- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pharmaceuticals

Results for

Pharmaceuticals - Import export

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

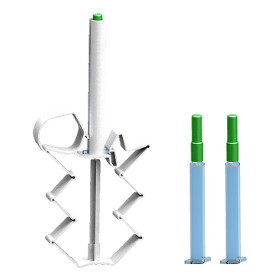

The compact 3VPHD8 Pharma Dispenser enables precise and reliable dosing of a wide variety of materials. Thanks to the special rotor-stator-geometry, no valve is required to prevent the medium from flowing out independently. Alternating opening chambers ensures gentle product transport and pulsation-free output. The VPHD series was specially developed for applications in the pharmaceutical, biotechnology, medical and food industries. Your advantages: - Interior with optimised dead space - Design according to EHEDG guidelines - FDA-compliant design/development - hygienic and pharmaceutical design - Works certificate 3.1 (DIN EN 10204) - all surfaces for pharmaceutical applications Ra ≤ 0.8 μm - retraction option (no dripping or thread pulling) - absolutely linear relationship between rotor speed and spread rate - long service life due to media-specific component selection

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

After every successful filling of a package, it is a basic condition for precise dosing that the thread is defined and breaks off cleanly. This effect usually occurs with water-like materials - with viscous products, so called semi-solids, but often not: Many products such as creams, gels and ointments pull long threads from the tip of the dispensing needle into the respective packaging. The ViscoTec Pharma Dispensers provide a solution: After a dosing shot of the Pharma Dispenser, the product path through the chambers in the rotor-stator system is blocked, thus preventing dripping of the dosing medium. A valve at the dosing needle or at the pump is not necessary. Thanks to the reversible direction of rotation, retraction can be set after the end of dosing: The material is drawn back into the dosing needle in a defined manner.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The pneumatice pinch valve with its integrated positioner is non sensitive by contaminated, granulated, viscous, doughy and aggressive media. Furthermore it is (depending on the tube material) suitable for sanitary and aseptic applications because of the FDA approval.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The pinch valve is non sensitive by contaminated, granulated, viscous, doughy and aggressive media. Furthermore it is (depending on the tube material) suitable for sanitary and aseptic applications because of the FDA approval.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Probably the most hygienic way of controlling a flow of media is for the valve not to touch the media at all. The endless tube pinch valve operates according to this principle. The medium is channelled through a tube and the valve compresses the tube pneumatically. This constriction of the hose adjusts the flow. This principle means the valve is suitable for lots of critical applications in the chemicals, food and pharmaceuticals industries.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Probably the most hygienic way of isolating a flow of media is for the valve not to touch the media at all. The endless tube pinch valve operates according to this principle. The medium is channelled through a tube and the valve compresses or releases the tube pneumatically. The built in stroke limitation prevents the tube from being overloaded.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Probably the most hygienic way of shutting off a flow of media is when the valve does not touch the fluid at all. This is the principle used by this small diameter endless tube valve, in which the fluid is passed through a hose pneumatically compressed or relieved by the valve.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The 3A compliant hygiene right angle valve type 6052 with integrated positioner was specially developed for applications in the dairy industry, but also in food and beverage production. The 6052, available in nominal sizes DN15 to DN50, meets the highest requirements for purity and control quality. All wetted parts comply with FDA and regulations (EG) 1935/2004 and (EU) 10/2011.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The aseptic right angle valve type 6051 with EHEDG Certification and integrated positioner type 8049 is perfectly suitable for applications in pharmaceutical and food processing industry as well as in the biotechnology and cosmetics. All wetted parts comply with FDA, USP class VI and regulations (EG) 1935/2004 and (EU) 10/2011.

Request for a quote

EDDYLAB GMBH

Germany

The SLX series is derived from the SL series and has been especially for use in applications in the pharmaceutical, medical and food industries. To reduce machine downtimes, CIP and SIP ("cleaning in place", "sterilization in place") cleaning and sterilization processes are state of the art today. For this purpose, the machine interior is cleaned thermally and/or chemically with high temperature, pressure and aggressive media. The devices of the SLX series are perfectly equipped for use in this area and guarantee maximum reliability and service life thanks to their extremely robust design, a completely sealed stainless steel housing and high media and temperature resistance. KeyFeatures ■ Measuring ranges 10...300 mm ■ Linearity up to ±0.10 % of measuring range ■ High protection class IP68/IP69K ■ Operating temperature sensor up to 200 °C ■ High resistance to aggressive media ■ Customized designs

Request for a quote

GEBR. DÜRRBECK KUNSTSTOFFE GMBH

Germany

High-quality blown film forms the basis for Dürrbeck’s tailor-made packaging solutions. Depending on the size, weight and volume of the goods to be packaged, the bottom seal bag and the flat bag are among the most popular types of packaging. Universal plastic bags for various purposes, they are ideal for storing and protecting pharmaceuticals, food, small electrical parts or building materials and textiles against dust, dirt or the elements. Our bottom seal bags are made for smaller-sized contents, flat bags for bulky and heavy items (from 400 x 600 mm). Bottom seal bags and flat plastic bags are easily manufactured plastic bags made of polyethylene (LDPE, HDPE, MDPE) – without side gussets, closures or the like. This type of packaging offers excellent protection and is an attractive, effective way to present your products.

