- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- screws for plastics

Results for

Screws for plastics - Import export

SPIROL

Germany

SPIROL's FH400 Headed Barbed Pin has a series of barbs extending down the entire length of the pin. Headed Barbed Pins are a great replacement for self-tapping screws in plastic assemblies as Barbed Pins are installed into standard moulded (or drilled) holes, they install much faster than screws, and they eliminate issues associated with cross-threaded or skewing during installation. Unlike screws that resist back-out (or loosening) by being tightened to a preset torque, Barbed Pins are retained by the plastic backfilling over the aggressively-designed barbs. The head provides a positive stop and is also used to retain a thin component to a thicker component within an assembly. SPIROL's FH400 Headed Barbed Pins are available in metric diameters ranging from Ø2mm to Ø6mm and inch diameters ranging from Ø.078" (5/64) to Ø.250" (1/4) in low carbon steel and austenitic stainless steel.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

OKS 1105 prevents the formation of electrically conductive layers and minimises the risk of flashovers and dielectric losses. The insulators and switchgear covered with the paste thus maintain a good insulation resistance. Sealing lubrication for electrical or electronic equipment such as relays, plug-in connections, cable lugs and lamp sockets Protection of insulators and switchgear in humid atmospheres, for example of junction boxes, screw terminals, overload cutouts at high-voltage pylons, connecting cables and terminal connections Lubricant for plastic screw connections and other moving parts of metal, ceramic, plastic Advantages and benefits Excellent water repellent properties Excellent surface wetting Good adhesion on glass, porcelain and plastics Stable consistency across a wide temperature range Very good resistance to chemical and weather-based influences (e.g. ozone, UV radiation) Neutral with regard to many materials

Request for a quote

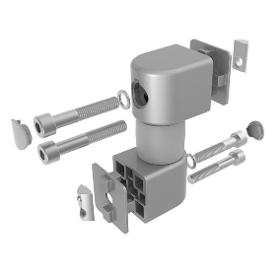

FATH GMBH

Germany

Description: Connection joint with friction for the creation of system arms using profile pieces; pivotable 360°; friction joint can be attached lateral, transverse, or on the face of the profile; if attached on the front face, the core hole of the respective profile must be M8 threaded (min. 15 mm deep) Material: Housing: Aluminum die-cast Cover ring: Plastic Inserts: Steel Friction shaft: Steel Cover caps: Plastic Screws: Steel Washers: Steel Centering plates: Aluminum die-cast T-slot nuts: Steel Surface: Housing: Laquered Centering plates: Laquered Screws: Zinc plated Washers: Zinc plated T-slot nuts: Zinc plated Color: Housing: Alu color Cover ring: Gray ≈ RAL 7042 Cover caps: Gray ≈ RAL 7042 Centering plates: Alu color Set: Various Sets available - Please contact us for Details Pack Quantity: 1 piece/set

Request for a quote

HEXPOL TPE GMBH

Germany

In the extrusion process the TPE pellets are poured into a hopper are heated in the barrel and turned into a melt by this heat and shear. A screw carries the melted plastic through a shaped die to produce continuous lengths of shapes with the same profile, which are then cooled by air or water. Our TPE compounds are easily extruded into single and complex profiles. They can also be co-extruded with other materials to yield a part with both rigid and soft components. They exhibit improved profile flexibility. The SEBS compounds, with their saturated intermediate blocks, are very stable against thermal degradation. On the other hand, the SBS compounds degrade if overheated or if a screw with excessively high compression ratio is used. The information below is intended as a general overview, settings may vary depending on the specific grade selected. Please CONTACT US for detailed processing information SEBS based materials Equipment Extruders used for polyolefines are best for TPE comp

Request for a quote

GAPLAST GMBH

Germany

SOLID Oral Container Closure Systems The preliminary task of each packaging system is to store and protect the content. But at the same time it is also inevitable to match the ease of use when opening and closing the container. Whilst fitting to different designs of container openings, like • snap on (Ø 19,85 mm – 54,50 mm) • screw or different container materials, like • plastic • aluminium • glass the following closure features are available solely or in combination: • tamper-evident • with integrated desiccant • for tablet storage • with distance holder: by an additional bellow or by an integrated spiral • childproof (ISO 8317 & CFR §1700.20) by integrated, self-resetting push-pull slider Senior friendly desiccant stopper with pull tab Unfortunately, a gain in ages usually goes along with a loss in power. Therefore, the target is to engineer an easy to use packaging which also fulfils pharmaceutical requirements. System Benefits (B2B) • Compatible to standard and already in.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Screws for plastics - Import exportNumber of results

5 ProductsCountries

Company type