- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- petrochemical plants

Results for

Petrochemical plants - Import export

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High Temperature Gasket of Expanded Flexible Graphite with Stretchmetal Characteristics Expanded graphite sheet gasket with Stainless Steel stretch metal reinforcement and a purity of 99 %. Practically no cold flow or creep under temperature. Non hardening Excellent in use with cycling temperatures. Blow out safe due to 3 dimensional reinforcement matrixes Optimized transfer of sealing stress Safe use even with small sealing width Minimized risk of separation known from multilayer reinforced gasket sheets. Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C, n oxidizing atmosphere +450 °C Pressure: p = 200 bar Main application Universal use as problem solver in all industries when demanding higher operation safety and sealability especially in older plant equipment. Suitable for Chemical industry Petrochemical plants Pharmaceutical industry Power plant technology Paper industry Sugar industry Approvals DVGW BAM TA Luft FIRE SAFE API 607 on request Form of...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High strength ePTFE-Graphite Characteristics Extrusion resistant even with large clearances Form stable, wear resistant, heat conductive and can be used as bull ring Shaft protecting (recommended surface hardness: HRC 25) In high pressure applications die formed rings are recommended Operating range Pressure [p max]: 30 bar, Velocity [v max]: 8 m/s Pressure [p max]: 800 bar, Velocity [v max]: 3 m/s Pressure [p max]: 500 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.35 g/cm³ Main application High pressure plunger- and dosing pumps Bullrings for mixers, highpressure valves agitators, gate valves and valves Suitable for Chemical industry Petrochemical plants High pressure machine constructions Approvals BAM for liquid and gaseous oxygen 60 °C/15 bar, 40 °C/65 bar, 200 °C/50 bar Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre-compressed ring-set made of expanded graphite and reinforcement to protect against extrusion Characteristics Packingset made by combining two expanded Graphite grades and designs in order to avoid blow out and extrusion and as well enhance the sealability of this valve sealing set. The set was tested and approved by the AMTEC GmbH Lauffen in Germany. The leakage parameters of 8.6 x 10-3 mbar · l/(s·m) complies with the VDI 2440 at +400 °C, which specifies a maximum allowed leakage of 1.0 x 10 -2 mbar · l/(s·m) (test media helium) and is therefore recommended as a high grade seal system. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 160 [bar] Temperature without LiveLoading: t 400 °C Temperature with LiveLoading: t 400 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Suitable for Power plant technology Chemical industry Petrochemical plants Boiler houses Refineries Approvals TA Luft / VDI 2440 Certificate

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre compressed Packing set of expanded graphite with Inconel Matrix reinforcement and special PTFE coating Characteristics Ring Set made from special high temperature resistant yarn and pore filling cross section impregnation fulfills with a tested leakage rate of 8.4 x 10 -3 mbar · l/(s·m) the leakage criteria of VDI 2440 +400 °C with a maximum allowable leckagerate of 1 x 10 -2 mbar l/(sm) and is suitable for temperatures up to +300 °C. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 100 [bar] Temperature without LiveLoading: t +300 °C Temperature with LiveLoading: t +300 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Control Valves Suitable for Power plant technology Chemical industry Petrochemical plants Boiler houses Approvals TA Luft / VDI 2440 Certificate ISO 15848-1 CC1 ISO 15848 test was conducted with 20,000 mechanical cycles and 2 thermal cycles (RT, +200 °C) and passed with a leckagerate of 6.1 x 10 -4 mg/s/m.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre-compressed Packing Set of specially impregnated PTFE fiber packing Characteristics Ring set made of pure PTFE packing and PTFE compound bull rings fulfills with a tested leakage rate of 4.2 x 10 -5 mbar · l/(s·m) the leakage criteria according to VDI 2440 +200 °C with a maximum allowable leakagerate of 1 x 10 -4 mbar l/(sm) and is suitable for temperatures up to +200 °C. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 100 [bar] Temperature without LiveLoading: t +200 °C Temperature with LiveLoading: t +200 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Suitable for Power plant technology Chemical industry Petrochemical plants Approvals TA Luft / VDI 2440 Certificate

