- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- inspection systems

Results for

Inspection systems - Import export

QUELLTECH GMBH

Germany

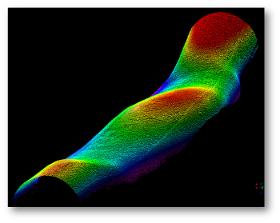

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote

QUELLTECH GMBH

Germany

The new QuellTech Q5 Laser Scanner Series combines the advantages of small form factors with both high resolution and scan rate. The sensor disposes of different set-up possibilities with respect to the analysis algorithm. Measurement results are delivered via Ethernet, calibrated in the X / Z plane. Special adjustable algorithms can be selected, extremely useful particularly also for optically most demanding surfaces. Time-consuming calibration tasks for the user are no more required, as the calibration routine runs on board. High Scan Rate with up to 14,000 Profiles per Second Due to an appropriate limitation of the image range (AOI) in X and Z direction, the scan rate could considerably be increased. High resolution and detection frequency with up to 14.000 profiles and 28 Mio. points per second •X measuring range from 10 to 1022 mm •Z measuring range (height) from 5 to 878 mm •Laser wave length blue 405/450nm, red 650nm

Request for a quote

MICRO-EPSILON

Germany

For the production of reeled resistors or sheet goods on roller head installations the thickness measurement is an essential factor for controlling and monitoring the production process. Applying systems of the RTP series, the profile thickness can be measured in various accuracy classes, thickness ranges and material widths.

Request for a quote

MICRO-EPSILON

Germany

The RTP 8302.T is based on the laser triangulation sensors and therefore ensures the measurement being independently from material constants. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. The system is ideal for monitoring high-dynamically processes due to its high measuring rate. The C-frame mechanics of the system disposes of an automated in-situ calibration in order to avoid interferences caused by temperature.

Request for a quote

MICRO-EPSILON

Germany

The system RTP 8301.EO operates according to a combination principle consisting of a thru-beam sensor, an eddy current sensor and a measuring roller. The eddy current sensor and the thru-beam sensor are applied on an innovative measuring clamp. Since the sensor measures the distance from the clamp to the roller, the lower side of the material is detected. As the sensor performance is specially aligned with the measuring task a huge measuring gap is possible while offering highest precision. The thru-beam sensor detects the upper side of the material. The thickness of the target is the difference between the two signals. The measuring clamp is equipped with a pneumatically cleaning mechanism and therefore ideal for the application in harsh environment. The profilometer corresponds to the TIP 8301 regarding its functionality. However, it has a different operators´ frontend and evaluation functions.

Request for a quote

MICRO-EPSILON

Germany

For the production of reeled resistors or sheet goods in calenders the thickness measurement is a vital factor for controlling and monitoring the production process. By applying systems of the RTP series, the profile thickness can be measured in various accuracy classes, thickness ranges and material widths.

Request for a quote

MICRO-EPSILON

Germany

The idiamCONTROL sensor system precisely measures the inner diameter of bore holes such as in extruders in order to determine the wear. The idiamCONTROL is guided into the bore hole and determines the bore hole diameter while being pulled out. Wear-based tolerance violations are automatically displayed and can be output via USB.

Request for a quote

MICRO-EPSILON

Germany

The FTS 8102.EC C-frame is based on the combisensor principle equipped with non-contact capacitive sensors. The distance between sensor and film is measured with the capacitive sensor. The eddy-current sensors ensures the thickness signal by a reference measurement to a second target. The system is designed as a C-frame and can be used as a traversing unit by using the linear axis.

Request for a quote

MICRO-EPSILON

Germany

The BTS 8101.EO O-frame is based on the combisensor principle. The system is equipped with a non-contact capacitive sensors and a Thrubeam sensor which are integrated in a traversing frame. The eddy current sensor measures the reference distance to the measurement roll‘s metal surface. The distance from the film surface is measured by the Thrubeam sensor. Together with the reference signal the film thickness is calculated. This combisensor principle allows extreme precise measurements.

Request for a quote

MICRO-EPSILON

Germany

The FTS 8101.EC O-frame is based on the combisensor principle equipped with non-contact capacitive sensors. The distance between sensor and film is measured with the capacitive sensor. The eddy-current sensors ensures the thickness signal by a reference measurement to a second target. The system can be integrated in the flat layer section.

Request for a quote

MICRO-EPSILON

Germany

The systems of the FTS familiy offer thickness measurements with extreme stability and accuracy. Applying them in extrusion lines provides reliable measurement results in high precision and thus creates the basis for controlling the production process and eventually the quality achieved.

Request for a quote

MICRO-EPSILON

Germany

The systems of the FTS familiy series offer thickness measurements with extreme stability and accuracy. Applying them in thermoformed flat film lines provides reliable measurement results in high precision and thus creates the basis for controlling the production process and eventually the quality achieved.

Request for a quote

MICRO-EPSILON

Germany

The systems of the FTS familiy series offer thickness measurements with extreme stability and accuracy. Applying them in extrusion lines provides reliable measurement results in high precision and thus creates the basis for controlling the production process and eventually the quality achieved.

Request for a quote

MICRO-EPSILON

Germany

Gauges and inspection systems from Micro-Epsilon are used in the plastics processing industry in order to ensure efficient production.

