- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial equipment

Results for

Industrial equipment - Import export

WELTE CARDAN-SERVICE GMBH

Germany

Welte Cardan-Service GmbH has developed into a leading company in the cardan shaft industry since 1972. Thanks to our many years of experience in the repair and overhaul of drive shafts and cardan shafts, we guarantee a rapid maintenance process with short delivery times, always optimised in line with our quality standards. Our maintenance service enables you to carry out the repair of almost any cardan shaft quickly.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pad mounted valve with stainless steel body for safe shut-off of normal and aggressive media, for mounting on valve blocks.

Request for a quote

FLOTTWEG SE

Germany

The Flottweg Belt Press is in use in many mechanical separation technology areas, especially in the production of fruit juice, concentrate and vegetable juice. But other products, too, such as algae extracts, coffee grounds, herbal extracts, soy, and starch, are produced using belt presses. Flottweg Belt Presses: ►Maximum quality: You obtain not just the best possible quality, also maximum yield at lower costs. ►Minimum operating difficulty: Its clear design makes it easily accessible for cleaning, operation and maintenance. Automatic belt control provides optimum tension and guidance of the belts. ►Long-lasting design: The consistent use of stainless steel means that the belt press not only meets the requirements of strict hygienic standards, also is built tougher to last longer. ►Flottweg Service: We are at your side at any time with years of experience and comprehensive know-how.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated angle seat valve is the extremely reliable allrounder in valve technology and is predestined for very high switching capacities. In stainless steel design for neutral and aggressive media but also for a wide range of temperature applications suitable. The angled seat design offers a high flow rate.

Request for a quote

FLOTTWEG SE

Germany

Flottweg has developed a unique centrifuge concept especially for the high-level dewatering of sewage sludge: The Flottweg Xelletor series. For the wastewater treatment plant operator, dewatering offers enormous savings potential. The costs for transport and disposal of dewatered sewage sludge often account for 80% of the operating costs of mechanical dewatering. The dewatering performance of the Xelletor machine is significantly better than that of our predecessor models. And it's setting new standards in terms of throughput, dry substance, and polymer and energy consumption.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated globe valve type 7027 with integrated positioner for control applications with neutral to highly aggressive media. The straight design enables a highly efficient and very simple insulation of the valve body as well as the welded-on pipeline.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated globe valve type 7017 in stainless steel design for on-off applications with neutral to highly aggressive media. The straight design enables a high flow rate as well as a highly efficient and very simple insulation of the valve.

Request for a quote

FLOTTWEG SE

Germany

Proven know-how meets state-of-the-art technology. This is the best way to describe the new Flottweg decanter C series. We also have the optimal solution for the very large wastewater treatment plants. The combination of our own Simp Drive® drive system, which has been in use since 1994, and Recuvane®, which allows flexible and simple retrofitting as well as targeted discharge of the centrate water, sets new standards for Flottweg in separation technology.

Request for a quote

FLOTTWEG SE

Germany

Flottweg C series decanters around the world process 25 million liters of sewage sludge per hour. The dewatering and thickening of sewage sludge plays a decisive role in the wastewater treatment process. Requirements for the quality and efficiency of sewage treatment plants increase year after year, not least driven by the increasing costs of energy and disposal. As a result, the state of the art is now to use decanter centrifuges to dewater and/or thicken the incoming sludge. Flottweg developed the decanters of the C series especially for this purpose. The C7E represents the largest of all the C machines. The C7E increases the proportion of dry substance in the sludge, thereby reducing its volume and weight (due to loss of water). That means that operators need to dispose of, recycle, or burn less sludge. The result: enormous potential savings for the operators of sewage treatment plants.

Request for a quote

FLOTTWEG SE

Germany

Innovationen sind Flottweg Spezialität. Unsere Xelltorbaureihe spiegelt Erfindergeist, langjährige Erfahrung und technisches Know-How in einer Maschine wieder. Auf Kläranlagen ausgelegt ist die X5E für mittelgroße Kläranlagen die optimale Lösung, wenn es um Schlammentwässerung und Schlammeindickung geht. Die Kosteneinsparung hinsichtlich Entsorgung und Transport ist für viele Kläranlagenbetreiber der ausschlaggebende Punkt, sich für den Flottweg Xelletor zu entscheiden.