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Braided of Flexible Expanded Graphite Tape with High Temperature Metal Mesh Reinforcement Practical useful application data: max. temperature in oxidizing atmosphere: +400 °C Characteristics Universal plant wide use in static applications Extrusion stability through ultrafine 10 myh metal mesh reinforcement on each strand Non hardening, good reset capability, coefficient of thermal expansion corresponds to the coefficient of steel High temperature and pressure resistance Suitable for: power plants, petrochemical plants, boiler houses Easy to cut, assemble and disassemble Low coefficient of friction minimizes the adjustment force in valves For valve applications rings should be approx. 25 - 30 % compressed at installation A 66 can be used as bullrings for style A 44, A 44 I and P 60 Die formed rings are recommended Operating range Pressure [p max]: 500 bar Temperature: t = -200… +650 °C pH: 0 - 14 Density: 1.15 g/cm³ Practical useful application data: max. temperature in...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Braid of Flexible Expanded Natural Graphite Tape Reinforced with Inconel Wire Practical useful application data: max. temperature in oxidizing atmosphere: +400 °C Characteristics Universal use valve packing Expanded graphite of higher quality Coefficient of expansion similar to steel For valve applications rings should be approx. 20 - 25 % compressed at installation Precompressed rings are recommended Operating range Pressure [p max]: 300 bar Temperature: t = -200… +550 °C pH: 0 - 14 Density: 1.20 g/cm³ Practical useful application data: max. temperature in oxidizing atmosphere: +400 °C Main application Valves Fittings Gate valves Flaps Plunger Door and lid seals Suitable for Power plant technology Petrochemical plants Boiler houses High pressure- and high temperature applications For higher pressure and temperature applications use suitable bullrings. Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Braid of Flexible Expanded Natural Graphite Tape Practical useful application data: max. temperature in oxidizing atmosphere: +400 °C Characteristics Universal use in pumps and valves Very good dry-running characteristics No wear, perfect thermal conductivity High quality pure graphite Coefficient of thermal expansion similar to steel Rings should be approx. 20 - 25 % compressed during assembly Recommended as die formed rings Operating range Pressure [p max]: 20 bar, Velocity [v max]: 20 m/s Pressure [p max]: 300 bar Temperature: t = -200… +550 °C pH: 0 - 14 Density: 1.15 g/cm³ Practical useful application data: max. temperature in oxidizing atmosphere: +400 °C Main application Valves Fittings Gate valves Flaps Door and lid seals Suitable for Power plant technology Boiler houses Petrochemical plants High pressure- and high temperature applications For higher pressure and temperature applications use suitable bullrings. Form of delivery This packing can be manufactured from 3...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

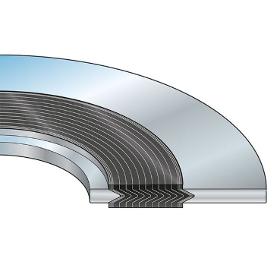

Spiral wound gasket made of crimped metal tape with sealing wraps of non asbestos gasket material. Optional: inner and/or outer metal ring. Characteristics For flange connections in high pressure pipe line construction and fittings Extremely low leakage with PTFE spiral. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance to 550 °C with graphite spiral Media resistance: pH 0 - 14 Max. pressure load: p = 400 bar Temperature range: t = -200 to +550 °C Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C Pressure: p = 400 bar Main application High temperature and high pressure flanges Piping Pressure vessels Heat exchangers Fittings Suitable for Power plants Petrochemical plants Chemical industry Material Centerring ring OD: Carbon Steel galvanized Spiral: 316L Centerring ring ID: Carbon Steel galvanized Other material combinations on request Product Types SF 11 Spiral wound gasket without any center ring for flanges with tongue and groove connection SF...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

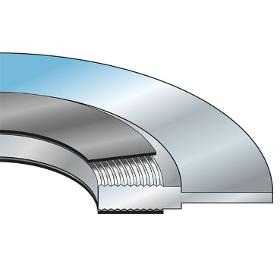

D 7 ProCor Camprofile Gasket, Rip profiled metal base covered with graphite or PTFE, optional with or without center ring(s). 1] pay attention to the temperature limit of PTFE Characteristics For flange connections in high pressure piping and in fittings Extremely low leakage values with PTFE inlay. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance up to 550 °C with graphite inlay Technical parameters Covermaterial PTFE Temperature range: -200... +260 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 Covermaterial Graphit Temperature range: -200... +500 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 1] pay attention to the temperature limit of PTFE Main application For all flanges inside the main traction line High level of temperature and pressure resistance Suitable for Power plants Petrochemical...

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

Vibration analysis in explosive environments VIBXPERT EX is a highperformance, intrinsically safe, fullyfeatured data collector, vibration analyzer and field balancer for easy condition monitoring and troubleshooting of rotating equipment in explosive environments such as petrochemical plants, refineries, offshore oil rigs, etc. VIBXPERT EX collects field data including vibration information, bearing condition, inspection and process data and seamlessly integrates with the OMNITREND Center software platform for indepth analysis. The modular firmware structure allows you to upgrade the VIBXPERT EX from a route data collector to a fullblown troubleshooting device with advanced features such as coast down/runup measurements, event recording, ODS & modal analysis and crosschannel phase measurement.

Request for a quoteResults for

Petrochemical plants - Import exportNumber of results

12 ProductsCompany type

Category