- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- seal systems

Results for

Seal systems - Import export

BILLI DICHTUNGSTECHNIK GMBH

Germany

The function of gaskets is to prevent the leakage of medium outside the equipment. Static seals are used in many applications such as plumbing and heating systems, sealing fasteners, containers and pipeline construction. They are washers, rings or frames which generally are adapted to the whole width of the sealing surface. They can be used for example in flange connections of pipelines, pumps, motors, valves, etc. The gaskets are made of various materials such as: Rubbers, fiber plates, synthetic plates, graphite, PTFE, etc.

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Category Diesel technology / Sealings diesel fuel systems / Plugs Product number supplier 110243

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Category Diesel technology / Sealings diesel fuel systems / Nozzle rings Product number supplier 110240

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Category Compressed-air technology / Screw connections for air brake systems / Parts / Sealings / Brass/rubber sealing rings Product number supplier 101100

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Category Compressed-air technology / Screw connections for air brake systems / Parts / Sealings / Brass/rubber sealing rings Product number supplier 101099

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The innovative precision-volume-dispenser eco-PEN700 made by ViscoTec offers a wide range of applications for low to medium-viscosity dispensing. preeflow® eco-PEN is a rotating and perfectly pressure-tight displacement system. Self-sealing rotor/stator design. Conveyance action by medium displacement in the stator through controlled rotor rotation. Safe conveyance without any modification of the medium. With its suck back option, preeflow® ensures clean and controlled material or medium cut-off while preventing post-dripping effects.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Profiles and sealing systems often require ventilation holes or mounting holes. Drilling equipment from Metzner carries out these tasks. We provide the following solutions adapted to your specific requirements: - In-line as an eccentric drilling station for regular drilling at equal distances - In-line as travelling drilling station for drilling at the same or variable distance - In-line as "drilling beam", which carries out all drillings for an entire sealing profile with variable distances in one operation - Off-line for drilling in combination with final trimming The machine is equipped with drilling spindles with very high speeds of up to 60,000 revolutions per minute. An exact drill hole is thus achieved in a short cycle time. The geometry of the drills ensures that the waste falls to the outside.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

2 Component Fiber Sealing System impregnated with Graphite and MoS2 lubricant Pressure Capability is dependent on design of endrings. Characteristics Simple installation Use without barrier fluid Maintenance free Shaft protecting No adjusting of gland Re-pressurize in operation Operating range Velocity [v max]: 12 m/s Temperature: t = -40… +315 °C pH: 2 - 12 Density: 1.10 g/cm³ Pressure Capability is dependent on design of endrings. Main application Equipment which is badly accessible Worn shaft sleeves Non centric running shafts Suitable for Higher Temperature applications Accessories Special endrings made of HPU and PTFE/Graphite compound for non centric running shafts Form of delivery Unit for H- and P-Type: Cans 1 kg, hobbock of 25 Kg 2 Component System Component H: Is used for the basic manual fill of the stuffing box. Component P: Is used for Injection with press DVS TP 9000.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

