- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical engineering

Results for

Mechanical engineering - Import export

VOXELJET AG

Germany

The VX500 is a 3D printer for industrial applications that has been tried and tested many times over in practice. These machines can be found wherever there is a demand for the straightforward production of prototypes and models. Despite their compact dimensions, they captivate with the features of a high-performance printer, such as multi-jet print heads, integrated material handling and job boxes. The machine is very fast, easy to operate and permits cost-effective production of both individual parts and small series alike. Plastic can be used as the particulate material. The machine's build space measures 500 x 400 x 300 mm. The VX500's print head system can achieve a resolution of up to 600 dpi. The thickness of a layer applied in one cycle is 150 µm. In addition, the VX500 concept is resource-friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quote

VOXELJET AG

Germany

The VX4000 is the world's biggest industrial 3D printing system for sand molds. It has a cohesive build space measuring 4,000 x 2,000 x 1,000 mm (LxWxH). This machine can be used to economically produce very large individual molds, a great many small series components or a combination of the two. With its uniquely large volume, the VX4000 maximizes productivity and flexibility. The unique and patented layering process was specially adapted for this printer. Instead of lowering the building platform during the printing process, the print head and coater are raised with each layer. As a result, the machine can bear the enormous weight of the building platform, which can be quickly exchanged via a rail—making it possible to print nearly continuously. Sand can be used as the particulate material. The VX4000's print head system can achieve a resolution of up to 300 dpi. A layer applied in one cycle is 300 µm thick.

Request for a quote

VOXELJET AG

Germany

The VX2000 is a 3D printer for industrial applications. It is a particularly good choice for cost-effectively producing large-format models from sand cores for prototyping. The VX2000 can also be used to economically manufacture small-series components. The machine is fast and easy to operate. The build space measures up to 2,000 x 1,000 x 1,000 mm. The VX2000's print head system can achieve a resolution of up to 300 dpi. A layer applied in one cycle is 300 µm thick.

Request for a quote

VOXELJET AG

Germany

Our international bestseller: the VX1000 is a universal 3D printer for industrial applications. The machine is fast, easy to operate and enables you to cost-effectively produce medium-sized molds, cores and models for making prototypes. The VX1000 is also suitable for producing small series. Plastic and sand can be used as the particulate material. The piezo print head system of the VX1000 achieves a resolution of up to 600 dpi. The machine's build space measures 1,000 x 600 x 500 mm. The thickness of a layer applied in one cycle is 150 µm for plastic and 300 µm for sand. In addition, the VX1000 concept is environmentally friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quote

VOXELJET AG

Germany

The VX200 is the most compact 3D printer in the voxeljet portfolio. It weighs a mere 450 kilograms and, thanks to its dimensions of only 1,700 x 900 x 1,500 mm (LxWxH), the VX200 can be installed without problems in places where space is tight, such as research laboratories. The machine is very fast, easy to operate and permits the economical production of small prototypes and design pieces. Plastic and sand can be used as the particulate materials. The build space measures 300 x 200 x 150 mm. The VX200's print head system can achieve a resolution of up to 300 dpi. The thickness of a layer applied in one cycle is 150 µm for plastic and 300 µm for sand.

Request for a quote

FLOTTWEG SE

Germany

The Flottweg Tricanter® For Three-Phase Separation In three-phase separation, it is possible to separated two liquid phases from one solid phase at the same time. The Flottweg Tricanter® is the perfect partner for separating these three phases. Tricanter® - Typical Applications For Three-Phase Separation - Processing of sludges containing oil from refineries, oil ponds, etc. - Extracting animal/vegetable fats and oils - Starch manufacture for separating wheat starch and gluten Tricanter® - Advantages And Customer Benefits - Greatest possible purity of the liquids to be separated, by using the impeller - Other processing steps/separating stages can be dispensed with, or are no longer required, thereby offering cost savings for the plant owner - Adaptation to changing conditions (product in the feed) possible at any time - Automation is possible - Produced, manufactured and developed in Germany, for the highest possible production quality

Request for a quote

FLOTTWEG SE

Germany

Recycling plastics with the Sorticanter include: ► Reduced odor because of closed system ► No influence due to the color of the solids to be sorted ► Lower thermal energy consumption, since the dewatering phase is already built into each Sorticanter. ► Minimum personnel costs, creating operating cost savings ► Separation of mixed substances that are unsuitable for static separation (fibers) This means that no mechanical dryer (screen centrifuge) is needed. ► Processing of particles possible that are smaller than 1 mm, so no impact from fans and other interfering effects ► A low-volume circulation system reduces the consumption of fresh water, while also reducing the wastewater quantity, since contaminants are largely separated out in the Sorticanter. With a Sorticanter, it is possible to process up to 1,000 lbs or 2,500 kg of solid per hour, depending on the composition of the raw materials.

