- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- seals for containers

Results for

Seals for containers - Import export

BILLI DICHTUNGSTECHNIK GMBH

Germany

The function of gaskets is to prevent the leakage of medium outside the equipment. Static seals are used in many applications such as plumbing and heating systems, sealing fasteners, containers and pipeline construction. They are washers, rings or frames which generally are adapted to the whole width of the sealing surface. They can be used for example in flange connections of pipelines, pumps, motors, valves, etc. The gaskets are made of various materials such as: Rubbers, fiber plates, synthetic plates, graphite, PTFE, etc.

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

assortment fiber sealing rings DIN 7603 The assortments contains: the most usual fiber sealing rings from 4 to 30 mm of inside - Ø steel sheet box 340X240X55 mm with plastic insert ... Category Sealings / Vulkanized fiber sealings / Assortments Product number supplier 101000

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

assortment fiber sealing rings DIN 7603 The assortments contains: the most usual fiber sealing rings from 4 to 30 mm of inside - Ø steel sheet box 340X240X55 mm with plastic insert ... Category Sealings / Vulkanized fiber sealings / Assortments Product number supplier 101000

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

assortment aluminium sealing rings DIN 7603 The assortments contains: the most usual aluminium sealing rings from 6 to 30 mm of inside - Ø steel sheet box 340X240X55 mm with plastic insert ... Category Sealings / Aluminum sealings / Assortments Product number supplier 100400

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For removing dust prior to maintenance and repair work, e.g. on magnetic plates, reading heads, audio-visual magnetic tape recording and playback heads, phonograph pick-ups, record turntables or phonograph records For cleaning vacuum sealing surfaces, sealing rings, high-voltage insulators, sample containers etc. For vacuum systems and device groups under clean-room conditions for semiconductor production Cleaning of opto-electronic reading units for bank checks and contactless cleaning of optical devices For maintenance of automated teller machines, quartz clocks or display panels For dedusting precision mechanical parts and assemblies in office machines, copiers, fax machines etc. Advantages and benefits Excellently suited for dedusting, blowing out and blowing off dust and liquids of all kinds Dry, oil-free compressed gas leaves behind no residues Replacement for ultrapure compressed air

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

The HELIO®MAT dryer station is part of the JETBOXX® system and features an independent JETBOXX® dryer with full functionality at each individual docking station. The material can be predried in removable drying containers at the dryer station. The drying container can be removed and brought to the processing machine if needed. It will be attached directly onto the feeding section there and the dried material can be processed. If the material should be kept dry on the machine, a JETBOXX® docking plate with dryer control are used in addition. HELIO®MAT is applicable for example as pre-drying station for quick material change, as dryer station for sampling batches, for batch drying for small quantities / sampling, for laboratory applications, or for cleanroom supply with hermetically sealed dry material containers. Material change without delay. No humidification. No cleaning issues.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

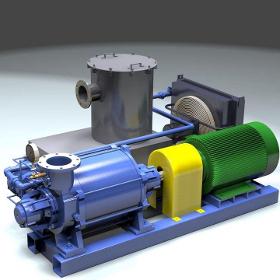

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quoteResults for

Seals for containers - Import exportNumber of results

8 ProductsCountries

Company type