- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- measuring machines

Results for

Measuring machines - Import export

MICRO-EPSILON

Germany

Micro-Epsilon tire uniformity and geometry machines measure force variation, runout, and sidewall appearance. Monitoring tire geometry i.e. the measurement of radial or lateral runout as well as side wall detection for bulges, constrictions, dents, week stamp etc., is the most important inspection at the end of the tire production process.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication, cleaning and protection of bright metal surfaces, e.g. of precision machine tools, measuring equipment, mechanisms in precision mechanics and optics, of precision instruments Can be used at machine elements of all types, for example sliding parts or slideways, at threads, locks, hinges, joints, drives Versatile use over the full range of care, conservation and maintenance applications Advantages and benefits Highly effective due to good wetting, dissolving and protective ability Good creep properties Behaves neutrally with respect to plastics, elastomers and paints Good protection against corrosion-causing moisture and wetness Resin and acid-free OKS 700 is also suitable for use with the refillable Airspray system Also available as spray version OKS 701

Request for a quote

MICRO-EPSILON

Germany

Optical micrometers from Micro-Epsilon operate according to the transmitted light principle (ThruBeam micrometer). Here, the transmitter produces a parallel light curtain that is transmitted via a lens arrangement into the receiver unit. The beam is interrupted if an object is in the light path. The resulting shadowing is detected by the receiving optics and output as measurement value. Most optical micrometers are used for dimensional measurements in production, machine monitoring and quality assurance. Parameters such as diameter, gap, height and position are detected with high accuracy.

Request for a quote

MICRO-EPSILON

Germany

The reflectCONTROL RCS110-245 with integrated controller is designed for stationary measurements or integration into machines. This compact sensor detects anomalies on shiny surfaces which are processed and displayed as reflectivity and curvature image by software. GigE Vision enables the transfer of surface images to a wide range of image processing software packages for further analyses.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For lubrication points of all kinds as slide ways, spindles, geared parts of the electronic, precision engineering and optical equipment, temporarily or permanently exposed to extreme low temperatures like in arctic climates or cold storages Roller bearing lubrication of high-speed bearings, e.g. spindle bearings, miniature or precision bearings in machine-tools or textile machines, measuring equipment, electric motors of control technology and precision mechanics Advantages and benefits Dynamic light noise proofed long-term lubrication grease Best use at arctic conditions and very high speed High efficiency through optimal formulation Multifunctional application beside the regular range of performance for greases Efficient through economical application No nameable change of consistency at low temperatures or high speeds and accordingly temperatures

Request for a quote

VOXELJET AG

Germany

Our international bestseller: the VX1000 is a universal 3D printer for industrial applications. The machine is fast, easy to operate and enables you to cost-effectively produce medium-sized molds, cores and models for making prototypes. The VX1000 is also suitable for producing small series. Plastic and sand can be used as the particulate material. The piezo print head system of the VX1000 achieves a resolution of up to 600 dpi. The machine's build space measures 1,000 x 600 x 500 mm. The thickness of a layer applied in one cycle is 150 µm for plastic and 300 µm for sand. In addition, the VX1000 concept is environmentally friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quote

VOXELJET AG

Germany

The VX500 is a 3D printer for industrial applications that has been tried and tested many times over in practice. These machines can be found wherever there is a demand for the straightforward production of prototypes and models. Despite their compact dimensions, they captivate with the features of a high-performance printer, such as multi-jet print heads, integrated material handling and job boxes. The machine is very fast, easy to operate and permits cost-effective production of both individual parts and small series alike. Plastic can be used as the particulate material. The machine's build space measures 500 x 400 x 300 mm. The VX500's print head system can achieve a resolution of up to 600 dpi. The thickness of a layer applied in one cycle is 150 µm. In addition, the VX500 concept is resource-friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quote

MICRO-EPSILON

Germany

mainSENSOR is based on an innovative measuring principle, which has been developed by Micro-Epsilon in order to combine the advantages of both inductive and magnetic sensors. Magneto-inductive sensors are frequently used as alternative to inductive sensors and proximity sensors in process automation, the packaging industry and in machine monitoring. Measuring the distance to a magnet which is fixed at the measurement object, the sensor outputs a continuous, linear signal. As different strength magnets are applied, measuring ranges of between 20 mm and 55 mm can be achieved. However, in order to adapt the measuring range, it is only necessary to change the magnet.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication, cleaning and protection of bright metal surfaces, e.g. of precision machine tools, measuring equipment, mechanisms in precision mechanics and optics, of precision instruments Can be used at machine elements of all types, for example sliding parts or slideways, at threads, locks, hinges, joints, drives Versatile use over the full range of care, conservation and maintenance applications Advantages and benefits Highly effective due to good wetting, dissolving and protective ability Good creep properties Behaves neutrally with respect to plastics, elastomers and paints Good protection against corrosion-causing moisture and wetness Resin and acid-free OKS 700 is also suitable for use with the refillable Airspray system

