- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- series part

Results for

Series part - Import export

SCHMITTER HYDRAULIK GMBH

Germany

Cutting rings Category Screw connections, adapter a. accessories / Pipe connections 24° french series / Parts / Cutting rings / Steel Product number supplier 439024225

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Cutting rings Category Screw connections, adapter a. accessories / Pipe connections 24° french series / Parts / Cutting rings / Steel Product number supplier 439024225

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Union nuts Category Screw connections, adapter a. accessories / Pipe connections 24° french series / Parts / Union nuts / Steel Product number supplier 439014225

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Union nuts Category Screw connections, adapter a. accessories / Pipe connections 24° french series / Parts / Union nuts / Steel Product number supplier 439014225

Request for a quote

HOCHRAINER GMBH

Germany

Selection of sample parts from a wide variety of industries Send us your part, and we'll show you how to reduce your costs. Short cycle times are guaranteed with 2-shift operation. Scheduled work is possible at any time thanks to flexible production conversion. Our comprehensive materials store keeps production times short. From individual part to series.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VOXELJET AG

Germany

The VX500 is a 3D printer for industrial applications that has been tried and tested many times over in practice. These machines can be found wherever there is a demand for the straightforward production of prototypes and models. Despite their compact dimensions, they captivate with the features of a high-performance printer, such as multi-jet print heads, integrated material handling and job boxes. The machine is very fast, easy to operate and permits cost-effective production of both individual parts and small series alike. Plastic can be used as the particulate material. The machine's build space measures 500 x 400 x 300 mm. The VX500's print head system can achieve a resolution of up to 600 dpi. The thickness of a layer applied in one cycle is 150 µm. In addition, the VX500 concept is resource-friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For sliding properties improvement of machine parts, apparates and precision machinery, especially for microfinished surfaces For incorporation in plastics, sealings, packages, sintered metals and improvement of sliding properties For long-term or possibly lifetime-lubrication Advantages and benefits Reduces friction and wear in a wide temperature range High effectiveness due to high affinity of MoS₂ to metals Low friction at highest load capacities Low consumption based on forming of extreme thin sliding films Not electrically conducting and not magnetic Chemically stable except against halogenated gases, concentrated sulphuric- and nitric acidFor best adhesion, clean sliding surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply on small parts in series production by tumbling, under addition of small amounts powder and tumbling parts, until a complete MoS₂ film is formed. Brush the powder onto bigger surfaces.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For sliding properties improvement of machine parts, apparates and precision machinery, e.g. under the influence of oxygen, in vacuum or radioactive radiation Dry lubrication for tools or workpieces in cold- and thermoforming For incorporation in plastics, sealings, packages, sintered metals and improvement of sliding properties For long-term or possibly lifetime-lubrication Advantages and benefits Reduces friction and wear in a wide temperature range High effectiveness due to high affinity of MoS₂ to metals Low friction at highest load capacities Low consumption based on forming of extreme thin sliding films Not electrically conducting and not magnetic Chemically stable except against halogenated gases, concentrated sulfuric- and nitric acidFor best adhesion, clean sliding surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply on small parts in series production by tumbling, under addition of small amounts powder and tumbling

Request for a quote

SYSKOMP GMBH - EMICO

Germany

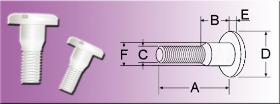

Suitable for the connection of pattern books, colour fans etc. To be used with appropriate female part of series 081... Material: PA 6 Colours: Last digits 500 = white Last digits 599 = black

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Thanks to its flexible operating concept – workshop-oriented programmability with HEIDENHAIN conversational programming or external programming – and its scope of features, it is especially suited for use on universal milling, drilling and boring machines for series and single-part production tool and die making manufacture of machines research and development prototype production and testing facilities repair departments educational and training institutes The TFT 15-inch color monitor shows a clear overview of all relevant information for programming, operating and inspecting the machine tool and control such as program blocks, comments and error messages. More information is provided through graphic support during program entry, test run and actual machining. The selectable split-screen display shows the part program blocks in one half of the screen and the graphics or the status display in the other half.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The TNC 620 is compact and easy to read. The TNC 620 is a compact but versatile contouring control for up to five controlled axes. Thanks to its flexible operating concept—workshop-oriented programmability with HEIDENHAIN conversational programming or offl ine programming—and its scope of features, it is especially suited for use on universal milling, drilling and boring machines for the following: Series and single-part production Toolmaking Machine building Research and development Prototypes and pilot plants Repair departments Training and education facilities And it offers the applicable features both necessary and helpful: Universal milling machines Free contour programming Milling cycles for complex contours Fast presetting with HEIDENHAIN touch probes Drilling and boring machines Cycles for drilling, boring and spindle alignment Cycles for linear and circular point patterns Five-axis machining with swivel head and rotary table

Request for a quoteResults for

Series part - Import exportNumber of results

12 Products