- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- manufacturing lubricants

Results for

Manufacturing lubricants - Import export

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of friction and rolling bearings, chains, joints or slideways at higher temperatures For conveying systems under radiation heat in painting, stoving and drying systems, travelling grates in firing systems Dry lubrication at temperatures above 200°C Lubrication of elastomers and plastics not resistant to mineral oil Advantages and benefits Highly suitable as a high-temperature lubricant Very effective due to finest, homogeneous MoS₂ distribution in the oil Resistant to water and many chemicals, fuels, lubricants and hydraulic oils For best adhesion, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610/OKS 2611 universal cleaner. With a brush, drip oiler or by immersion or using a suitable automatic lubrication system, apply a sufficient quantity to the locations to be lubricated. If at all possible, avoid excess. Observe the machine manufacturer's instructions. Assess the lubrication frequency

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of valve seals, collars, O-rings, drives, piston rods and guides Lubrication of slides, slat-band and roller chains Lubrication of cutting knives as well as of needles and lifters of knitting machines Dismantling of rusted-in parts and removal of oil and greasy soiling Advantages and benefits NSF H1 registered Highly effective due to good creep properties Broad range of uses Displaces water Duolabel Clean the surfaces for optimal effect. Apply OKS 370 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system locations to be lubricated. Spray on evenly OKS 371 spray. Avoid excesses. In as far as available, observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on the basis of the service conditions. Caution: Only mix with suitable lubricants.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of valve seals, collars, O-rings, drives, piston rods and guides Lubrication of slides, slat-band and roller chains Lubrication of cutting knives as well as of needles and lifters of knitting machines Dismantling of rusted-in parts and removal of oil and greasy soiling Advantages and benefits NSF H1 registered Highly effective due to good creep properties Broad range of uses Displaces water OKS 370 is suitable for use with the OKS Airspray system Also available as spray version OKS 371 Clean the surfaces for optimal effect. Apply OKS 370 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system locations to be lubricated. Spray on evenly OKS 371 spray. Avoid excesses. In as far as available, observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on the basis of the service conditions. Caution: Only mix with suitable lubricants.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, hinges, joints, clamping and drying frames or slideways at higher temperatures Suitable for conveying systems in painting, stoving, drying and cooling bed installations Advantages and benefits Highly effective due to optimum wear protection and outstanding oxidation properties Resistant to water and steam Good creep properties Very good adhesion and lubrication effect with no tendency to drip Also available as spray version OKS 3521 For optimum effect, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 352 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system to locations to be lubricated. Spray OKS 3521 on evenly. Allow excess to drip off and wait for lubricant to penetrate before resuming operation. Observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on basis of service conditions

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, fringe bearings, hinges, joints, clamping and drying frames or slideways at higher temperatures and loads For conveying systems under radiation heat in painting, stoving and drying systems Advantages and benefits Highly effective due to finest, homogeneous MoS₂ distribution in the oil Emergency running properties through MoS₂ at dry running Outstanding adhesion and lubrication effect with no tendency to drip or dry out Silicone-free For best adhesion, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. With a brush, drip oiler or by immersion or using a suitable automatic lubrication system, apply a sufficient quantity to the locations to be lubricated. Allow excess to drip off. Allow OKS 350 to soak in before operating. Observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on basis of service conditions

Request for a quote

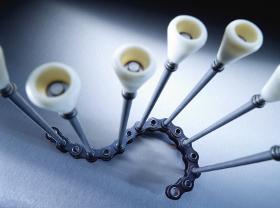

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Highlights • iwis high precision roller chains: long-lasting, reliable, excellent wear resistance • Special lubrication for can manufacturing: non-drip, high temperature range, approved for use in the food industry • Protection heads: high-temperature and high-performance material. Standard type available, other geometries and materials on request. • Length of transport pins can be adapted to customer specifications • Predefined fracturing points in the pins prevent damage within the lines in case of collision (POChain-P/-S) • Transport pins: easily changed on-site without damaging the chain or removing it from the machine (POChain-P/-S)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Manufacturing lubricants - Import exportNumber of results

6 ProductsCountries

Company type