- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- testing

Results for

Testing - Import export

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The NTS is designed for testing and servicing fuel injectors of large diesel engines. Use NTS for examining the spray pattern, for leak testing of the needle seating and for. Features The infinitely adjustable testing pressure is is generated by means of an air powered double acting high pressure pump. The attachment for clamping the fuel injector is of rigid design and swivel-mounted so that the injector can be turned to horizontal position for ease of servicing. The transparent container for collecting the testing liquid is provided with an outlet for removing the liquid by suction.

Request for a quote

HOCHRAINER GMBH

Germany

Test station for foot-activated parking brake

Request for a quote

MICRO-EPSILON

Germany

The capaNCDT DT61x4 is an active, capacitive system for displacement, distance and position measurements. Consisting of a sensor with integrated preamplifier, a robust cable and a compact controller, the measuring system is immediately ready for use without any on-site calibration. The measuring system is available with a cable length up to 15 m and is ideal for automation purposes. The capaNCDT 61x4 is particularly suitable for automated robot manufacturing and measurement tasks with a drag chain. Moreover, it is used in machine building and semiconductor production. For optimum signal quality, the desired cable length is already factory-calibrated.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

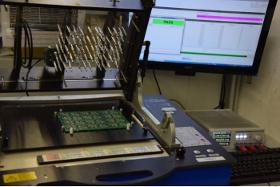

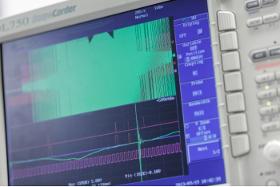

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. PRUFREX is a manufacturer of test systems and software. In close collaboration with our own test equipment developers, we manufacture beds of nails for the in-circuit test (ICT) and functional test (FCT), alongside test equipment and production aids. Using the entire range of available test procedures, we will develop a strategy that suits your product.

Request for a quote

MICRO-EPSILON

Germany

3D sensors from Micro-Epsilon are equipped with an easy-to-integrate SDK (Software Development Kit). The SDK is based on the GigE Vision and GenICam industry standards including the following function blocks: Network configuration and sensor connection Extensive sensor control Transmission control of measurement images Management of user-defined parameter sets C++ sample programs and documentation Access to the sensor via GigE Vision is also possible without SDK using a GenICam client.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. When planning tests, we work to your test specifications or develop a cost-optimised, efficient concept. In our tests, we simulate real usage conditions. In this way, we make sure that devices, systems or components will function correctly. Quality management at PRUFREX also includes developing efficient testing strategies.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

We consider the future test strategy in the design phase and implement it in parallel with production. Among other things, during the development phase, we think ahead to consider the test contacts for the test fixture. An ICT test without test contacts is also possible. Our forethought helps to avoid the need for expensive corrections or additional production steps.

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

Vibrating tables suitable for testing and quality inspection of sensitive components The vibratingsystems are employed for simulation of stress created by mechanic vibrations on mechanical and electrical components and subassemblies with the following features: Direction of oscillation: linear - horizontal (sinusoidal oscillation), adjustable by means of a selector. Either oscillation in x-axis or alternatively in y-axis

Request for a quote

PERO AG

Germany

Bring your dirty parts to the PERO Centre of Competence. The cleaning experts of PERO will advise you in how these parts can best be cleaned. You can then perform a series of tests in order to identify the optimised cleaning process for your parts. Cleaning tests free of charge, using your own parts; including documentation Evaluation of cleanliness analyses Gaining new insights into own cleaning processes

Request for a quote

PERO AG

Germany

PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. In manufacturing plants, parts cleaning is one of the key activities along the production line. The productivity of a manufacturing plant is determined by the availability of the cleaning technology. At the PERO Centre of Competence, PERO specialists work together with operators to develop the cleaning method that best suits their needs.

Request for a quote

PERO AG

Germany

At the PERO laboratory for technical cleanliness that forms part of our Centre of Competence, we analyse and assess the outcomes of the cleaning tests. Analytical lab, vacuum drying unit, testing instruments Examination under light microscope Assessment of cleanliness analyses according to VDA 19 and other standards

Request for a quote

AFS ENTWICKLUNGS + VERTRIEBS GMBH

Germany

Measurement of the surface tension The adhesion of a surface is usually directly dependent on the surface energy. If the surface energy is substantially lower than that of the printing ink used, the wetting is disturbed, resulting in poor adhesion. For this reason, plastic surfaces have to be pre-treated. Depending on the type of ink used the surface tension required can vary: solvent based inks => 38 bis 42 mN/m (=Dyn/cm) water soluble inks => 40 bis 44 mN/m UV inks => 44 bis 46 mN/m With the test inks of AFS, which are available from 34 to 56 dyn/cm surface tensions of plastic films can be easily and reproducibly determined according to DIN ISO 8296. Depending on whether the ink sticks or bubbles on the surface it indicated whether the surface tension is above or below the dyne-value of the currently used test ink. We also offer the test inks in a case with 12 bottles from 34 to 56 dyn/cm.

Request for a quoteResults for

Testing - Import exportNumber of results

13 ProductsCompany type