- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plastic materials

Results for

Plastic materials - Import export

MESUTRONIC GMBH

Germany

metal separator was developed for the examination of plastic granulates, ground material and powders for metallic foreign bodies. It is used in the injection molding and extrusion areas for slow-flowing material columns. Both the detector and the ejection unit have been specially developed for this area of use. This results in top performance data for precision, operating reliability and ease of cleaning. Failsafe storage of all system parameters Digital signal processing for best detection Process- and condition monitoring Standardised system for a wide area of use Robust construction for maximum lifetime Highest precision in long-term operation Fast ejector for minimized material loss Dismantle without tools All components are easily accessible

Request for a quote

MESUTRONIC GMBH

Germany

- detects and separates any type of metal, loose or encapsulated - flexible integration into existing conveying systems independent of direction, quick and cost-effective -easy to operate - high-precision metal detection, extremely reliable - uncompromising safety, thanks to mesuSafetyPack

Request for a quote

SYSKOMP GMBH - EMICO

Germany

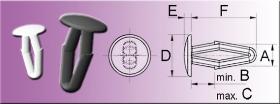

Unique: One rivet for several sheet thicknesses. Quick and easy to assemble by hand. Made of a plastic material with lasting elasticity. Material: POM Colours: last digits 000 = white last digits 599 = black Further types on written request.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® ECO is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The ECO series is the basic model of the OKTOMAT® emptying stations and is ideally suited for the majority of applications dealing with free-flowing to poorly flowable materials. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable. Due to its pedestal form, the ECO is particularly space-saving in width, the height is individually adjustable.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® SOS is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its pedestal form, the OKTOMAT® SOS is particularly space-saving in width, the height is individually adjustable. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® SOS is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its pedestal form, the OKTOMAT® SOS is particularly space-saving in width, the height is individually adjustable. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

The HELIO®MAT dryer station is part of the JETBOXX® system and features an independent JETBOXX® dryer with full functionality at each individual docking station. The material can be predried in removable drying containers at the dryer station. The drying container can be removed and brought to the processing machine if needed. It will be attached directly onto the feeding section there and the dried material can be processed. If the material should be kept dry on the machine, a JETBOXX® docking plate with dryer control are used in addition. HELIO®MAT is applicable for example as pre-drying station for quick material change, as dryer station for sampling batches, for batch drying for small quantities / sampling, for laboratory applications, or for cleanroom supply with hermetically sealed dry material containers. Material change without delay. No humidification. No cleaning issues.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

The JETBOXX® mini top-mounted dryers are particularly applicable where small material flow rates with the highest drying precision are required. Due to their compact design, the plastic granulate dryers can be mounted on the feed section of the injection molding machine without any difficulty. The dryers are available with a volume of 0,5/1,0/2,5/5/6/12/18 litres and can be optimally adapted to your requirements with a large number of options from the JETBOXX® system. Compressed air conveyors of one or two components with or without dedusting function are available. Filling by hand is also possible via hinged covers. The compressed air-based dryers are maintenance-free and provide professional functions such as: plastic-specific and throughput dependent dryer settings, database for plastics, conveying control, week timer, overheating protection, dew point measurement, speed dial programs, personal programs, and many more.

Request for a quote

PPS GMBH

Germany

The Standard Plastic card is heat proof up to about 60°C. For most applications this is sufficient. There are special demands where a much higher heat proof is needed, such as use of cards in hot regions or especially in the car behind the windshield. Special HT material can resist high temperatures up to 110°C. Because of the characteristics of the material also higher resistance against breaking and more flexural stiffness. We are happy to answer your questions - Give us a call! Or use the inquiry form Examples of application: Standard quality and Type: 0,76 mm PVC laminated, heat proof up to 70°C in Offsetprint CMYK Quality and Type 0,76 mm PVC laminated (Credit card quality) 0,76 mm PVC High temperature up to 85° C 0,76 mm PVC High temperature up to 100° C 0,6 mm PVC varnished 0,5 mm PVC laminated 0,4 mm secure cardboard varnished 0,3 mm PVC varnished

Results for

Plastic materials - Import exportNumber of results

10 ProductsCompany type