- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packaging equipment

Results for

Packaging equipment - Import export

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

High-output thermoform packaging machines from MULTIVAC have dominated the market for decades. We continue to set the benchmark with our innovative, high-performance, and resource-saving solutions.

Request for a quote

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

The automatic tray sealers are suitable for industrial use - for packaging food, medical and pharmaceutical products as well as industrial and consumer goods.

Request for a quote

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

As a leading manufacturer of automatic traysealers, we have our customers in mind first and foremost. Each machine is individually designed to meet specific requirements.

Request for a quote

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

MULTIVAC offers a wide portfolio for handling a wide variety of products in the packaging process, which is continuously being expanded.

Request for a quote

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

MULTIVAC is one of the leading manufacturers of reliable, high-performance and versatile labelers and direct web printers.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

With automatic lines for slicing and packing sausage, ham and cheese products, MULTIVAC realizes the optimal connection of slicers to thermoforming packaging machines and traysealers.

Request for a quote

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

The semi-automatic traysealers are suitable for industrial use - for packaging food, medical and pharmaceutical products as well as industrial and consumer goods.

Request for a quote

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

MULTIVAC's machine portfolio is unique in the market - and offers the most economical solution for every requirement in terms of size, performance and functionalities.

Request for a quote

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

Our high-tech equipment starts with the meat tempering of the initial product up to the transfer of the finished portion to the packaging machine.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

The peel force is a critical parameter for every user of Tape & Reel. If the peel force is too low, the cover tape will not stick on the carrier tape properly and the components may fall out of the pockets. A too high peel force will cause costly down times at the pick & place machines. The KT 5000 peel force tester from KTECH is the ideal tool to measure the peel force on your production floor. For measuring, a strip of the carrier tape is loaded into the KT 5000 and the cover tape is attached to the sensor. The constant movement of the carrier tape is done with a sprocket wheel. The movement speed is controlled with an encoder. The design of the KT 5000 guarantees the same peel angle and the same peel point during the whole measurement. Before each run, the KT 5000 is doing a selfcalibration of the sensor. The measured values are transferred to a PC via a serial RS232 interface. A green bar on the screen shows a good result, if the measurement is out of limit, the bar is red.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

The vacuum packgaing machine AZ450ES from AIRZERO is working with a suction nozzle compared to vacuum chamber machines. The main advantages are Since only the bag and not the entire chamber is emptied, the process is faster. Lower gas consumption when gassing (only the bag is gassed and not the entire chamber). The gas is blown into the bag in a targeted and controlled manner. No limitation of the bag length by the chamber. Bar goods can therefore also be processed. Compact standalone device. double sealing (up/down) ejektorvakuum pump (air pressure required) gas flushing vacuum creation timer controlled, sensor controlled digital vakuum display 4 programms can be saved housing of stainless steel suitable for cleanroom

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

In contrast to chamber devices, the vacuum sealer AZ450 from AIRZERO works with a suction nozzle. This principle offers advantages Since only the bag and not the entire chamber is emptied, the process is faster. Lower gas consumption when gassing (only the bag is gassed and not the entire chamber). The gas is blown into the bag in a targeted and controlled manner. No limitation of the bag length by the chamber. Bar goods can therefore also be processed. Compact desktop device. double sealing (up/down) ejektor vakuum pump (air pressure required) gas flushing digital vakuum display 4 programms can be saved housing of stainless steel

Request for a quote

HEXPOL TPE GMBH

Germany

TPE styrene based material in 0 Shore A to 65 Shore D. We have developed a family of materials - the Dryflex S range, which can be used advantageously in most applications. The material is easy to process and is ideal for injection moulding but can also be extruded. We have engineered endless formulations to fulfil different properties and application requirements. Grades with improved compression set properties, high temperature or abrasion resistance. Here we give you an introduction to some of our typical grades, contact us to discuss your specific requirements. Applications include: Soft-touch grips & handles Packaging caps & closures Sports equipment Toys & infant care Packaging Tools & hardware Automotive components Download the Dryflex S Product Guide Dryflex S 400 Series SBS Based Materials A good alternative for indoor applications and disposable articles that do not have high requirements for ageing and heat resistance. The 400S series covers grades from

Request for a quote

RIDZEWSKI GMBH

Germany

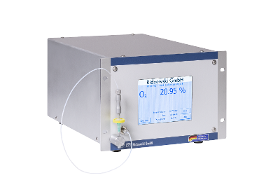

The EPC VM is our measuring device for monitoring O2/CO2 in packaging machines. In addition to continuous measurement of the gas atmosphere, spot measurement of individual packages is also possible. The functionality is the same as with our Zr-Ox EPC spot analyser. Once set, the analyser can also control the gassing of the machine. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels

Request for a quote

RIDZEWSKI GMBH

Germany

The Zr-Ox EPC is our standard model for continuous monitoring of residual oxygen. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels - Standardised 0/2-5/10 VDC or 00/04-20 mA analogue signal adjustable - 3 backups for storing different unit functions and settings - Display of all alarms and errors

Request for a quoteResults for

Packaging equipment - Import exportNumber of results

16 ProductsCompany type