- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plain bearings

Results for

Plain bearings - Import export

GLT BEARINGS GMBH

Germany

Spherical plain bearings are machine elements that can be installed immediately and are produced according to a specific standard. Since they are plain bearings, there is sliding contact between the inner and outer ring. Spherical plain bearings are ideal for rotary, tilting and swivelling movements and are insensitive to shocks, impacts and vibrations. This makes them extremely popular for load-bearing and guiding functions. You will find both maintenance-free and maintenance-required spherical plain bearings in our product range. Our maintenance-free spherical plain bearings comply with DIN ISO 12240-1, dimensional series E/G. The sliding pairing consists of a hard chrome/PTFE composite. The bearings themselves are manufactured with the tolerance group CN. These are also available in sealed versions. If you require additional dimensions or unique designs, please let us know in an enquiry form, and we will supply you with the desired product.

Request for a quote

GLT BEARINGS GMBH

Germany

Sintered bronze plain bearings | Maintenance-free | Oil-impregnated | Self-lubricating | DIN 1850 / ISO 2795 SIB-MET® is a self-lubricating and maintenance-free plain bearing. Suitable for high speeds at low loads. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Solid bronze plain bearing | Maintenance-free | With solid lubricant deposits in the sliding surface | Version available with water-resistant solid lubricant LUB-MET® is a maintenance-free plain bearing. However, initial lubrication is necessary. For high loads, shock loads, wear-resistant, insensitive to dirt, corrosion-resistant, long service life. For technical details, please visit the product page on our website!v

Request for a quote

GLT BEARINGS GMBH

Germany

Machined bronze plain bearing | Requires maintenance | DIN 1850 / ISO 4379 BRO-MAS® is a plain bearing requiring maintenance, is suitable for operation in contaminated environments, has good corrosion resistance, and is insensitive to shock loads. Oil or grease lubrication is needed. Additional lubrication grooves or holes significantly reduce relubrication intervals and improve lubricant distribution. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Rolled composite plain bearing | Maintenance-free | Steel / graphite bronze | With embedded solid lubricants GAP-MET®/S is a maintenance-free composite plain bearing. However, oil or grease lubrication is possible. High load capacity and strength, for all slow movement types, suitable for contaminated environments, no moisture absorption, good chemical resistance. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Thermoplastic all-plastic plain bearing | Maintenance-free COM-KU®/X is a self-lubricating and maintenance-free plastic plain bearing made of a high-quality plastic compound with the best sliding properties. Excellent tribological properties, especially for dry running. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped spring steel plain bearing | Requires maintenance | DIN 1498 | DIN 1499 FER-MET® is a spring steel plain bearing without integrated sliding material. Lubrication of the bearing point is necessary. Very high load capacity and impact resistance for heavy-loaded applications with impact loads. Very wear-resistant. A standard gap design with a straight slot and without chamfer inside [EG], but can also be manufactured with other slot shapes if required. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Fibre-reinforced compound plain bearing in wound technology | Maintenance-free | High load capacity COM-KU®/D is a self-lubricating and maintenance-free compound plain bearing. It has good sliding properties and is suitable for loads (also impact loads and with edge pressures). Good damping properties, very suitable for low sliding speeds, good chemical resistance, and long service life. Suitable as a replacement for lubricated bearings. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Solid, turned, grinded and hardened steel plain bearing | Requires maintenance FER-MAS® is a steel plain bearing without integrated sliding material. Good lubrication is required! Suitable for highest loads, insensitive, long service life. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

COM-KU®/S is a self-lubricating and maintenance-free plastic plain bearing. However, additional lubrication is possible. It is well suited for simple applications and axial movements