Request for a quote

MICRO-EPSILON

Germany

The demand for aluminum is constantly increasing due to its special technical properties. It can be made thinner and thinner as the strength increases. This is accompanied by tight manufacturing tolerances, which require measurement technology with more precision. As a manufacturer of measuring systems for the aluminum industry, Micro-Epsilon offers a comprehensive portfolio based on optical sensors without radioactivity that ensures More Precision in applications regardless of complexity and material properties. Optimized sensor technology tailored to the respective application, innovative mechanical design, as well as cooling and protection devices enable the systems to meet the needs of the processes. The high-performance signal processing and analysis software makes the systems the leading optical gauges on the market which detect the following parameters

Request for a quote

MICRO-EPSILON

Germany

Iron and steel represent a fundamental pillar in industrial production. Precision in the production process of metal plates, sheets and coils is crucial to the efficient use of scarce resources and economic success. As a manufacturer of measuring systems for the steel industry based on optical sensors, Micro-Epsilon offers a comprehensive portfolio without radioactivity that ensures More Precision in all applications regardless of complexity and material properties. With optimized sensor technology tailored to the respective application, innovative mechanical design, as well as cooling and protective devices, the systems meet the challenges of the processes. The high-performance signal processing and analysis software makes the systems the leading optical measuring systems on the market which detect the following parameters

Request for a quote

MICRO-EPSILON

Germany

For the steel and aluminum industry, Micro-Epsilon offers innovative measuring and inspection systems for thickness, profile and surface measurements. Performance and quality, as well as reliability of products and services have made Micro-Epsilon one of the leading suppliers of inspection systems for optical thickness measurement used in the metals industry. Our non-contact thickness measuring systems are used wherever high-precision thickness monitoring is required for control and quality assurance. Both in hot rolling mills, in continuous casting plants and in cold rolling mills and service centers, the Micro-Epsilon measuring systems operate reliably and with maximum precision. Numerous, successful installations in 13 countries around the world in milling lines and processing lines speak for themselves.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MICRO-EPSILON

Germany

The requirements for the dismantling parts are just as high as for the actual body. The surfaceCONTROL 2500 is used for the defect detection of attachments and interior parts. This enables the objective and reproducible identification and classification of defects. The surfaceCONTROL 2500 is used, for example, to inspect small parts such as fuel filler flaps, to detect defects on cockpit elements or for inspection in the press shop.

Request for a quote

MICRO-EPSILON

Germany

Micro-Epsilon tire uniformity and geometry machines measure force variation, runout, and sidewall appearance. Monitoring tire geometry i.e. the measurement of radial or lateral runout as well as side wall detection for bulges, constrictions, dents, week stamp etc., is the most important inspection at the end of the tire production process.

Request for a quote

MICRO-EPSILON

Germany

The dimensionCONTROL TWI 7303.I tire width inspection system is designed for profile width measurement in extrusion lines. This measuring system is based on camera vision technology involving two cameras inside one measurement box. These cameras are angle mounted to each other and operate according to stereo vision technology which enables high precision measurements in the whole calibration range.

Request for a quote

MICRO-EPSILON

Germany

For tire production, tread strips are cut from the extruded strip material. The system TLS 8303.I is applied in the extrusion line to measure the length of the strips immediately after the cutting machine in order to ensure a secure production process in high quality.

Request for a quote

MICRO-EPSILON

Germany

The system TCC 8303.I marks the running surface which is output after the extruder, inspects the colour lines for their completeness and measures the width of the running strip.

Request for a quote

MICRO-EPSILON

Germany

The profilometer thicknessCONTROL TCP8301.T-Offline is applied for sampling regarding the extrusion process of treads, side wall and inner liner material. The system offers measuring results in high precision and allows therefore an efficient production as well as a fully recorded quality control.

Request for a quote

MICRO-EPSILON

Germany

The profilometer of the thicknessCONTROL.TTP series accurately measures the thickness profile of tire tread or side walls during the extrusion process and enable therefore an efficient control during production as well as a fully recorded quality control.

Request for a quote

MICRO-EPSILON

Germany

During the production of inner liner, the thickness profile of inner liner material is measured immediately after the calender using systems of the thicknessCONTROL TIP series. Accurate precision of the non-contact optical system ensures high quality and security of the product produced. Sensors belonging to the thicknessCONTROL RTP series can also be applied for this application.

Request for a quote

MICRO-EPSILON

Germany

Monitoring tire geometry i.e. the measurement of radial or lateral unbalance as well as side wall detection for bulges, constrictions, dents etc., is one of the most important inspections at the end of the production process. The TGI 8302.LLT system can be easily integrated while offering precise measuring results.

Request for a quote

MICRO-EPSILON

Germany

The dimensionCONTROL TMWI 8302.LC system is suitable for the inline weight inspection of continuous running rubber profiles (tread pattern or sidewalls) for passenger and truck tires. Based on the force measurement principle, the inspection system uses two load cells which measure the deflection of the measurement conveyor. These sensor elements are attached to a massive construction, which ensures a long-term mechanical stability of the system. The measurement conveyor uses precise and balanced aluminum rollers with special surface treatment. This ensures a low deadweight, avoids influence of unbalance and eliminates material sticking. Data obtained from the load cells are processed in the implemented PLC cards which determine the measured weight mathematically.The software included offers a variety of measurement data processing, definition of design profiles, statistical analysis of measured profiles and diagnostic tools.

Request for a quote

MICRO-EPSILON

Germany

The rubber processing industry, as well as the tire production process is supported by Micro-Epsilon with a range of systems for inspection, monitoring and control of miscellaneous processes.

Request for a quote

MICRO-EPSILON

Germany

The requirements for the attachments are just as high as for the actual car body. The reflectCONTROL surface inspection system, familiar from car body inspection, has been adapted to the fast and high-resolution surface inspection of largely flat attachments. It recognizes and classifies the defects in an objective and repeatable way. Thanks to the large measuring field, trays can be measured in many cases in just a single capture.

Request for a quoteResults for

Inspection systems - Import exportNumber of results

44 ProductsCompany type