Request for a quote

MESUTRONIC GMBH

Germany

TUNNEL METAL DETECTOR WITH INTEGRADTED EVALUATION ELECTRONIC -USED IN BELT CONVEYORS FOR QUALITY CONTROL OR MACHINE PROTECTION. Detects all metals encapsulated or as loose parts. The new performance benchmark! imagePHASE visualizes your product and is a synonym for highly accurate metal detection at maximum reliability. Impressive simple operation. Minimal floor space required (reduced metal-free area) due to mesuCAGE technology. Compliant with quality assurance according to HACCP, IFS, BRC, SQF. Specifically tailored system solutions with reliable conveying technology and selected accessories.

Request for a quote

FLOTTWEG SE

Germany

Honored with the German Innovation Award 2019, the Xelletor series is one of the greatest achievements in the field of sewage sludge. Dewatering sewage sludge is standard for wastewater treatment plants and since it usually has to be transported away, operators have an interest in separating as much water as possible from the sludge. This saves weight and thus reduces costs. Savings of up to 10% in sludge volume and 34% in energy consumption are possible. Our Xelletor high-performance centrifuge inspires customers all over the world with the many years of technical know-how and innovative spirit behind it.

Request for a quote

FLOTTWEG SE

Germany

Flottweg nozzle separators (2- and 3-phase nozzle separators) are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. The product to be clarified or separated flows via a stationary inlet pipe into the inside of the bowl and is gently accelerated to operating speed by the distributor. Characteristics of our nozzle separators: — Energy-optimized and low-wear bowl design — High performance — Simple and fast maintenance — Designed for perfect hygiene The Flottweg nozzle separators are available in two basic designs: — Clarifier / 2-phase nozzle separator — Concentrator / 3-phase nozzle separator

Request for a quote

FLOTTWEG SE

Germany

Flottweg nozzle separators (2- and 3-phase nozzle separators) are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. The product to be clarified or separated flows via a stationary inlet pipe into the inside of the bowl and is gently accelerated to operating speed by the distributor. Characteristics of our nozzle separators: — Energy-optimized and low-wear bowl design — High performance — Simple and fast maintenance — Designed for perfect hygiene The Flottweg nozzle separators are available in two basic designs: — Clarifier / 2-phase nozzle separator — Concentrator / 3-phase nozzle separator

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hygienic angle seat control valve type 7025 with integrated digital positioner is specially adapted for use in the food and beverages production. Suitable for controlling product streams, drinking water, CO2, nitrogen as well as sterile steam and sterile air. All wetted plastics are FDA-compliant and conform to EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. The hygienic angle seat valve is also certified to Technical Instructions on Air Quality Control (TA-Luft) in accordance to ISO 15848-1 and on request can be supplied with an acceptance test certificate in accordance with EN10204 3.1.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hygienic angle seat valve type 7015 is ideal for applications in food and beverage production. The valve can be used to shut-off product streams, drinking water, CO2, nitrogen as well as sterile steam and sterile air. All wetted plastics are FDA-compliant and conform to EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. The hygienic angle seat valve is also certified to Technical Instructions on Air Quality Control (TA-Luft) in accordance to ISO 15848-1 and on request can be supplied with an acceptance test certificate in accordance with EN10204 3.1.

Request for a quote

FLOTTWEG SE

Germany

Flottweg nozzle separators (2- and 3-phase nozzle separators) are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. The product to be clarified or separated flows via a stationary inlet pipe into the inside of the bowl and is gently accelerated to operating speed by the distributor. Characteristics of our nozzle separators: — Energy-optimized and low-wear bowl design — High performance — Simple and fast maintenance — Designed for perfect hygiene The Flottweg nozzle separators are available in two basic designs: — Clarifier / 2-phase nozzle separator — Concentrator / 3-phase nozzle separator

