- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- parts

Results for

Parts - Import export

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatic control valve in flange design. The integrated positioner Type 8049 offers a compact design. All wetted parts are made of stainless steel. Flanges acc. DIN EN 10921 Flanges acc. ANSI #150 Digital positioner type 8049 Pneumatic and electropneumatic positioner type 8047 Positioner with integrated process controller type 8049 IPC Positioner type 8047 and type 8049 also in explosionproof version Piston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuator Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mould parting agent for entire range of plastics processing if an adhesion-dependent further processing requiring silicone-free parting agent is carried out Welding parting agent for arc welding and inert-gas arc welding As nozzle spray for extended service life of welding nozzle and keeping nozzle opening clear on automatic welding units As workpiece protection against baking and burning on of weld spatters Advantages and benefits Silicone free release agent with high effective substances from renewable primary products Prevents from burning in of spatters at welding nozzles, on workpieces and robots and increases the lifetime of the welding torch Builts up an evenly thin, nearly dry film, no creation of pores Enables the fast change and cleaning of the welding nozzle Easily washable with OKS 2650 Additional painting, metallising and printing after prior degreasing without any difficulties possible

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences MOSH/MOAH-free NSF H1-registered

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAUP GMBH & CO KG

Germany

Forklift truck attachments, stationary equipment for material handling and container spreaders from KAUP are known for their ease of use. Because the user-oriented design makes it possible for it to fulfil its intended use for years. That notwithstanding, it is normal that even KAUP products are subject to more or less heavy wear, depending on use. That can lead to delays in normal operations and even to breakdowns. In order, however, to keep the downtime of an attachment, a stationary equipment for material handling or a container spreader as short as possible in this case, there is the qualified customer service from KAUP. Because, it doesn't matter whether it is replacement parts for an attachment, professional technicians for repair and maintenance, training for regular care or continual maintenance of the KAUP products: the more than 60 employees in customer service at KAUP are the professional contact for every user.

Request for a quote

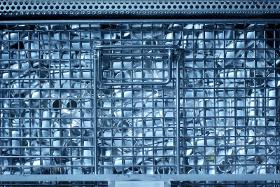

PERO AG

Germany

The R0 has been specifically designed for intermediate and final cleaning of small and extra small parts. Thanks to its universal process technology, the R0 offers operators unrivalled cleaning performance in an extra compact machine. The R0 can be transported through door clearances of as little as 1,000 x 2,000 mm. Depending on the model, the cleaning unit can be loaded from the long or from the short side. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Top quality cleaning in compact unit Short cycle times High throughput Available as 1 and 2bath unit with loading of the unit via Manual charging unit Automatic charging unit

Request for a quote

PERO AG

Germany

After cleaning, parts are normally dried. Efficient drying keeps cleaning medium consumption low, and thus helps protect the environment. In addition, drying effectively prevents recontamination and corrosion. When drying tightly packed or porous parts, drying at atmospheric pressure might not be effective, so that drying under vacuum is the only option.

Request for a quote

PERO AG

Germany

The parts are immersed in the wet medium. Dirt is dissolved from the surface by the heated wet medium. By moving the parts while immersed, cleaning is assisted by a mechanical effect. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quote

PERO AG

Germany

The wet medium is sprayed through nozzles onto the surfaces of the parts. Particles are removed from the parts by kinetic energy, and then washed away. The cleaning result is primarily determined by the position and shape of the nozzles, the spray pressure and the volume of media applied to the parts. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quote

PERO AG

Germany

The ROTIMAT 3U is a universal machine for the cleaning of a wide range of parts. It guarantees maximum technical cleanliness, irrespective of the degree of contamination of the parts. It is equipped with two baths for cleaning, and subsequent iron phosphatising/rinsing, wherby each bath has its own pump cycle. The ROTIMAT 3U can be operated with standard baskets or customised parts carriers. Cleaning with aqueous media (acidic, neutral or alkaline) 660 x 480 x 300 mm 4 x 480 x 320 x 200 mm Spray cleaning for extra demanding applications Catering for wide range of parts Suitable for any cleanliness level from light dirt removal to high technical cleanliness Available as 2bath unit with loading of the unit via Manual loading table Manual charging unit Automatic charging unit

Request for a quote

TANOS GMBH

Germany

Consisting of the systainer® T-Loc I, cover insert, EPP, 5 mm and 3-compartment deep-drawn tray incl. 9 dividers for division into 12 variable compartments Suitable for storing different lengths of screws in the systainer®. Compartment dimensions: L 325 x W 61 x D 64 mm Deep-drawn tray material: recycled PS systainer® material ABS With lid insert, EPP, 5 mm and insert with 3 compartments Incl. 9 dividers for 12 variable compartments

Request for a quote

TANOS GMBH

Germany

Consisting of the systainer® T-Loc I, cover insert, EPP, 5 mm and base insert Incl. removable multicoloured individual boxes: - 1 orange box (L 49 x W 245 x H 71 mm) - 2 red boxes (L 49 x W 49 x H 71 mm) - 7 yellow boxes (L 49 x W 98 x H 71 mm) - 2 blue boxes (L 98 x W 245 x H 71 mm) - 1 green box (L 98 x W 147 x H 71 mm) Ribbing is integrated into the deep-drawn tray to hold boxes in place securely with the cover closed. The Boxensystainer® offers great flexibility for storing small components. The multicoloured boxes and base tray are also available separately Deep-drawn tray material: PE plastic systainer® material: ABS Box material: recycled PS * the orange box must always be placed in the front centre section of the Boxensystainer®, otherwise it will not be possible to close the systainer®.

Request for a quote

TANOS GMBH

Germany

Consisting of the systainer® T-Loc I, cover insert, EPP, 5 mm and 2-compartment deep-drawn tray incl. 6 dividers for division into 8 variable compartments Suitable for storing different lengths of screws in the systainer®. Compartment dimensions: L 325 x W 103 x D 64 mm Weight: 1.68 kg Deep-drawn tray material: recycled PS systainer® material: ABS With lid insert, EPP, 5 mm and insert with 2 compartments Incl. 6 dividers for 8 variable compartments

Request for a quote

TANOS GMBH

Germany

Consisting of the systainer® T-Loc I, cover insert, EPP, 5 mm and universal deep-drawn tray with 12 compartments - 1 compartment L 112 x W 234 x D 67 mm - 2 compartments L 88 x W 88 x D 67 mm - 1 compartment L 88 x W 43 x D 67 mm - 8 compartments L 52 x W 52 x 67 mm Suitable for sorting small components such as screws, nuts, puzzle pieces, etc. Deep-drawn tray material: recycled PS systainer® material: ABS With lid insert, EPP, 5 mm and universal insert with

Request for a quoteResults for

Parts - Import exportNumber of results

16 ProductsCompany type