Request for a quote

FLOTTWEG SE

Germany

In many aspects of process engineering, separators are used for mechanical separation and clarification of mixtures comprising solids and liquids. A separator is liquid-oriented and works with a higher rotation speed than a decanter. As a result, the generated centrifugal acceleration (g number) of a separator is significantly more powerful than in decanter centrifuges. Flottweg separators are suitable for separating ultrafine solid particles from a liquid (clarifier separator). Furthermore, Flottweg separators are suitable for separating mixtures of liquids with different densities at the same time as separating a solid (purifier). Flottweg AC separators (Automatic Cleaning) can be used in a wide range of applications, and are also available in various configurations. — Beverage and brewing industry — Starch industry — Chemicals and biotechnology — Extracting and processing fats and oils

Request for a quote

FLOTTWEG SE

Germany

Disc stack centrifuges are high-speed centrifuges for the mechanical separation and clarification of mixtures comprising solids and liquids. Due to their special design, disc stack centrifuges work at a very high rotation speed. As a result, the centrifugal acceleration (g-force) generated by a disc stack centrifuge is extremely powerful. Moreover, the discs included provide a large clarifying area. Thus, it is possible to separate ultrafine solid particles from a liquid and to separate liquid mixtures in an efficient way.

Request for a quote

FLOTTWEG SE

Germany

A decanter can be thought of as a settling basin that wraps around an axis. In the settling basin, the solid particles that are heavier than the liquid move to the bottom by gravity and form a sediment at the bottom of the basin. In the rotating drum of the centrifuge, the solid particles that are heavier than the liquid move outward by centrifugal force and form a sediment on the inner wall of the centrifuge drum. Since forces of about 3000 g occur in a centrifuge, as opposed to 1 g in the gravitational field, the separation of the solid particles from the liquid is much faster and more efficient.

Request for a quote

FLOTTWEG SE

Germany

Like all machine sizes in our C series, the C5E is also equipped with optimum wear protection. This reduces maintenance costs, as only wear parts need to be replaced. At the same time, this ensures a longer service life and high machine availability. The Flottweg features Recuvane® and Simp Drive® make the simple, efficient and individual operation of the centrifuge perfect.

Request for a quote

FLOTTWEG SE

Germany

The Flottweg Z-Series offers decisive advantages for our customers that make us special. Providing the extra efficiency: — Continuous operation — Optimum separation result and energy recovery due to customized bowl and screw geometry — complete wear protection thanks to high-quality stainless steel and robust design — compact and space-saving machine design — Quality Made in Germany

Request for a quote

FLOTTWEG SE

Germany

From algae harvesting to beer clarification and protein extraction: If you want to separate or purify liquids or remove ultra-fine particles you need strong and robust separators. Where decanter centrifuges reach their performance limits, the use of separators begins. Thanks to their high speeds, they are able to optimally process liquids. Clarifiers (2-phase separation), separate the finest solid particles from a liquid. As purification separators (3-phase separators), they separate liquid phases of different densities and simultaneously remove solids. Equipped with special features as the Flottweg Soft Shot® discharge system our products belong to the high qualitative products on the market.

Request for a quote

FLOTTWEG SE

Germany

Flottweg nozzle separators (2- and 3-phase nozzle separators) are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. The product to be clarified or separated flows via a stationary inlet pipe into the inside of the bowl and is gently accelerated to operating speed by the distributor.

Request for a quote

FLOTTWEG SE

Germany

This new decanter series combines the latest know-how in manufacturing, design and engineering with decades of experience. Thus, with the C4E environmental centrifuge, we offer an optimal solution for medium-sized wastewater treatment plants for which quality, reliability and a good price-performance ratio are important.

Request for a quote

FLOTTWEG SE

Germany

Are you looking for an optimal and highly efficient solution for your process? Then our Z-series is the right one for you. These Flottweg High-Performers can be used in the food industry, mining or even the recycling of by-products - and these are just a few examples. With very low maintenance and the best quality of our components, you can be sure that the Flottweg decanter will meet your requirements. If you are one of Flottweg's customers for whom cleanliness and hygiene are particularly important, we will be pleased to build your machine according to the hygienic design.

