- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- level monitoring

Results for

Level monitoring - Import export

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

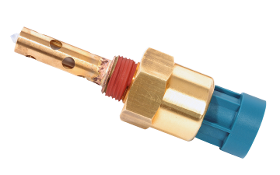

Areas of Application and Advantages BEDIA CLS 10 stands for special versions of our well-proven CLS 40 series for heavy duty applications. Currently, the BEDIA CLS 10 series includes a variety of sensors, which are compatible replacement parts for level switches from Cooper Standard and Robert Shaw which are obsolete nowadays – and this in well proven BEDIA quality. This also includes sensors with 2 complementary CMOS outputs. It should be emphasized that the water sensors with two complementary outputs can be operated with a supply voltage of 4.75 V DC – 32 V DC. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate (at a frequency of approx. 600 kHz). Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors react when a filling level is exceeded or falls below a limit. Aqueous mediums like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate. Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage. Types of Media The level monitoring sensors are designed for two different media types: For electrically conductive liquid media with relative permittivity within a range of εr 35 … 85 (water, coolant, water/glycol mixture) For electrically non-conductive liquid media

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Automated emptying system for containers up to approx. 30 liters ▪ Volumetric conveying progressive cavity pump based on the endless piston principle ▪ Pulsation-free and precise emptying and material supply to 1C and 2C dispensing systems ▪ In redundant dosing systems applicable ▪ For medium to high viscosity materials ▪ For structure sensitive, filled, abrasive materials ▪ Application for cylindrical or slightly conical metal and plastic containers ▪ Housing for machine safety and protection against dirt contamination ▪ Automatic retraction and venting the container as well as detection of media surface ▪ 4“-Touch panel with function keys for comfortable setting and parametrization of the system ▪ Externally controllable via Profinet interface ▪ Continuous determination of the position of the follower plate and level monitoring ▪ Adjustable pressure reduction for longer pauses

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA intelligent tank sensor ITS 65 is used to monitor the filling levels of oils of any kind. The sensor is able to automatically recognize and what kind of oil (hydaulic oil, engine oil etc.) is present and calibrates itself to it. The capacitative measurement principle permits measurement of levels without mechanically moving parts. This considerably increases stability and operating safety. Mechanics The new tank sensor ITS 65 is characterized by a particularly stable, but light mechanical system specially designed for “Heavy Duty Applications”. The mounting flange and measurement tube are constructed from die cast aluminium. This construction permits the insertion of tank sensors up to 1200 mm in length, without additional support on the tank floor. Analogue Output The analogue output is available as an voltage output with a range from 0 V to 10 V or as an PWM output.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA intelligent tank sensor ITS 60 is used to monitor the filling levels of Diesel fuels. The sensor is able to automatically recognize what kind of Diesel fuel (Bio-Diesel, Summer-/Winter-Diesel etc.) is present and calibrates itself to it. The capacitative measurement principle permits measurement of levels without mechanically moving parts. This considerably increases stability and operating safety. Mechanics The new tank sensor ITS 60 is characterized by a particularly stable, but light mechanical system specially designed for “Heavy Duty Applications”. The mounting flange and measurement tube are constructed from die cast aluminium. This construction permits the insertion of tank sensors up to 1200 mm in length, without additional support on the tank floor. The flange hole distribution is compatible with commercially used tank sensors. This means that this system can be used without expensive conversions.

Request for a quote

BDSENSORS GMBH

Germany

The slimline probe LMK 306 with ceramic sensor has been especially designed for the continuous level measurement at confined space conditions. Permissible media are clean or slightly contaminated water and thin fluids. Different cable sheath materials are available in order to achieve maximum media compatibility. Features: — nominal pressure: 0 ... 6 mH2O up to 0 ... 200 mH2O — accuracy: 0.5 % FSO — diameter 17 mm — excellent long term stability — suitable for hydrostatic level measurement e.g. 3/4" pipes — excellent linearity Optional Features: — different cable materials — customer specific versions e.g. special pressure ranges Preferred areas of use: — level measurement at confined space conditions — ground water monitoring — depth or level measurement in wells — drinking water abstraction — level measurement in open and closed tanks

Request for a quote

MKV METALL- UND KUNSTSTOFFVERARBEITUNG GMBH

Germany

By specially coordinating goods movements, LNG terminals, and shaker technology, even the smallest drill holes can be optimally flushed and coated. Specialized system technology ensures optimal layer thickness distribution, on both a micro and macro level. By continuously monitoring all process parameters, such as temperatures, flow rates, conductance, pH levels, shaker function, and processing time, we are able to achieve an error rate of almost 0 ppm.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Intelligent Storage Management With the ISM 400 you can flexibly store 7“, 13“ and 15“ reels, trays, tubes, printed circuit boards, well equipped feeder, solding pastes or screen printing frames manually and monitor their insertion and extraction. The different configuration possibilities of the ISM 400 satisfy the storage needs of the most varied types of components as well as operational and consumable resources of a modern SMT production. With the help of the optional humidity control module it is possible to constantly adjust and monitor the humidity level within the system.

Request for a quoteResults for

Level monitoring - Import exportNumber of results

11 ProductsCompany type