Request for a quote

GLT BEARINGS GMBH

Germany

Rolled composite plain bearing steel / PTFE coated | Maintenance-free dry plain bearing | DIN 1494 / ISO 3547 TEF-MET is a versatile dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, additional lubrication is possible in principle! For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Rolled composite plain bearing steel / PTFE coated | Maintenance-free dry plain bearing | DIN 1494 / ISO 3547 TEF-MET/B is a versatile, corrosion-resistant dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, additional lubrication is possible in principle! For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing with lubrication pockets/ copper-plated steel & CuSn10Pb10 & graphite | maintenance-free | DIN 1494 / ISO 3547 BIV-LUB® is a maintenance-free composite plain bearing with solid lubricant depots. Initial lubrication is necessary! High load capacity with low wear, very suitable for low sliding speeds and oscillating movements. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing with lubrication pockets/ CuSn8P & graphite | maintenance-free | DIN 1494 / ISO 3547 BRO-LUB is a maintenance-free bronze plain bearing with solid lubricant depots. Initial lubrication is necessary! High load capacity with low wear, very suitable for low sliding speeds and oscillating movements. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing with lubrication pockets/ copper-plated steel & CuSn10Pb10 | Low-maintenance | DIN 1494 / ISO 3547 BIV-MET® is a low-maintenance bronze plain bearing. However, initial lubrication is required—both oil and grease lubrication are possible. Due to the lubricant depots, the relubrication intervals are greatly reduced! For high loads and oscillating movements as well as for rough operation and temperature load. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped bronze sliding bearing with lubrication holes/ CuSn8P (DIN 17662) | Low-maintenance | DIN 1494 / ISO 3547 BRO-MET®/L is a low-maintenance bronze plain bearing. However, initial lubrication is required—both oil and grease lubrication are possible. The hole depots reduce the relubrication intervals even more! High load capacity and strength with low wear, suitable for rough operation, corrosion resistant. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped bronze sliding bearing with lubrication pockets/ CuSn8P (DIN 17662) | Low-maintenance | DIN 1494 / ISO 3547 BRO-MET® is a low-maintenance bronze plain bearing. However, initial lubrication is required—both oil and grease lubrication are possible. Due to the lubricant depots, relubrication intervals are significantly reduced! High load capacity and strength with low wear, suitable for rough operation, corrosion resistant. For technical details, please visit the product page on our website!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GLT BEARINGS GMBH

Germany

Our rod ends in the best quality for you We manufacture rod ends in various designs for you. You can order these in our online shop in the desired dimensions and with individual adjustments. We will also be happy to supply you with other unique designs at short notice on request. Convince yourself of our more than 40 years of experience in plain bearing technology! Rod ends consist of a housing and a built-in spherical plain bearing. The housing of a screwable rod end has an external or internal thread. Rod ends are particularly suitable for use in linkage and lever connections. In our product range, you will find both maintenance-free and maintenance-bound rod ends. Our special hydraulic rod ends are available either for bolting on or for welding on. Our rod ends are suitable for high static loads. The maintenance-required rod ends can withstand changing loads and impact loads permanently without any problems, while maintenance-free models can only do this to a limited extent.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of rolling and plain bearings subject to very heavy loading Protection of bearings against harmful impurities Protection against corrosion, maintenance of lubricating effect, even when exposed to large quantities of water Advantages and benefits Excellently suited as a high-performance lubricating grease due to special EP properties and solid lubricants The high base oil viscosity, with a stable soap basis even when exposed to water, results in a particular suitability for heavily loaded, slow-running bearings even with impact loading Good emergency running properties due to solid lubricants

Request for a quote

GLT BEARINGS GMBH

Germany

Solid sintered bronze bearing | Maintenance-free | With uniformly embedded solid lubricant in the bronze or iron matrix GAP-MET®/M is a maintenance-free plain bearing. However, oil or grease lubrication is possible. High load capacity and strength for all slow movement types, suitable for contaminated environments, no moisture absorption, good chemical resistance and good temperature resistance. The parts are mechanically reworkable. For technical details, please visit the product page on our website!

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Special grease for the long-term lubrication of ball and plain bearings where electrical charge is possible, e.g. in electric engines, foil- stretching and foil-printing machines, etc. Advantages and benefits Long-term lubrication grease with a wide temperature range and good corrosion protection The special lubricating concept makes sure that electrostatic charges in roller bearing applications are destaticized through the grease, so that local discharges are avoided Proven especially for the lubrication of roller bearings below 1 ampere

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembly paste for press-fitting wheels, shafts, tires or bearings Non-stick primer coat for moving threads, guides and slideways to prevent stick-slip effect, seizing and wear Wearing-in lubrication of highly stressed sliding surfaces such as plain bearings, gearwheels, crankshafts with provision of anti-seizing properties Suitable for non-cutting shaping of the difficult type, such as doming, pressing, embossing while avoiding critical metal contacts and welding Advantages and benefits Immediate effective protection against corrosion, wear and stick-slipping under high stress conditions No pressing onto the sliding surface required Highly effective due to the strong affinity of the MoS₂ for metals Extremely low friction at highest loading capability Increased operational reliability of moving parts due to anti-seizing properties Improved performance due to organic molybdenum complex compounds For optimum adhesion, clean contamination and other lubricants