Request for a quote

FLOTTWEG SE

Germany

Flottweg Technology serves over 1000 applications worldwide. Each of these engineering processes are as individual as our Z series decanter centrifuges. From the food to the pharmaceutical industry to the processing of by-products - so specific, individual and optimized, our Z series can meet many challenges with flying colors. Hygienic design, for our customers where cleanliness matters, can be guaranteed in every machine. Special ATEX protection ensures safety and our own Simp Drive® drive system make the technological performance perfect.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLOTTWEG SE

Germany

The Flottweg Z8E: The Giant Decanter With the new Z8E decanter centrifuge, Flottweg is extending its product range and setting new standards. Right from the start of development of the Z8E, the target was set of concentrating on the specific requirements of an extremely wide range of industries. The modular design of this decanter centrifuge means it is possible to adjust optimally to all kinds of separating tasks. Irrespective of whether two-phase or three-phase separation is involved, Flottweg always has the right machine configuration available with the Z8E decanter centrifuge. Typical Applications of The Flottweg Z8E - Mining and the processing industry - Chemicals and biotechnology - Foodstuffs and beverage industry - Vegetable oils, animal fat and renewable fuels - Wastewater and oil sludges

Request for a quote

FLOTTWEG SE

Germany

The New C2E Decanter Centrifuges for Small Treatment Plants Flottweg presents a new era of sludge dewatering for small sewage treatment plants. The C2E decanter centrifuge was developed specifically for the dewatering and thickening of smaller sludge loading rates. It features all of Flottweg's know-how in a compact, space-saving design. Over five decades, Flottweg has gathered rich knowledge of the area of sewage sludge thickening and dewatering. That know-how has been transferred into a new generation of environmental centrifuges. Our requirements for the C2E are just as high as for the big Flottweg Decanters. Disposal costs still play a central role, even for small communities. The quality of the machine and its efficiency regarding separation results reduces the overall lifetime costs to a minimum. Want to learn more about our solutions? Then get in touch.

Request for a quote

FLOTTWEG SE

Germany

Transport and disposal costs, at over 70 percent, represent by far the largest cost item in sludge dewatering. A powerful dewatering assembly is thus an important criterion. With a Flottweg HTS Decanter in the C series, you can achieve the highest possible total dry solids in the dewatered sludge, thereby continuously saving on transport and disposal. More than 50 years of experience in the dewatering of sewage sludge and continuous further development have gone into the design of the Flottweg HTS Decanter. This experience, combined with references from the entire world, makes Flottweg one of the leading providers of mechanical separation technology. The HTS Decanter is attractive for its performance, its efficiency, and its high cost-effectiveness. The decanters in the Flottweg C series cover a throughput range from about 5 to over 150 cubic meters per hour. We can offer you comprehensive know-how and customized systems.

Request for a quote

FLOTTWEG SE

Germany

Success is hidden in the bowl - the separator spindle. Powerful drive motors ensure high availability of the centrifuge. This efficiency combined with quiet running sets standards in separation technology worldwide. The soft-shot system, specially designed by Flottweg, performs acoustically hardly perceptible solids discharge. Depending on the customer's requirements, it can be set as desired whether partial or full discharges are to be carried out in order to achieve higher product yields. In addition, it is possible to set the discharge times to a tenth of a second.

Request for a quote

FLOTTWEG SE

Germany

The secret of success of Flottweg separators is the separator bowl. The compact and robust design of the AC1500 convinces customers worldwide. Since the complete bowl can be assembled and disassembled as one compact component, simple and time-saving maintenance is guaranteed. The spindle of the AC1500 reaches its operating speed within a few seconds and can be flexibly adapted to product requirements through simple and variable speed control. In addition, the AC1500 operates so efficiently that power consumption can be reduced while at the same time decreasing the mechanical load on the system.

Request for a quote

FLOTTWEG SE

Germany

Reliability isn't just a keyword for Flottweg – it expresses the company's philosophy. We want our customers to get results with Flottweg that can't be beat. That requires reliable machines, reliable service, and staff whose passion for perfection shows throughout the manufacturing process. The newly developed Flottweg Z3E brings us a huge step towards that goal. This decanter centrifuge is flexible, maintenance-friendly, and powerful. With its easy-to-open cover, Flottweg makes access to the main components quick and easy, with no need for lifting equipment. Together with another feature – the super deep pond – the Flottweg Z3E highlights the know-how that has gone into this decanter. Top flexibility and quality characterize the Flottweg Z3E, which has been Engineered For Your Success.

