamping hub on both sides • cost-effective, very short design, standard series • plug in, backlash free, oscillation dampening • Torque range: 8 - 2.000 Nm • Shaft diameter: 8 - 90 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• simple installation due to split-hub design • can be combined with EKM - hub or ESM-A - hub • mountable without disassembly of motor • Torque range: 15 - 2.000 Nm • Shaft diameter: 8 - 100 mm

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• standard version with radial clamping hub • high torsional stiffness - flexible • Torque range: 0,4 - 12 Nm • Shaft diameter: 3 - 24 mm • Temperature range -40 to +200°C

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• stainless steel version • easy to assemble clamping hub • plug-in, backlash-free and vibration dampening • torque range: 8 - 500 Nm • shaft diameter: 8 - 55 mm

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

In rotary encoders with integral bearing and stator coupling, the graduated disk of the encoder is connected directly to the shaft to be measured. The scanning unit is guided on the shaft via ball bearings, supported by the stator coupling. During angular acceleration of the shaft, the stator coupling must absorb only that torque resulting from friction in the bearing, thereby minimizing both static and dynamic measuring error. Moreover, the coupling mounted on the stator compensates axial motion of the measured shaft. Other benefits of the stator coupling are: Simple mounting Short overall length High natural frequency of coupling Hollow-through shaft possible

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

The universal brackets for shaft alignment Stored premounted in the case for instant usage Mounts on machine shaft in less than a minute Standard chains fit shaft and coupling diameters of approx. 15 mm to 200 mm / 5/8“ to 7 7/8“ This universal bracket set contains all parts needed for quick, stable mounting of the measurement components. It fits onto any shaft or coupling approx. 15 mm to 200 mm /5/8" to 7 7/8“ in diameter. Stored premounted in the case, the brackets are always ready to use and quickly in place. The chain may be used as a plumb bob to accurately determine the dimension from coupling center to front foot.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

HEIDENHAIN angle encoders with integral bearing are characterized in particular by very high system accuracy. The integral bearing in the encoders eliminates any effect on measuring accuracy from the bearing of the machine components. The integrated stator coupling in the RCN/RON/ECN series encoders guarantees lowest possible error from the effect of tolerances in the shaft coupling. All angle encoders with integral bearings feature shaft seals that ensure resistance to contamination (IP64 protection). These encoders enjoy an entire spectrum of possible applications in machine tools, measuring machines, telescopes, printing machines and many other areas. Incremental measuring method Large hollow shaft diameter (up to 60 mm) Integrated stator coupling Compact size for limited installation space System accuracy includes the deviation caused by the shaft connection Outstanding dynamic response Simple installation Typical field of application: Rotary tables Swivel heads

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

In rotary encoders with integral bearing and stator coupling, the graduated disk of the encoder is connected directly to the shaft to be measured. The scanning unit is guided on the shaft via ball bearings, supported by the stator coupling. During angular acceleration of the shaft, the stator coupling must absorb only that torque resulting from friction in the bearing, thereby minimizing both static and dynamic measuring error. Moreover, the coupling mounted on the stator compensates axial motion of the measured shaft. Other benefits of the stator coupling are: Simple mounting Short overall length High natural frequency of coupling Hollow-through shaft possible

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

In rotary encoders with integral bearing and stator coupling, the graduated disk of the encoder is connected directly to the shaft to be measured. The scanning unit is guided on the shaft via ball bearings, supported by the stator coupling. During angular acceleration of the shaft, the stator coupling must absorb only that torque resulting from friction in the bearing, thereby minimizing both static and dynamic measuring error. Moreover, the coupling mounted on the stator compensates axial motion of the measured shaft. Other benefits of the stator coupling are: Simple mounting Short overall length High natural frequency of coupling Hollow-through shaft possible HEIDENHAIN ERN, ECN and EQN rotary encoders with integral bearing and mounted stator coupling are characterized by simple mounting and short overall length.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

In rotary encoders with integral bearing and stator coupling, the graduated disk of the encoder is connected directly to the shaft to be measured. The scanning unit is guided on the shaft via ball bearings, supported by the stator coupling. During angular acceleration of the shaft, the stator coupling must absorb only that torque resulting from friction in the bearing, thereby minimizing both static and dynamic measuring error. Moreover, the coupling mounted on the stator compensates axial motion of the measured shaft. Other benefits of the stator coupling are: Simple mounting Short overall length High natural frequency of coupling Hollow-through shaft possible

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

In rotary encoders with integral bearing and stator coupling, the graduated disk of the encoder is connected directly to the shaft to be measured. The scanning unit is guided on the shaft via ball bearings, supported by the stator coupling. During angular acceleration of the shaft, the stator coupling must absorb only that torque resulting from friction in the bearing, thereby minimizing both static and dynamic measuring error. Moreover, the coupling mounted on the stator compensates axial motion of the measured shaft. Other benefits of the stator coupling are: Simple mounting Short overall length High natural frequency of coupling Hollow-through shaft possible HEIDENHAIN ERN, ECN and EQN rotary encoders with integral bearing and mounted stator coupling are characterized by simple mounting and short overall length.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

HEIDENHAIN angle encoders with integral bearing are characterized in particular by very high system accuracy. The integral bearing in the encoders eliminates any effect on measuring accuracy from the bearing of the machine components. The integrated stator coupling in the RCN/RON/ECN series encoders guarantees lowest possible error from the effect of tolerances in the shaft coupling. All angle encoders with integral bearings feature shaft seals that ensure resistance to contamination (IP64 protection). These encoders enjoy an entire spectrum of possible applications in machine tools, measuring machines, telescopes, printing machines and many other areas. Absolute measuring method Hollow shaft diameter (up to 50 mm) Integrated stator coupling Simple installation Typical field of application: Rotational axes with reduced accuracy requirements

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

Your tool for nextgeneration machinery alignment ROTALIGN touch is the first laser shaft alignment system on the market to combine high precision onsite measuring tasks and cloud connectivity for worldwide data access and transfer. It features the unique sensALIGN 7 laser and sensor heads offering a full range of everyday alignment routines up to expert degree alignment jobs – such as cardan shaft alignment or coupling alignment. The singlelaser technology enables unrivaled precision, even in harshest conditions and on highly demanding jobs. ROTALIGN touch was designed by some of the world’s leading alignment experts to solve problems in the easiest way possible. The intuitively guided user interface can be operated by almost anyone – users just need to follow the three steps for any laser shaft alignment procedure dimension, measure, and result.

Request for a quoteResults for

Shaft couplings - Import exportNumber of results

31 ProductsCompany type