2 Component Fiber sealing system impregnated with PTFE and special lubricant Pressure Capability is dependent on design of endrings. Characteristics Simple installation Use without barrier fluid Maintenance free Shaft protecting No adjusting of gland Re-pressurize in operation Operating range Velocity [v max]: 8 m/s Temperature: t = -10… +180 °C pH: 2 - 12 Density: 1.10 g/cm³ Pressure Capability is dependent on design of endrings. Main application Equipment which is badly accessible Worn shaft sleeves Non centric running shafts Pulper Suitable for Universal use Accessories HPU Endrings Form of delivery Unit for H- and P-Type: Cans 1 kg, hobbock of 25 Kg 2 Component System Component H: Is used for the basic manual fill of the stuffing box. Component P: Is used for Injection with press DVS TP 9000.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Application specific ring sets Improved properties are: Extrusion resistance, if high pressures have to be sealed and/or bigger gaps than the normally recommended max of 25 of the packing size are found. Wiper function, if any micro scaling is found on the stem and at reciprocating movement with control valves Blow out safety, when sealing high compressed gases and fumes Pliability, with low gland forces as well good reset and adaptability for example in applications with temperature cycles. Ring Set 3335 For Control Valves up to 400 °C. Ring Set 6655 For Control Valves and staem applications up to 600 °C steam. All rings are delivered as standard in skive cut. Ring Set 6660 For Valves up to 650 °C steam. This ringset offers minimal volumeloss. The rings in the sealing zone are split as standard in 2 halves or as option delivered with a skive cut. Top and bottom ring are delivered with skive cut. Soot Blower Ring Set For soot blower applications with steam temperature up to...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Rectangular braided tube packing Characteristics The elasticity of this gasket tape allows low uneveness of the flange surface The sealant can be reused after opening of flange Low cold flow Sealing of the cutted ends by inserted point lock Main application Metal, glass, ceramic flanges on boilers centrifuges pipe flanges tanklid housings Suitable for Flanges in General service Variant SL 4 from ePTFE Graphite Fiber SL 6 from PTFE Fiber with oil SL 19 from dry PTFE Fiber SL 44 l from expanded Graphite, integrated Inconel reinforcement and adhesive backing SL 44l Dimensions 3 x 12 mm 5 x 19 mm 6,3 x 25 mm Other dimensions and basic materials – on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Multilayer construction of expanded graphite with Inconel reinforcement Practical useful application data: max. temperature in oxidizing atmosphere: +450 °C Characteristics Universal suitable, rectangular preformed Sealing tape of expanded pure graphite with Inconel reinforcement Recommended gap width 0.5 mm, maximum gap width 1.0 mm Excellent adaptability on different housing forms and ovality Excellent transformation of axial compression into radial sealing force Operating range Temperature: t = -200… +650 °C pH: 0 - 14 Practical useful application data: max. temperature in oxidizing atmosphere: +450 °C Main application Fittings Valve pressure rings Suitable for Power plant Boiler houses Recommended minimum surface pressure at assembly 20 N/mm 2 Brettschneid Tape Form of delivery 5 x 12 mm in 1 kg Spool approx. 14 mtr 7.5 x 15 mm in 2.5 kg Spool approx. 18.5 mtr 10 x 15 mm in 2.5 kg Spool approx. 14 mtr 15 x 30 mm in 5 kg Spool approx. 9.5 mtr 19 x 30 mm in 5 kg Spool...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100 % PTFE Tape packing with cover braid and additional outside PTFE Tape Wrap Practical useful application data: max. temperature: +200 °C Characteristics Low coefficient of friction Good adaption to any kind of surface Non ageing or hardening Used as spiral guarantees simple assembly and disassembly in one piece Available in 2-15 mm Operating range Pressure [p max]: 20 bar, Velocity [v max]: 1 m/s Pressure [p max]: 20 bar, Velocity [v max]: 1 m/s Pressure [p max]: 100 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.45 g/cm³ Practical useful application data: max. temperature: +200 °C Main application Valve Packing, easy to use Suitable for Chemical industry Universal use Installation and maintenance shops

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

PTFE Powder with Graphite, Extruded Profile Practical useful application data: max. temperature: +180 °C Characteristics Good pliability, prevents wear of shafts through embedding of abrasive materials The use of bullrings is required Operating range Pressure [p max]: 10 bar, Velocity [v max]: 12 m/s Pressure [p max]: 20 bar Temperature: t = -100… +250 °C pH: 0 - 14 Density: 1.90 g/cm³ Practical useful application data: max. temperature: +180 °C Main application Valves Gate valves Flanges Agitators Centrifugal pumps Lids Suitable for Cold and hot water Alkaline solutions Acids Oils Grease Bitumen Asphalt Crystalline and abrasive media Food industry Variant S 50 Propaflon White made out of pure PTFE

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

ePTFE-Graphite Fiber with special Para-Aramid corners Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Characteristics Form stable, wear resistant, heat conductive packing, can be used as bullring Highest pressure resistance, practically no gap extrusion For high pressure plunger pumps up to 1,500 bar as die formed rings Highest pressure resistance Safe and universal packing for abrasive media Precompressed rings are recommended for applications in plunger pumps Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 1500 bar, Velocity [v max]: 2 m/s Pressure [p max]: 500 bar Temperature: t = -100… +280 °C pH: 2 - 12 Density: 1.35 g/cm³ Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Main application Plunger pumps Gate valves Suitable for High pressure plunger pumps and similar applications Bull rings Form of delivery This packing can be...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Combination Braid Made of PTFE and Para-Aramid Fiber with Run-In Lubricant Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar max. velocity centrifugal pumps: 15 m/s Characteristics Universal packing for abrasive media which need a reinforced, wear resistant and form stable packing Shaft protecting through good coefficient of fiction No contamination of media Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 500 bar, Velocity [v max]: 2 m/s Pressure [p max]: 250 bar Temperature: t = -100… +280 °C pH: 2 - 12 Density: 1.45 g/cm³ Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar max. velocity centrifugal pumps: 15 m/s Main application Centrifugal pumps Mixer Kneader Agitators Filter Extruder Refiner Suitable for Chemical industry Pulp and paper industry Form of delivery This packing can be manufactured from 6 to 40 mm square as well as in...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Characteristics Very form stable, Recommended shaft surface hardness: HRC 50 Good heat conductivity therefore reduced wear Extrusion resistant at bigger gaps, can also be used as bullring Ability to withstand high pressure Safe and universal packing for abrasive products Die formed rings are recommended Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 500 bar, Velocity [v max]: 3 m/s Pressure [p max]: 250 bar Temperature: t = -100… +280 °C pH: 2 - 12 Density: 1.45 g/cm³ Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Main application In all units with larger gap widths, or in solids containing media. Plunger pumps Fittings Gate valves Suitable for Further development as Trapez-Pack ® 12. Production in trapezoidal form and with special impregnation. This optimizes performance characteristics...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