Request for a quote

FLOTTWEG SE

Germany

The Flottweg AC1700 separator – the newest member of the Flottweg family Separators are used to separate the finest solid particles from liquids. Separators are available from Flottweg for a wide range of applications, from the production of beverages to the production of vegetable oil. Our separators are subject to different requirements depending on the application and size of the respective plant. To be able to offer our customers more options and the optimum solution, we have expanded our separator portfolio with a new machine size: the Flottweg AC1700 separator. The Flottweg AC1700 separator fits between our popular AC1500 and AC2000 series and completes our product portfolio for the food and beverage industry. With over 70,000 m² / 753,474 ft² of clarification area and an acceleration of 11,000 g, the compact separator ensures an optimally clarified final product with a high throughput.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers the complete range of conveying systems, storage systems and handling systems in mechanical engineering. Our plants and systems can be integrated into your own conveyor line or designed as completely automated systems. External plant components can also be integrated into our superordinate control system. Our plants and systems are mainly used for bagging or bottling or batch loading systems. Application of conveying, storage and handling systems: Dosing and application of liquids in the plant process Dosing and mixing of powders, fibres and liquids Bagging and bottling systems integrated into a production line Silo systems and tank systems with conveying paths and mixing systems Pipe shell plants

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The COMPENSER® of the KL-series is an industrial shock absorber for light mechanical engineering, e.g. handling equipment, small storage and retrieval machines and small crane systems. Due to the low reset force of the compression spring, this buffer of the KL-series is well suited for operational push-in cycles at creep speed. Design & Function: The piston rod 2 pushes the piston 6 into the pressure chamber 7. At the same time, the damping medium flows through the metering grooves placed in the outer tube 8, via the piston 6 and into the volume balance chamber 5. The return spring 3 is tensioned and, after the impact has occurred, pushes the piston rod 2 back to the initial position. By this the damping medium flows back into the pressure chamber 7.

Request for a quote

MIROMATIC MASCHINENBAU GMBH

Germany

miromatic – Get in touch with us if you are interested in a used system. We will be delighted to tell you about our current stock.

Request for a quote

MIROMATIC MASCHINENBAU GMBH

Germany

miromatic – The modular process technology offers individual solutions for optimising system and process performance with the objective of increasing the efficiency of the production line, preserving productivity and reducing the environmental burden. The process technology division also plans, designs and manufactures the following process engineering solutions in the foodstuffs industry: Customer-specific valve clusters Sterile air modules Pressure vessel construction per the pressure equipment directive Cooling and heating systems Continuous mixing devices (KME) Scraping heat exchangers (SWT) Thermal product treatment Servicing / system overhauls

Request for a quote

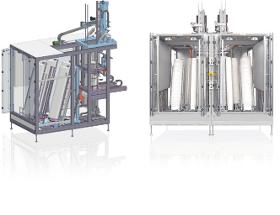

MIROMATIC MASCHINENBAU GMBH

Germany

Miromatic – Multiple stacks of tubs and lids can be stockpiled and automatically fed to the separating system, which cycles the tubs into the filling machine individually or places them on a conveyor belt. As a result, the machine operator does not need to re-load the packaging materials as frequently as a stockpiling time of up to 60 minutes is possible. Our systems are flexible and format-independent, from 0.5 kg to 12 kg.Your added value through miromatic stockpiling systems: Your operating personnel can be employed even more flexibly, because the system does not need to be permanently loaded with packaging materials. For one-track and two-track filling – filling possible during the production process Can be retrofitted to all miromatic filling systems Higher degree of automation and thus greater efficiency Lower workload for the machine operator Flexible system, aligned with your requirements Stockpiling of multiple stacks of tubs and lids

Request for a quoteResults for

Mechanical engineering - Import exportNumber of results

76 ProductsCompany type

Category

- Mechanical engineering - custom work (47)

- Import-export - mechanical engineering (20)

- 3D printers (5)

- Cables, high-voltage (5)

- Automation - systems and equipment (1)

- Goods handling systems, continuous (1)

- Cylinders, hydraulic (1)

- Fabrics for technical use (1)

- Measurement and regulation equipment and instruments - pressure (1)

- Steels and metals - machining (1)

- Vibrators, industrial - installations (1)

- Warehouse logistics (1)