- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flange connection

Results for

Flange connection - Import export

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The pneumatic flanged sliding gate control valve type 8621 in GS3 design with integrated positioner designed according to ASME B16.34, API RP 553, API 598, ASME B31.1 and ASME B31.3 incl. flange connection according to ASME B16.5 is suitable for a wide range of process applications. Media such as steam, liquids, gases, etc. can be handled perfectly.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated angle seat flange valve for high switching powers. In stainless steel design also suitable for neutral and aggressive media. The angled seat design offers a high flow rate, the flange connection offers easy installation. Flange acc. to DIN EN 10921 Flange acc. to ANSI #150, ANSI#300 Limit switch Pilot valve Manual override . . .Piston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuatorLow temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

BILLI DICHTUNGSTECHNIK GMBH

Germany

The function of gaskets is to prevent the leakage of medium outside the equipment. Static seals are used in many applications such as plumbing and heating systems, sealing fasteners, containers and pipeline construction. They are washers, rings or frames which generally are adapted to the whole width of the sealing surface. They can be used for example in flange connections of pipelines, pumps, motors, valves, etc. The gaskets are made of various materials such as: Rubbers, fiber plates, synthetic plates, graphite, PTFE, etc.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembly lubrication of machine parts, screw connections, fittings, flange and plug-in connections, guides, sliding and sealing surfaces of ovens, boilers, burners, motors, engines subject to high-temperature conditions Separating paste Advantages and benefits Excellently suited for preventing seizing and burning together Highly effective due to outstanding separating action and pressure absorption Good protection against ingress of splashing and condensed water Free of heavy metal compounds Good corrosion protection Excellent water resistance Wide operating temperature range Optimum ratio of screw tightening torque to achievable pre-tension

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatic control valve with angle seat design. The angle seat design offers a high flow capacity, the flange connection an easy installation. The integrated digital or analogue positioner is coming along with a very compact design. All wetted parts are made from stainless steel. Flange acc. to DIN EN 10921 Flange acc. to ANSI #150, ANSI#300 Digital positioner type 8049 Pneumatic and electropneumatic positioner type 8047 Positioner with integrated process controller type 8049 IPC Positioner type 8047 and type 8049 also in explosionproof versionPiston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuator Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Piping and hoses, for example steel bottles, compressors, breathing devices, oxyacetylene gas and inert-gas arc welding devices and burners Fittings, flanges, valves, screwed connections, soldered and welded connections of pressure gas systems and lines Suitable for compressed air, refrigerant, acetylene, butane, natural gas, carbon dioxide, gaseous oxygen, propane, town gas, nitrogen, hydrogen and, ammonia Advantages and benefits Acts non-corrosive Allows direct visual inspection of the leakage point through bubble formation Tested by the DVGW in accordance with DIN EN 14291 Suitable for spraying overhead

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembly lubrication of machine parts, screw connections, fittings, flange and plug-in connections, guides, sliding and sealing surfaces of ovens, boilers, burners, motors, engines subject to high-temperature conditions Separating paste Advantages and benefits Excellently suited for preventing seizing and burning together Highly effective due to outstanding separating action and pressure absorption Good protection against ingress of splashing and condensed water Free of heavy metal compounds Good corrosion protection Excellent water resistance Wide operating temperature range Optimum ratio of screw tightening torque to achievable pre-tension Also available as spray version OKS 2351 For best adhesion, clean contamination and other lubricants from thread and slide surfaces. Best way is to clean mechanically first (for example, with a wire brush) and then with OKS 2610/OKS 2611 universal cleaning agent. Apply sufficient OKS 235

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

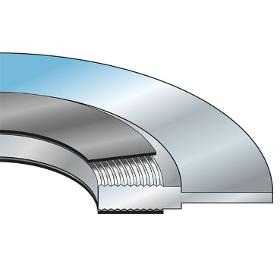

D 7 ProCor Camprofile Gasket, Rip profiled metal base covered with graphite or PTFE, optional with or without center ring(s). 1] pay attention to the temperature limit of PTFE Characteristics For flange connections in high pressure piping and in fittings Extremely low leakage values with PTFE inlay. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance up to 550 °C with graphite inlay Technical parameters Covermaterial PTFE Temperature range: -200... +260 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 Covermaterial Graphit Temperature range: -200... +500 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 1] pay attention to the temperature limit of PTFE Main application For all flanges inside the main traction line High level of temperature and pressure resistance Suitable for Power plants Petrochemical...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

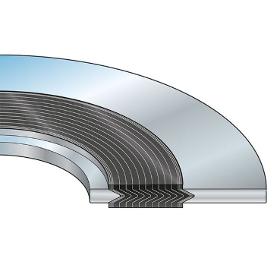

Spiral wound gasket made of crimped metal tape with sealing wraps of non asbestos gasket material. Optional: inner and/or outer metal ring. Characteristics For flange connections in high pressure pipe line construction and fittings Extremely low leakage with PTFE spiral. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance to 550 °C with graphite spiral Media resistance: pH 0 - 14 Max. pressure load: p = 400 bar Temperature range: t = -200 to +550 °C Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C Pressure: p = 400 bar Main application High temperature and high pressure flanges Piping Pressure vessels Heat exchangers Fittings Suitable for Power plants Petrochemical plants Chemical industry Material Centerring ring OD: Carbon Steel galvanized Spiral: 316L Centerring ring ID: Carbon Steel galvanized Other material combinations on request Product Types SF 11 Spiral wound gasket without any center ring for flanges with tongue and groove connection SF...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High temperatur sheet gasket from expanded graphite with stainless steel foil reinforcement Characteristics One layer of 0.05 mm stainless steel carrier (3 mm thickness 2 layers) with graphite on both sides fixed by a special only 10 µm thick adhesive coating. Purity 98 % Practically no cold flow or creep under temperature Excellent in use at cycling temperatures Very good sealability even at low gasket stress. Technical parameters pH 0 - 14 Temperature: t = -250 … +550 °C, in oxidizing atmosphere 450 °C Pressure: p = 40 bar Main application Suitable for sensitive flange connections Housings of pumps and fittings Suitable for In all industries Approvals BAM DVGW Variant Economic grade alternative D 5.2 with 0.05 mm stainless steel foil reinforcement Form of delivery Gasket sheet size of 1,000 x 1,000 mm in der Dicke 0.55 / 0.75 / 1.0 / 1.5 / 2.0 / 3.0 mm or cut gaskets according to drawing, or EN and international Standards. Special dimensions on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Gasket Sheet of Expanded Graphite, both sides with impregnation Characteristics Soft and extremely adaptable non reinforced graphite sheet with a purity of 99.85 %. Special coating on both sides raises sealabilty. Practically no cold flow or creep under temperature. Non hardening Excellent in use at cycling temperatures Excellent sealability even at low gasket stress. Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C, in oxidizing atmosphere 450 °C Pressure: p = 40 bar Main application Sensitive Flange connections like sight glasses, glass- or glass lined flanges in all industries. Suitable for In all industries Approvals BAM DVGW KTW Variant Economic grade alternative D 5.0 on request. Form of delivery Gasket sheet size of 1,000 x 1,000 mm in thickness of 1.0 / 1.5 / 2.0 mm or cut gaskets according to drawing, or EN and international Standards Special dimensions on request.

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• for standardized interface connection DIN - EN - ISO 9409 - 1 • two-part connection flange • compact design • Torque range: 40 - 1800 Nm • shaft diameter: 12 - 90 mm • simple installation with radial EASY-clamping hub at output side

Request for a quoteResults for

Flange connection - Import exportNumber of results

13 ProductsCompany type