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The dispenser based on the ViscoTec endless piston principle is particularly suitable for the filling, dosing or application of viscous, abrasive, highly filled or shear-sensitive materials. There are three different versions of the volumetric dosing system: 3VHD8, 3VHD12 and 2VHD12. Important key data: - Withdrawal option (no dripping or thread pulling) - absolutely linear relationship between rotor speed and spread rate - long service life due to media-specific component selection - quick and easy disassembly/assembly - Sealless, easily dismountable rotor string - process-safe and high-precision filling/dosing - variable quantities infinitely adjustable - compact construction Hygienic features: - Design according to EHEDG guidelines - FDA-compliant design/development - hygienic and pharmaceutical design - Interior with optimised dead space - all surfaces Ra ≤ 0.8 μm - rinsing connection for automatic cleaning

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The pneumatic flanged sliding gate control valve type 8621 in GS3 design with integrated positioner designed according to ASME B16.34, API RP 553, API 598, ASME B31.1 and ASME B31.3 incl. flange connection according to ASME B16.5 is suitable for a wide range of process applications. Media such as steam, liquids, gases, etc. can be handled perfectly.

Request for a quote

FATH GMBH

Germany

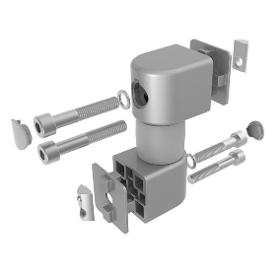

Description: Connection joint with friction for the creation of system arms using profile pieces; pivotable 360°; friction joint can be attached lateral, transverse, or on the face of the profile; if attached on the front face, the core hole of the respective profile must be M8 threaded (min. 15 mm deep) Material: Housing: Aluminum die-cast Cover ring: Plastic Inserts: Steel Friction shaft: Steel Cover caps: Plastic Screws: Steel Washers: Steel Centering plates: Aluminum die-cast T-slot nuts: Steel Surface: Housing: Laquered Centering plates: Laquered Screws: Zinc plated Washers: Zinc plated T-slot nuts: Zinc plated Color: Housing: Alu color Cover ring: Gray ≈ RAL 7042 Cover caps: Gray ≈ RAL 7042 Centering plates: Alu color Set: Various Sets available - Please contact us for Details Pack Quantity: 1 piece/set

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

The HELIO®MAT dryer station is part of the JETBOXX® system and features an independent JETBOXX® dryer with full functionality at each individual docking station. The material can be predried in removable drying containers at the dryer station. The drying container can be removed and brought to the processing machine if needed. It will be attached directly onto the feeding section there and the dried material can be processed. If the material should be kept dry on the machine, a JETBOXX® docking plate with dryer control are used in addition. HELIO®MAT is applicable for example as pre-drying station for quick material change, as dryer station for sampling batches, for batch drying for small quantities / sampling, for laboratory applications, or for cleanroom supply with hermetically sealed dry material containers. Material change without delay. No humidification. No cleaning issues.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

The JETBOXX® mini top-mounted dryers are particularly applicable where small material flow rates with the highest drying precision are required. Due to their compact design, the plastic granulate dryers can be mounted on the feed section of the injection molding machine without any difficulty. The dryers are available with a volume of 0,5/1,0/2,5/5/6/12/18 litres and can be optimally adapted to your requirements with a large number of options from the JETBOXX® system. Compressed air conveyors of one or two components with or without dedusting function are available. Filling by hand is also possible via hinged covers. The compressed air-based dryers are maintenance-free and provide professional functions such as: plastic-specific and throughput dependent dryer settings, database for plastics, conveying control, week timer, overheating protection, dew point measurement, speed dial programs, personal programs, and many more.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

HELIO®Clean 3 is a combined conveying-/ mixing-/ and dedusting device for virgin material and regrind. The dust is removed through a 3-stage dedusting system with ionisized air. The compact design makes it ideal for mounting on the feed zone of the processing machine or on a drying container. Available in 1- or 2-component version, filling is carried out by the integrated compressed air conveying technology with Venturi suction lance(s). Dedusting capacity up to 25 kg/h. Quality: Dust in granules causes lowered mechanical properties of technical plastic resins, leads to problems with surface finish in case of transparent parts, to high rate of rejects basing on smudges or white/black dots in transparent injection moulding parts like for example optical lenses of PC and PMMA. Professional cleaning of resins brings the quality to the original state again and optically perfect parts can be produced.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

