- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- operating equipment

Results for

Operating equipment - Import export

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hygienic angle seat valve type 7015 is ideal for applications in food and beverage production. The valve can be used to shut-off product streams, drinking water, CO2, nitrogen as well as sterile steam and sterile air. All wetted plastics are FDA-compliant and conform to EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. The hygienic angle seat valve is also certified to Technical Instructions on Air Quality Control (TA-Luft) in accordance to ISO 15848-1 and on request can be supplied with an acceptance test certificate in accordance with EN10204 3.1.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hygienic angle seat control valve type 7025 with integrated digital positioner is specially adapted for use in the food and beverages production. Suitable for controlling product streams, drinking water, CO2, nitrogen as well as sterile steam and sterile air. All wetted plastics are FDA-compliant and conform to EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. The hygienic angle seat valve is also certified to Technical Instructions on Air Quality Control (TA-Luft) in accordance to ISO 15848-1 and on request can be supplied with an acceptance test certificate in accordance with EN10204 3.1.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The pneumatic flanged sliding gate control valve type 8621 in GS3 design with integrated positioner designed according to ASME B16.34, API RP 553, API 598, ASME B31.1 and ASME B31.3 incl. flange connection according to ASME B16.5 is suitable for a wide range of process applications. Media such as steam, liquids, gases, etc. can be handled perfectly.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated angle seat valve is the extremely reliable allrounder in valve technology and is predestined for very high switching capacities. In stainless steel design for neutral and aggressive media but also for a wide range of temperature applications suitable. The angled seat design offers a high flow rate.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The three-way ball sector valve type 4080 with integrated positioner in diverting or mixing function is ideal for a wide range of process control applications. Due to its design, the three-way ball sector valve enables high-precision control over a wide range and features exceptionally high Kvs values in all flow directions.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated globe valve type 7027 with integrated positioner for control applications with neutral to highly aggressive media. The straight design enables a highly efficient and very simple insulation of the valve body as well as the welded-on pipeline.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated globe valve type 7017 in stainless steel design for on-off applications with neutral to highly aggressive media. The straight design enables a high flow rate as well as a highly efficient and very simple insulation of the valve.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

Temperature is one of the most measured physical parameters. Despite this, precise temperature measurement is one of the most difficult tasks in motor technology. To meet the constantly increasing requirements for improved motor performance, higher efficiency and reduced emissions, it is necessary to use reliable and precise sensors in modern motor control systems. The increased requirements over the last few years regarding measurement accuracy and reliability of temperature measurements has meant that many equipment operators must reconsider the suitability and performance capacity of their temperature measurement equipment. Resistant thermometers can be used between -200 °C and +850 °C. An important common property is that their output parameters are available in the form of electric signals that can be relatively easily transferred to measurement and control instruments for processing, storage and display.

Request for a quote

GEDA GMBH

Germany

Wherever heavy loads have to be transported to great heights, the new GEDA BL 2000 P ensures the required efficiency in the industry. With a load capacity of 2000 kg or 23 persons and a max. lifting speed of 40 m/min, this permanent passenger and material hoist is the new powerhouse from GEDA. The fixed platform size of 3.20 x 1.45 x 2.10 m also allows transport of bulky goods up to a height of 250 m. For added comfort and operating convenience, the hoist is equipped with comprehensive state-of-the-art control variants. The GEDA BL 2000 P is perfectly tailored to the requirements in rough industrial environments. Maintenance and repair work can be conducted efficiently with the permanent passenger and material hoist.

Request for a quote

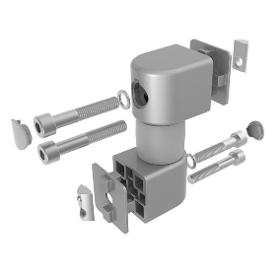

FATH GMBH

Germany

Description: Connection joint with friction for the creation of system arms using profile pieces; pivotable 360°; friction joint can be attached lateral, transverse, or on the face of the profile; if attached on the front face, the core hole of the respective profile must be M8 threaded (min. 15 mm deep) Material: Housing: Aluminum die-cast Cover ring: Plastic Inserts: Steel Friction shaft: Steel Cover caps: Plastic Screws: Steel Washers: Steel Centering plates: Aluminum die-cast T-slot nuts: Steel Surface: Housing: Laquered Centering plates: Laquered Screws: Zinc plated Washers: Zinc plated T-slot nuts: Zinc plated Color: Housing: Alu color Cover ring: Gray ≈ RAL 7042 Cover caps: Gray ≈ RAL 7042 Centering plates: Alu color Set: Various Sets available - Please contact us for Details Pack Quantity: 1 piece/set