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Visual Inspection of Surfaces This SE1000 Visual inspection measuring machine has been developed to automatically inspect the appearance of dirt, scratches, and other imperfections on various kinds of surfaces of your product. This 2D inspection technology can be used in production lines and is suitable for all kinds of industries that want to improve quality, reduce human involvement in inspection and reduce inspection time. Leveraging this fast, precise inspection machine will help you to improve the quality of your product dramatically.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

This TM1000 Chain inspection machine has been developed to automatically inspect timing chains. It measures the coordinates of chain pins from the top and bottom surfaces. The machine also measures and quantifies the posture of pins relative to the position. A calibration certificate can be generated.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

HEIDENHAIN angle encoders with integral bearing are characterized in particular by very high system accuracy. The integral bearing in the encoders eliminates any effect on measuring accuracy from the bearing of the machine components. The integrated stator coupling in the RCN/RON/ECN series encoders guarantees lowest possible error from the effect of tolerances in the shaft coupling. All angle encoders with integral bearings feature shaft seals that ensure resistance to contamination (IP64 protection). These encoders enjoy an entire spectrum of possible applications in machine tools, measuring machines, telescopes, printing machines and many other areas. Absolute measuring method Hollow shaft diameter (up to 50 mm) Integrated stator coupling Simple installation Typical field of application: Rotational axes with reduced accuracy requirements

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

HEIDENHAIN angle encoders with integral bearing are characterized in particular by very high system accuracy. The integral bearing in the encoders eliminates any effect on measuring accuracy from the bearing of the machine components. The integrated stator coupling in the RCN/RON/ECN series encoders guarantees lowest possible error from the effect of tolerances in the shaft coupling. All angle encoders with integral bearings feature shaft seals that ensure resistance to contamination (IP64 protection). These encoders enjoy an entire spectrum of possible applications in machine tools, measuring machines, telescopes, printing machines and many other areas. Incremental measuring method Large hollow shaft diameter (up to 60 mm) Integrated stator coupling Compact size for limited installation space System accuracy includes the deviation caused by the shaft connection Outstanding dynamic response Simple installation Typical field of application: Rotary tables Swivel heads

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

Sensors and accessories for vibration measurement and Condition Monitoring Large selection of vibration sensors accelerometers, displacement sensors, VIBCODE transducer and triaxial sensors Accelerometers measure vibration acceleration, shock pulse (roller bearing condition) and pump cavitation Also available in compact size, for lowspeed machines and as combi sensors for vibration and temperature Patented tandempiezo technology eliminates the disadvantages of conventional sensors Highquality signal transmission over long distances up to 1,000 meters (3,200 feet) with current line drive (CLD) signal amplification Various mounting types EX / ATEX versions available Temperature probes, keyphasers, cables, adaptors and tools available

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

A major hallmark of HEIDENHAIN angle encoders is their very high system accuracy. This makes them particularly advantageous in demanding applications for machine tools, measuring machines, telescopes, printing machines, etc. Because the bearing is integrated into the encoder, machine component bearings have no effect on the measuring accuracy.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

A major hallmark of HEIDENHAIN angle encoders is their very high system accuracy. This makes them particularly advantageous in demanding applications for machine tools, measuring machines, telescopes, printing machines, etc. Because the bearing is integrated into the encoder, machine component bearings have no effect on the measuring accuracy.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Exposed linear encoders are designed for use on machines and installations that require high accuracy of the measured value. Typical applications include: Measuring and production equipment in the semiconductor industry PCB assembly machines Ultra-precision machines High-accuracy machine tools Measuring machines and comparators, measuring microscopes, and other precision measuring devices Direct drives Our standard encoders are suitable for use in a low or medium vacuum. Encoders used for applications in a high or ultrahigh vacuum need to fulfill special requirements. Design and materials used have to be specially adapted for it. For more information, refer to the Technical Information document Linear Encoders for Vacuum Technology. The following exposed linear encoders are specially adapted for use in high and ultrahigh vacuum environments. • High vacuum: LIP 481 V and LIF 481 V • High vacuum: LIC 4113 V and LIC 4193 V • Ultrahigh vacuum: LIP 481 U