Request for a quote

PHENOMENEX LTD.

Germany

Access our library of over 100 training webinars. These presentations cover topics for multiple industries supported by Phenomenex, with tips for improving applications, optimising methods and troubleshooting analytical system problems. All webinars are free to access.

Request for a quote

PHENOMENEX LTD.

Germany

Verex HPLC, GC, and autosampler vials offer the lowest ion content possible to reduce sample loss and contamination. From start to finish, Verex HPLC, GC, and autosampler vial and cap products are manufactured to provide high quality, state-of-the-art solutions for your most challenging, sensitive applications. No vial is placed in inventory without passing cleanliness and performance testing for consistency resulting in a certified, 100% defect-free vial you can trust.

Request for a quote

GAPLAST GMBH

Germany

SOLID Oral Container Closure Systems The preliminary task of each packaging system is to store and protect the content. But at the same time it is also inevitable to match the ease of use when opening and closing the container. Whilst fitting to different designs of container openings, like • snap on (Ø 19,85 mm – 54,50 mm) • screw or different container materials, like • plastic • aluminium • glass the following closure features are available solely or in combination: • tamper-evident • with integrated desiccant • for tablet storage • with distance holder: by an additional bellow or by an integrated spiral • childproof (ISO 8317 & CFR §1700.20) by integrated, self-resetting push-pull slider Senior friendly desiccant stopper with pull tab Unfortunately, a gain in ages usually goes along with a loss in power. Therefore, the target is to engineer an easy to use packaging which also fulfils pharmaceutical requirements. System Benefits (B2B) • Compatible to standard and already in.

Request for a quote

GAPLAST GMBH

Germany

LIQUID Sub-cutaneous Use The prefilled syringe is mounted into the reusable activation device. After removal of the tip cap, the ModularInject is placed to the injection point. By activating the device, the skin is penetrated and the drug substance is injected. After the injection is finished, the syringe is discharged and can be disposed as usual. The activation device is ready for the following administration. ModularInject Monodose Injection Unique and smart solution to close the gap between manually applied prefilled syringes and complex auto-injectors. Single Use: Prefilled syringe with tip cap Multiple Use: One-piece activation device with an integrated plunger, automatic penetration, traveller and needle security functionality System Benefits (B2B) Applied/used either with a standard prefilled syringe in accordance to ISO 11040-4 or alternatively with an own developed packaging optimized prefilled syringe Free set combination of different dosages or different drugs...

Request for a quote

GAPLAST GMBH

Germany

LIQUID, SEMISOLID Nasal, Ophthalmic, Topical, Oral, Auricular Use The prefilled cartridge is mounted via bayonette into the reusable activation device. After twisting off the tamper evident tip, the modular dose is placed to the intended area of application and the activation device is squeezed to apply the product. Monodose with spray or drip pattern or injection (ModularFamily) Monodose with spray, drip or line pattern ModularUnitDose The evolution of a monodose results in the patented new development of the ModularUnitDose with a spray, drip or line pattern. To achieve this functionality, the modular dose consists of the following components: Single Use: Prefilled cartridge with a tamper evident twist off tip Tip design according to spray, drip or line pattern Moveable stopper Multiple Use: One-piece activation device with an integrated piston System Benefits (B2B) Reliable and correct dosage of drug delivery Combination of different dosages possible, just by varying the...

Request for a quote

GAPLAST GMBH

Germany

LIQUID, SEMISOLID Nasal, Ophthalmic, Topical, Oral Use The AirlessMotion products can be combined with numerous dispensing units for: horizontical or vertical outlets spray, dropper or lotion pumps snap, crimp or screw neck design push button or trigger activation Airless container for pump & squeeze application AirlessMotion Reaching the utmost level of integrity sterility without preservative agents also during multiple use of a dosing system, requires highly engineered packaging. First of all, the container itself has to match these needs. A multilayer bottle has been evolved into a hybrid packaging consisting of a rigid bottle layer and a flexible, contracting integrated bag. The resulting system allows an airless pump not to vent the container with contaminated air during multiple applications, also if there are longer pauses in-between. Numerous patents are protecting the IP of product, function and process. Benefits of the system (B2B) Formula without preservative...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Pharmaceuticals - Import exportNumber of results

18 ProductsCompany type

Category

- Pharmaceuticals - basic and auxiliary products (7)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Pharmaceutical industry - machinery and equipment (1)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Measurement - Equipment & Instruments (1)

- Bags, plastic (1)

- Inductive sensors (1)