JETBOXX® plastic granulate dryers are compressed air based dry-air dryers for mounting directly on the feed section of the processing machine. The JETBOXX® technology guarantees perfect drying results thanks to plastic-specific and throughput-dependent dryer settings. The dryers are available with a volume of 30/50/75 litres and can be optimally adapted to your requirements with a large number of options from the JETBOXX® system. The JETBOXX® control provides a database for plastics, conveying control, week timer, fully automatic decrease and resume of the drying intensity when production is interrupted (overheating protection), automatic restart with preheating program in 1- or 2 shift operation, dew point measurement, speed dial programs, personal programs, and many more. Compressed air conveyors of one or two components with or without dedusting function are available. The conveying control is already included.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

HELIO®Clean 2 is a combined conveying-/ mixing-/ and dedusting device for virgin material and regrind. The dust is removed through a 2-stage dedusting system. The compact design makes it ideal for mounting on the feed zone of the processing machine or on a drying container. The separated dust content is sucked out into an external collection bin. Available in 1- or 2-component version, filling is carried out by the integrated compressed air conveying technology with Venturi suction lance(s). Quality: Dust in granules causes lowered mechanical properties of technical plastic resins, leads to problems with surface finish in case of transparent parts, to high rate of rejects basing on smudges or white/black dots in transparent injection moulding parts like for example optical lenses of PC and PMMA. Professional cleaning of resins brings the quality to the original state again and optically perfect parts can be produced.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

Mobile plastic granules dryers from the JETBOXX® system are available with a volume of 30/50/75/200 litres and can be optimally adapted to your requirements with a large number of options. They can be used anywhere, where top-mounted dryers fail because of weight / or space reasons, and flexibility is required. When changing the setting of task, the components can be combined easily or used for example as top-mounted dryers. The compressed air-based dryers are maintenance-free and provide professional functions such as: plastic-specific and throughput dependent dryer settings, database for plastics, conveying control, week timer, overheating protection, dew point measurement, speed dial programs, personal programs, and many more.

Request for a quote

WECKERLE MACHINES

Germany

Weckerle´s FlexFill facilitates to fill a wide range of cosmetic products such as mascara, lip gloss, liquid liner, deodorant sticks, nail polish, etc. Furthermore, this machine offers the possibility to fill into a variety of packaging with different volumes and diameters. Therefore, absolute process control and highest flexibility is ensured. Output: up to 10800 pcs/h Linear filling process

Request for a quote

WECKERLE MACHINES

Germany

The MultiStick is able to tailor up to 6 different forms and capable of filling up to 6000 lipsticks per hour in 24/7 operation. Thanks to the new Plug & Play Technology with the rail mounting system for process stations, the machine can be easily upgraded without major frame rework. It also offers an optimized footprint with integrated compounding. The MultiStick assures the ultimate process flexibility in the whole filling technology.

Request for a quote

WECKERLE MACHINES

Germany

Weckerle´s new Dry Powder Compacting Line complements the successful range of powder machines. The DPC assures dosing and pressing of various dry cosmetic powders, such as eye shadows and different kinds of face powders with an output up to 2,100 pcs/h. Through the integration of an automatic extraction system, a hygienic process is ensured. The servo-driven pressing station guarantees an easy adjustment of several parameters in correlation with your powder compound behavior to your specific requirements. Also an easy filling height adjustment is included. Each specific production set-up is available directly in the HMI. The user friendly designed machine is able to cater a wide range of formats and provides accurate pouring with perfect product surfaces. State of the art SMED designs enable product and format changes in just a few minutes.

Request for a quoteResults for

Industrial equipment - Import exportNumber of results

36 ProductsCompany type

Category

- Cosmetics industry - machinery and equipment (10)

- Food industry - machinery and equipment (9)

- Industrial valves, operating equipment (8)

- Plastics - industrial machinery and equipment (6)

- Water treatment, industrial - systems and equipment (5)

- Food Industry - Machines & Equipment (1)

- Pharmaceutical industry - machinery and equipment (1)

- Beverage industry - machinery and equipment (1)

- Repairs - industrial equipment (1)