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DR. JOHANNES HEIDENHAIN GMBH

Germany

The GAGE-CHEK 2000 evaluation unit is particularly well suited for positioning tasks on measuring devices and positioning equipment, and for the retrofitting of measuring machines for the capture and transfer of data to a PC. Design Thanks to its rugged industrial design, the GAGE-CHEK 2000 is superbly suited for applications in measuring rooms as well as in harsh production environments. Its slim aluminum housing with integrated power adapter and fanless passive cooling system is exceptionally sturdy and resilient. The unit’s straightforward touchscreen, made of specially hardened glass, supports multitouch gesture control and permits operation with gloves.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

Safe, simple, precise The new VibScanner 2 Ex is a nextgeneration, explosion protection system for quickly detecting machine vibration in hazardous work environments. Measuring simultaneously on three axes, the VibScanner 2 Ex sets the benchmark for fast and accurate measurements of machine, gear, and bearing issues. This is the ultimate tool for fast and accurate machine vibration measurements. The VibScanner 2 Ex heightens efficiency and data quality. In just a quarter of the time of a standard datacollector, it precisely measures available data in three axes. Equipped with a triaxial sensor, it requires only one measurement point and the click of a button to begin collecting machine data. This device is ideal for routebased maintenance jobs in environments where explosion protection standards are required. Its rugged magnetic foot of the triaxial sensor fits perfectly on the housing of any motor, pump, fan, or other rotating device, detecting vibration right near the source.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

A unique handheld measuring device with which even untrained personnel can easily and effectively measure machine vibration on rotating machinery. Thanks to its forwardlooking measuring principle and data acquisition across three axes with the triaxial sensor, all relevant condition information is recorded with the touch of a single button. And at a measurement speed that opens up fully new dimensions. Not only is the VIBSCANNER 2 a breakthrough in terms of measurement speed and precision, but also through its robustness and its intuitive operating concept. The intuitive graphical user interface assists the employee en route in taking repeatable errorfree measurements. The device provides him/her with the exact information about the status of the measurement locations and the progress of the route.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The TS workpiece touch probes from HEIDENHAIN help you perform setup, measuring and inspection functions directly on the machine tool. The stylus of a TS touch trigger probe is defl ected upon contact with a workpiece surface. At that moment the TS generates a trigger signal that is transmitted either by cable, an infrared or radio beam to the control. The control simultaneously saves the actual position values as measured by the machine axis encoders, and uses this information for further processing.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

The mobile solution for machinery health monitoring The VIBXPERT II from PRUFTECHNIK is the mobile power package for fast and reliable recording and analysis of machine condition data. After a very short measuring time, the current machine status data is shown on the color display. The maintenance expert can analyze the data on site. From the recorded machine condition data, all values can be read from the various characteristic value modes that are important for an exact machine condition analysis. The device is used directly on site at the machine, from the machine hall to the diesel generator of an oil tanker or from a bucket excavator to a hydroelectric turbine. The robust design enables both fast and complex interventions. Whether in clinically clean systems, or harsh industrial environments. VIBXPERT II sets the standard in mobile machine and plant condition monitoring.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

Advanced laser shaft alignment in EX/ATEX areas ROTALIGN touch EX is Zone 1 ATEX/IECEX certified. Packed with userfriendly alignment features unique to PRUFTECHNIK, the ROTALIGN touch EX shortens the measurement time with Continuous SWEEP Mode for highquality measurement in only one shaft rotation Live Move function for simultaneous realtime machine corrections in both horizontal and vertical directions vertiSWEEP to measure vertical machines in one rotation of the shaft Cardan shaft rotatingarm bracket allows measurements to be performed without removing the shaft Soft Foot Wizard to diagnose soft foot problems Move Simulator lets the operator simulate shim values and horizontal corrections before moving the machine Have instant access to the critical data you need with full mobile connectivity.

Request for a quote

RIDZEWSKI GMBH

Germany

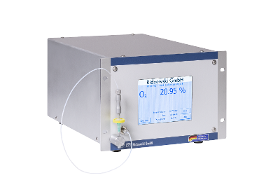

The EPC VM is our measuring device for monitoring O2/CO2 in packaging machines. In addition to continuous measurement of the gas atmosphere, spot measurement of individual packages is also possible. The functionality is the same as with our Zr-Ox EPC spot analyser. Once set, the analyser can also control the gassing of the machine. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels

Request for a quoteResults for

Measuring machines - Import exportNumber of results

25 ProductsCompany type