- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electrical components

Results for

Electrical components - Import export

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

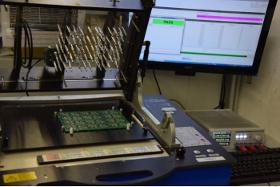

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. This electrical test process is ideal for testing smaller numbers of units, such as for pre-production, prototype or pilot series. The rapid test creation process allows, among other things, flexible reaction to product changes. Flying probe tests can be rapidly set up and are cost-efficient.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. In our test laboratory, we are able to carry out static and cyclical environmental simulation for you, from air-to-air and liquid-to-liquid thermal shock tests to storage temperature and humidity tests. Based on the environment in which the product is to be deployed, we will draw up a tailor-made quality assurance programme. Through simulation of the conditions that cause ageing (e.g. large temperature fluctuations) we can ensure that the product will reach the required service life. Products are also subjected to further customer-specific tests in fields such as EMC, overload resistance and mechanical loading.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. For components of the most varied shapes and with diverse electronics components, we will set up our AOI stations according to individual needs and provide reliable optical control of the overall assembly. Automatic optical inspection of your components is naturally part of our service range.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. PRUFREX is a manufacturer of test systems and software. In close collaboration with our own test equipment developers, we manufacture beds of nails for the in-circuit test (ICT) and functional test (FCT), alongside test equipment and production aids. Using the entire range of available test procedures, we will develop a strategy that suits your product.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Smart automation concepts enable us to meet the highest standards of manufacturing. Our products are manufactured in Germany and made in USA, in a cost-efficient manner. Benefit from our production expertise that has been continuously developed over many decades. Mechanical protection, reliable electrical insulation, moisture shielding and heat dissipation - with continuously optimized potting resins (polyurethanes, epoxies, etc.) and potting equipment, PRUFREX is a leader in the field of vacuum potting. When it comes to the safe protection of your electrical and electronic components, our state-of-the-art, automated manufacturing equipment meets all contemporary requirements. The use of specially adapted epoxy and polyurethane potting compounds ensures excellent potting characteristics and the best-possible impregnation of components and coils. These optimised potting compounds also contribute to optimal heat dissipation.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Component placement requires individual approaches. Our range of solutions covers small series produced by hand, medium-size series using semi-automated wave soldering machines and fully automated production lines for large-scale manufacture. We adjust the level of assembly automation to your project – so that you achieve the best result both economically and technically.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Whether it's manual soldering with robotic support, wave and selective soldering or laser soldering – in all assembly tasks, we are able to use any technique required without a problem. Depending on the component, different soldering technologies offer different advantaged. We will adjust the process individually to your project.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). At PRUFREX, single-chamber and multi-chamber coils can also be achieved using two-wire windings. For specific magnetic flux requirements, we apply wires of different thicknesses to the coil form. Two different wire thicknesses, from 0.045 to 0.71 millimetres, on coil forms with press-in ferrite or metallic cores.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). We can wind onto any desired coil form using many different press-in ferrite and metallic cores. Multiple tap coils are also possible. Pins are automatically applied to the coil connections during the winding process, with wire drawing electrically controlled. Our winding machines handle single-chamber and multi-chamber coils with wire thicknesses from 0.045 to 0.71 millimetres.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). To manufacture self-supporting coils, we use self-bonding wire. During winding, the surface of the wire is bonded using hot air. To ensure the coil connections can be soldered, they are then stripped of insulating enamel using a fully automated milling process. PRUFREX is able to make air core coils with wire thicknesses from 0.045 to 1.6 millimetres.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. The 3D automatic optical inspection of SMD components combines 2D and 3D inspection at maximum speed. Some of our machines allow an inspection in 360 ° steps. Depending on the machine, excellent dynamic properties and the highest positioning speed can be achieved on the basis of linear drives.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Dispensing technologies allow us to adjust your components to additional requirements. Our range of services covers all dispensed materials, from adhesives through heat-conducting pastes to silicones. Depending on your project requirements, we offer you the most efficient routes to implementation – from manual production to CNC cells.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Placement tests, checking the electrical and software functionality, launch tests – depending on your individual requirements and your component, we will develop a test strategy and tune the tests to fit with each other. Our comprehensive test development methodology accelerates processes running all the way to the delivery of your product and reduced testing costs.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

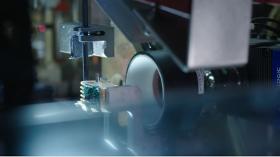

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. So you want to achieve compact shapes for complex components? Our test and programming service is there for you. The system we use keeps line contact high, offers perfect access and ensures precise bonding. The advantages for you: flexible program selection until shortly before the start of production, no extra expenditure for external programming.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

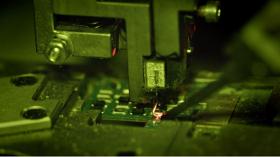

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. High-performance placement machines by ASM with short setup times and high flexibility form the backbone of our automated SMD placement systems. Our services also include assembly of THR components (pin-in-paste technology). Extensive monitoring systems and built-in cameras ensure high precision in the placement process.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

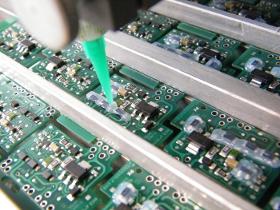

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. Printing the soldering paste takes place using the latest soldering paste stencil printers. They are so exact that even the tiniest elements can be precisely placed. The faultless print result is reliably assured with a 3D paste inspection.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