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mounting paste for press-fitting wheels, shafts, tires or bearings to prevent galling Non-stick primer coat for moving threads, supports, guides and slideways to prevent stick-slip effect Wearing-in lubrication of highly stressed sliding surfaces such as plain bearings, gearwheels, crankshafts with provision of anti-seizing properties In non-cutting shaping of the difficult type, such as doming, pressing, embossing while avoiding critical metal contacts and welding Advantages and benefits Against seizing, wear and stick-slip Highly effective due to the strong affinity of the MoS₂ for metals Extremely low friction at highest loading capability Increased operational reliability of moving parts due to anti-seizing properties Resistant to water, oil, grease, chemicals and hydraulic media Improved performance due to organic molybdenum complex compounds For best adhesion, clean the surfaces from dirt and other lubricants. Best way is to clean mechanically first

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembly paste for press-fitting wheels, shafts, tires or bearings Non-stick primer coat for moving threads, guides and slideways to prevent stick-slip effect, seizing and wear Wearing-in lubrication of highly stressed sliding surfaces such as plain bearings, gearwheels, crankshafts with provision of anti-seizing properties Suitable for non-cutting shaping of the difficult type, such as doming, pressing, embossing while avoiding critical metal contacts and welding Advantages and benefits Immediate effective protection against corrosion, wear and stick-slipping under high stress conditions No pressing onto the sliding surface required Highly effective due to the strong affinity of the MoS₂ for metals Extremely low friction at highest loading capability Increased operational reliability of moving parts due to anti-seizing properties Improved performance due to organic molybdenum complex compounds Also available as spray version OKS 221 For optimum adhesion, clean contamination

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For the long time- or for lifetime- lubrication of fast running roller and plain bearings as well as linear guides, threaded and ball screw spindles, small gears and similar components, exposed to high pressures and higher temperatures Advantages and benefits Good adhesive and good media resistant Good low-temperature behaviour, stress absorbing ability and smooth run at high speeds Good plastic compatibility The low start and running moment, especially at low temperatures, enables a high efficiency The good wear protection increases the life time of the part and makes sure a reliable functionFor best results clean the lubrication point with OKS 2610/OKS 2611 Universal Cleaner. Remove the corrosion protection media before initial filling. Fill the bearings in a way that all the functional surfaces are lubricated sufficiently. Slow moving bearings (DN-value < 50,000) should be filled completely. Fast running bearings (DN-value >400,000) should be filled

Request for a quote

MICRO-EPSILON

Germany

The compact DTD inductive sensor system consists of a gauge with a plunger guided by a plain bearing and a controller, which are connected to each other with a 3 m long cable. The controller has a diameter of just 18 mm and the 3m-long cable enables flexible installation. The DTD sensor system is based on an established LVDT measuring method. It impresses with outstanding precision and provides high signal stability and resolutions down to the micrometer range. Thanks to its high temperature stability, resistance to shock and vibration, and insensitivity to dirt, the induSENSOR DTD is ideal for industrial measurement tasks. Modern fieldbuses such as Ethernet, PROFINET or EtherCAT are supported via optionally available interface modules.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of highly stressed and relatively slowly running gears where due to leakage a grease must be used instead of oil For drives under high and shock load Chain lubrication of e.g. hollow pins, chains in the conveyor and transport field, under the influence of water and vapour and at higher operation temperatures Bearing lubrication of roller and plain bearings at annealing furnaces and drying equipments, manipulators and robots, conveyor and cooling systems, machines of preserve industry, steam sterilizers, etc. Advantages and benefits Best use in corrosive operation conditions with high operation temperatures and high pressure and shock load Economically due to optimum formulation Reduces wear and thereby downtime and enables long-term lubrication Ropy, strongly adhesive, temperature and water resistant, noise dampening, high-load and shock absorbing

Request for a quote

FATH GMBH

Germany

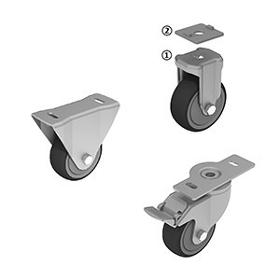

Swivel and fixed castor Fastening by means of special adapter plates (accessories) or integrated mounting plates especially for use with aluminum profile systems, as positive locking and anti-rotation fastening without lateral protrusion on aluminum profiles with pitch 38 mm -1.5", 40 mm and 45 mm Swivel castors with double locking device; the locking device prevents the wheel from rolling or turning Fixed castors have no lock wheel body diameter: 80/100/125 Tread: TPE gray RAL 7031/7024; solid rubber gray RAL 7001, black, PA, black plain bearing, Design: ESD-capable possible Material housing: steel, aluminum powder coated Material adapter plate: zinc die-cast, aluminum color powder-coated different load capacity: 600-1200 N Translated with www.DeepL.com/Translator (free version) possible accessories: extension arm

Request for a quoteResults for

Plain bearings - Import exportNumber of results

29 ProductsCompany type