- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ejectors

Results for

Ejectors - Import export

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

OKS 4240 is a special grease for the lubrication of ejector pins in the plastics industry. Lubrication of ejector pins in the plastics industry at high temperatures and slow movements Lubrication of rolling and friction bearings at extremely high temperatures and aggressive operating conditions Advantages and benefits Extraordinarily good resistance to vapours occurring during plastic processing Good plastic and elastomer compatibility Excellent temperature resistance Lowest evaporation losses, also at high temperatures ensure long regreasing intervals Good media resistance Also suitable for fast-runing bearings thanks to low share of solid lubricants

Request for a quote

SPIROL

Germany

SPIROL's Series 880 Coiled Spring Pin was designed specifically for use as the hinge pin for PC board card lock and ejector clip mechanisms. The quality of the hinge is unsurpassed by other fastening methods due to the low insertion force and compression of the pin during and after installation. As with all Coiled Spring Pins, the Series 880 hinge pin for PC board card locks and ejector clips is self-retaining, and thus no secondary processes are required for retention. The Coiled Pin's uniform radial spring force results in a controlled hinge movement that remains consistent throughout the life of the assembly.

Request for a quote

IBG HYDROTECH GMBH

Germany

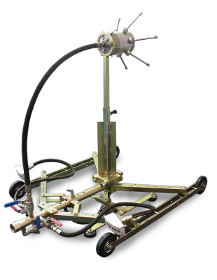

The GP 150 consists of a modular cage system with variable width and height for large profile channels (circular, egg, box profiles as well as profiles with dry weather channel). It is designed to enable the user to process a corresponding profile size with as few components and assembly work as possible. With only five plug-in connections and three screw connections, a maximum body size of DN 4,000 can be achieved.

Request for a quote

IBG HYDROTECH GMBH

Germany

The PowerJet series with single or double jet is particularly suitable for cleaning water-bearing pipes and ducts. The increase in working performance with low energy input is due to the novel implementation of the available performance variables such as pressure and volume flow. Even with a volume flow of 280 l/min. and 130 bar, large quantities of loose material (stones, sand, sludge and paper/cellulose) can be transported efficiently. This cleaning method also makes it easy to maintain and preserve old sewer systems (the latter is in line with municipal requirements). Any industrial water can be used to drive the system. The use with water recovery is problem-free.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Nash has been designing, manufacturing and troubleshooting steam jet air ejector systems since 1986. Steam ejectors provide vacuum in many process industries and utility companies. Combining low capital cost, simple operation, high reliability and the ability to handle large volumes at very high vacuum levels, they can be optimized to contribute to process enhancement and operational efficiency.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Steam Ejectors & Liquid Ring Vacuum Pumps Engineered for optimum efficiency, Nash Hybrid Systems now offer a 15% reduction in steam consumption. This was achieved through extensive R&D efforts, resulting in innovative design improvements. Nash has designed and manufactured hybrid systems since 1979, and our hybrid systems are recognized worldwide for reliable performance and low greenhouse gas emissions. As the new standard for Nash hybrid designs, these systems maintain traditional benefits, while offering accelerated payback through increased energy savings, condensers designed per HTRI specifications and a faster response time through regional sourcing. Nash is the only company to manufacture both the pumps and ejectors that go into a hybrid system, and offers a complete system warranty. All Nash hybrid systems are backed by global aftermarket support, decades of engineering expertise, and a proven history of reliable, dependable installations. Existing all ejector systems can be upgraded to more efficient hybrid systems by replacing or modifying stages. Nash engineers can evaluate your specific systems and recommend a custom hybrid design that will optimize your energy savings. Through reduced operating costs, upgraded systems can offer a payback of 2 years or less. Nash hybrid systems are used in industries and applications where deep vacuum is required and system reliability is critical. In operations where efficiency is key, emissions are a concern, or if there is a scarcity of steam in the plant, Nash hybrid systems are the optimal solution for efficiency.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Ejectors - Import exportNumber of results

6 ProductsCountries

Company type