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The COMPENSER® of the DC-series is an ideal hydraulic shock reducing element especially for the application field of storage technology (storage and retrieval machines). As a doubleacting buffer, this industrial shock absorber can be used in a spacesaving manner due to its design and can be actuated alternately from both sides. The constructive design and function corresponds to the C-Type. Furthermore, due to its low reset force, it can easily be pressed in at creep speed during operation. As optional equipment PU caps as inserts for the impact cap for the reduction of impact noise and a monitoring of the piston rod‘s position (by either magnetic or inductive sensors) are available. If only a slight increase of reset force of the piston rod over the entire stroke is desired, an additional external accumulator can be fitted to the cylinder to increase the gas volume of the gas spring. Hence the reset force decreases in retracted state.

Request for a quote

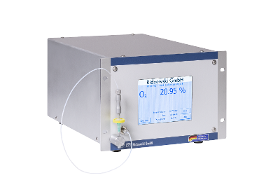

RIDZEWSKI GMBH

Germany

The EPC VM is our measuring device for monitoring O2/CO2 in packaging machines. In addition to continuous measurement of the gas atmosphere, spot measurement of individual packages is also possible. The functionality is the same as with our Zr-Ox EPC spot analyser. Once set, the analyser can also control the gassing of the machine. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels

Request for a quote

RIDZEWSKI GMBH

Germany

The Zr-Ox EPC is our standard model for continuous monitoring of residual oxygen. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels - Standardised 0/2-5/10 VDC or 00/04-20 mA analogue signal adjustable - 3 backups for storing different unit functions and settings - Display of all alarms and errors

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

1500 - 19000 CFM / 2,500 to 33,000 m³/hr Nash's 2BE3 & 2BE4 vacuum pump series offers capacities ranging from 1,500 to 19,000 CFM (2,500 to 33,000 m³/hr). Designed to operate in demanding environments like the paper, power, mining and chemical process industries, these pumps offer durability and reliability at a low cost of operation. Each model is equipped with an application-proven polyisoprene-lined body for added corrosion & erosion resistance. The unique inlet configuration allows for both top and side inlet arrangements to accommodate low headroom installations. In installations where space is limited, the top discharge capability of the 2BE4 allows the use of a top mounted discharge separator that saves floor space and eliminates the need for a trench. The pumps allow efficient operation over the entire vacuum range without the need to change the pump's internals. When equipped with a center shroud, split vacuum operation up to 12 in. Hg (400 millibar) differential can be achieved. Large inspection ports allow easy access to pump internals for inspection and maintenance. For more aggressive applications, stainless steel, stainless steel clad and epoxy coated components are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

1500 - 19000 CFM / 3,000 to 9,500 m³/h Nash's 2BE3 and 2BE4 series compressors have capacities ranging from 1,500 to 19,000 CFM (2,500 to 33,000 m³hr). Designed to operate in demanding environments like the paper, power, mining and chemical process industries, these compressors offer durability and reliability at a low cost of operation. Each model is equipped with an application-proven polyisoprene-lined body for added corrosion & erosion resistance. The unique inlet configuration allows for both top and side inlet arrangements to accommodate low headroom installations. In installations where space is limited, the top discharge capability of the 2BE3 and 2BE4 allows the use of a top mounted discharge separator that saves floor space and eliminates the need for a trench. These compressors allow efficient operation over the entire vacuum range without the need to change the compressors's internals. When equipped with a center shroud, split vacuum operation up to 12 in. Hg (400 millibar) differential can be achieved. Large inspection ports allow easy access to pump internals for inspection and maintenance. For more aggressive applications, stainless steel, stainless steel clad and epoxy coated components are available.

Request for a quoteResults for

Operating equipment - Import exportNumber of results

16 ProductsCompany type