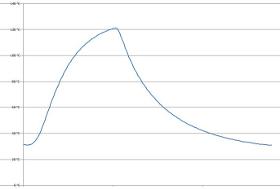

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. We have the latest generation Rehm reflow soldering systems. In particular with regard to temperature zones, they are exceedingly efficient. The soldering process takes place in a protective atmosphere. In the reflow soldering process, we process through-hole and SMD components. The number of work stages, sources of error and thermal loads is reduced. In the reflow process we are also able to solder through-hole components, thereby reducing sources of error and repeated thermal load and work stages.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. When planning tests, we work to your test specifications or develop a cost-optimised, efficient concept. In our tests, we simulate real usage conditions. In this way, we make sure that devices, systems or components will function correctly. Quality management at PRUFREX also includes developing efficient testing strategies.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Based on your ideas and in close collaboration with your specialists, PRUFREX takes part in the development of your new products. Our deeply ingrained processes and long-term supplier relationships allow us to realise both test series and A B and C models with great rapidity. We will produce the functional models and later series on identical machinery.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

The electromagnetically compatible design of a system, from first sketches through creating the circuit diagrams all the way to EMC-optimised routing on the circuit boards, allows the creation of a robust electrical product that will still function reliably even under difficult conditions. As specialists in ignition systems, we know the sources of electromagnetic disturbance and are world leaders in EMC processes.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

Careful planning and many years of experience are necessary to build functional and reliable switchgear in the long term. We take over the entire conceptual design of control cabinets: from electrical planning with EPLAN P8 through the complete procurement of high-quality components to assembly. IFA Technology generally works according to EN/DIN/VDE standards and with the latest electrical components. We are UL and UL-NRBX certified for plants and systems located in North America. We create an E-P&ID diagram for each plant or system. This makes the relationship between electrical and mechanical components transparent and simplifies maintenance and troubleshooting. Our circuit diagrams are drawn up in accordance with the VDE0113/EN-60204-1 directives or - for the North American market - in accordance with the NFPA79 and UL508A directives. The electrical documentation is available in all common foreign languages.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For fast determination of thermally-dependent interruptions in electrical circuits or components Avoidance of heat damage when soldering electrical components For heat protection of neighbouring components Shrinking of inner parts for removal of seized taper plugs, pins, plugs or bearing bushes Generation of shrink seats for assembly of inner parts For rapid temperature adjustment during materials testing For simulation of cold-starting conditions with motor-vehicle automatic starting systems Advantages and benefits Highly effective due to outstanding undercooling effect Excellently suited for simple cooling of parts Immediate cooling of smaller surfaces or parts down to –45°C depending on spraying duration Evaporates very quickly without residues Also provides good cleaning effect No negative affects on plastics and insulating materials

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Electrical cabinets contain the electrical and electronic components of a process engineering system, a machine tool, or production equipment that is not directly located in the machine. They are manufactured by special switch cabinet builders or by the machine manufacturers themselves. To save costs, there are automation solutions that are not only worthwhile for large production series, but are also suitable for the more efficient and economical production of individual and small series. Metzner offers a unique and comprehensive system solution to reduce your expenses in switchgear construction. Depending on your requirements, different stripping and crimping machines are available, which differ in terms of design, performance and degree of automation. METZNER TRIATHLON SERIES - for precise cutting to length and one- or two-sided stripping - for crimping the ferrules (single- and double-sided) - for individual labelling of strands with different printing method

Request for a quote

ALPHA LASER GMBH

Germany

Suitable also for welding precision mechanical parts and medical technology components as well as for the manufacture of sensors and electrical components The ALS 100 is an ergonomic workplace The spacious work chamber offers a very brightly lit work area and is loaded via two side doors. The average power of 100 W enables a fast pulse sequence (up to 25 Hz) and thus fast work even at high energy settings. The homogeneous fusion of the materials results in welding results of the highest quality. The laser is used in the manufacture and repair of jewelry, in precision engineering or when welding sensors

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

Vibrating tables suitable for testing and quality inspection of sensitive components The vibratingsystems are employed for simulation of stress created by mechanic vibrations on mechanical and electrical components and subassemblies with the following features: Direction of oscillation: linear - horizontal (sinusoidal oscillation), adjustable by means of a selector. Either oscillation in x-axis or alternatively in y-axis

Request for a quote

NORIS GROUP GMBH

Germany

Limit value switch for frequency (sinusoidal signal). Simple application; for rough environments. Limit value freely adjustable by drum scale. Open-circuit or closed-circuit devices available. Compact and robust construction. Operating status indication by integrated LED.

Request for a quote

NORIS GROUP GMBH

Germany

I/O slave module with 24 digital inputs and/or outputs Robust design for harsh environments All channels short-circuit proof Ideal for use in shipbuilding thanks to approvals from classification societies

Request for a quote

NORIS GROUP GMBH

Germany

I/O slave module with 16 digital inputs and 8 relay changeover outputs Robust design for harsh environments Ideal for use in shipbuilding thanks to approvals from classification societies

Request for a quote

NORIS GROUP GMBH

Germany

I/O slave module with 32 digital inputs Robust design for harsh environments Ideal for use in shipbuilding thanks to approvals from classification societies

Request for a quoteResults for

Electrical components - Import exportNumber of results

54 ProductsCompany type

Category