PTFE Fiber with PTFE Blocking Agent and Silicone Free Run-In Lubricant Characteristics Highest chemical resistance for a packing in rotating equipment Pliable, easily compressible packing Self lubricating, dry running capability Shaft protecting surface hardness of HRC 25 is sufficient Non ageing Operating range Pressure [p max]: 15 bar, Velocity [v max]: 10 m/s Pressure [p max]: 100 bar, Velocity [v max]: 1.5 m/s Pressure [p max]: 100 bar Temperature: t = -50… +280 °C pH: 0 - 14 Density: 1.70 g/cm³ Main application Agitators Mixer Refiner Filter Slow speed Centrifugal pumps Valves, Gate valves Metering valves Suitable for Chemical industry General industry Variant S6SI with Food certification EG 1935:2004 in accordance with EU 10/2011 FDA conformity Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on 5 kg spool Special...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High strength ePTFE-Graphite Characteristics Extrusion resistant even with large clearances Form stable, wear resistant, heat conductive and can be used as bull ring Shaft protecting (recommended surface hardness: HRC 25) In high pressure applications die formed rings are recommended Operating range Pressure [p max]: 30 bar, Velocity [v max]: 8 m/s Pressure [p max]: 800 bar, Velocity [v max]: 3 m/s Pressure [p max]: 500 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.35 g/cm³ Main application High pressure plunger- and dosing pumps Bullrings for mixers, highpressure valves agitators, gate valves and valves Suitable for Chemical industry Petrochemical plants High pressure machine constructions Approvals BAM for liquid and gaseous oxygen 60 °C/15 bar, 40 °C/65 bar, 200 °C/50 bar Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre-compressed ring-set made of expanded graphite and reinforcement to protect against extrusion Characteristics Packingset made by combining two expanded Graphite grades and designs in order to avoid blow out and extrusion and as well enhance the sealability of this valve sealing set. The set was tested and approved by the AMTEC GmbH Lauffen in Germany. The leakage parameters of 8.6 x 10-3 mbar · l/(s·m) complies with the VDI 2440 at +400 °C, which specifies a maximum allowed leakage of 1.0 x 10 -2 mbar · l/(s·m) (test media helium) and is therefore recommended as a high grade seal system. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 160 [bar] Temperature without LiveLoading: t 400 °C Temperature with LiveLoading: t 400 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Suitable for Power plant technology Chemical industry Petrochemical plants Boiler houses Refineries Approvals TA Luft / VDI 2440 Certificate

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

HT/S Advantage™ / PolarExtreme Reman Fan Drives & HT Now there's a superior alternative to upgrading an HT/S Advantage or S Fan Drive that endures the harshest environments: PolarExtreme Repair Kits. PolarExtreme Repair Kits feature seal components constructed from hydrogenated buna nitrile rubber (HBNR) to enhance the Horton fan drive for extreme conditions. The PolarExtreme super Kit includes the new PFD (Piston Friction Disc) with a unique fin design for better heat dissipation. These kits mean PolarExtreme delivers the ultimate upgrade with: - Longer life - Better abrasion resistance - 30% greater tolerance to temperature extremes - Less likely to suffer spiral fatigue - Less breakage and leakage Horton blue seals identify these kits as the extreme performer — PolarExtreme. PolarExtreme Seal Kit Repairs and upgrades Horton HT/S Advantage and S Air-Engaged Fan Drives Blue D- & O-ring, cartridge assembly, face seal assembly, System Sentry®, umbrella check valve, spline lubricant, spline lubricant brush, socket head screws. PolarExtreme Super Kit Repairs and upgrades Horton HT/S Advantage Air-Engaged Fan Drives PolarExtreme PFD (Piston Friction Disc) with a unique fin design for better heat dissipation, hub assembly, sheave bearings, friction facing, lock nut, blue PolarExtreme D- & O-ring, cartridge assembly, face seal assembly, System Sentry, umbrella check valve, spline lubricant, spline lubricant brush, socket head screws. Related Products - HT/S Advantage Air-Engaged Fan Drives - Advantage Reman Fan Drives & Genuine Horton Repair Kits Links - Order or View Literature - On-line Catalog

Request for a quote

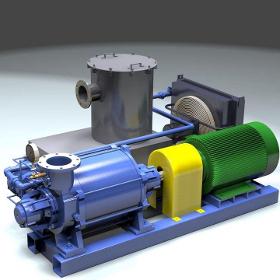

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quoteResults for

Seal systems - Import exportNumber of results

23 ProductsCompany type