- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cylinder heads

Results for

Cylinder heads - Import export

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

1.Standard Equipment DP1 Valve Leak Detector including a set of seven adapter plates, a flexible extension hose and a sturdy storage case. 2. Working Principle Applying an air pressure of about 6 bar to the DP1 Valve Leak Detector results in a max. vacuum of about 850 mbar which is applied via an adapter plate to the inlet or exhaust port of the cylinder head to check the respective valve for leakage. The vacuum gauge at the DP 1 indicates the tightness of the valve.

Request for a quote

VOXELJET AG

Germany

• Mold measurements up to 4 x 2 x 1 m • Does away with elaborate and expensive mold set-ups • Short throughput time (a few days) • Sand molds correspond 1:1 with CAD model • Structures can be designed in accordance with requirements, without having to watch for draft angles or undercuts • Special sands prevent casting problems • Surface quality can be adjusted through use of different sands • Coarse-grained sands for high gas permeability • Considerable flexibility with changes in geometry, without additional expenses • No storage or maintenance of patterns • Cost savings particularly for complex molds and batch sizes of 1 to several hundred pieces

Request for a quote

GLT BEARINGS GMBH

Germany

Fibre-reinforced compound sliding bearing in wound technology | Maintenance-free | Highly resilient COM-KU®/D-438 Wear rings are a self-lubricating and maintenance-free compound guide ring. It has good sliding properties and is suitable for high loads (also impact loads and with edge pressure). Good damping properties, very suitable for low sliding speeds, good chemical resistance, long service life. The use of this guide ring simplifies the design of the cylinder head. Easy mounting possible in closed and undercut installation spaces.

Request for a quote

SPIROL

Germany

SPIROL's Model HC Dual Pin Inserter is a lightweight, portable, horizontal Pin Inserter designed to install SPIROL Series 550 Cosmetic Coiled Pins into plastic hinges. The cylinder/driving head modules can be moved in and out with ease, and fixture changes are simple which enables quick conversion from one assembly to another. This machine quickly and effectively delivers the pins automatically to the installation site eliminating the need for the operator to touch them during the entire assembly operation. This machine dramatically increases production efficiency with minimal operator training and effort.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

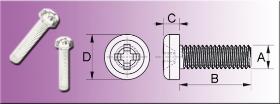

Material: PC Colour: transparent

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application Heavy cylinder heads of large diesel engines can be safely and easily clamped onto the extremely stable WV Cylinder Head Stand to perform maintenance and repair work. If required, the WV can be also used for storing a spare cylinder head. Features The cylinder head mounted on the WV Cylinder Head Stand can be rotated through 360° and locked in any position which is most suitable for the work to be performed. A removeable tray provided in the bottom frame collects any liquid from the cylinder head. Antivibration pads are provided at the bottom frame which are to be secured to the floor so that the stand cannot fall over when mounting and servicing the cylinder head.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The RCM is designed for refacing - the landing surface for the cylinder liner on the engine block, - the landing surface for the cylinder head on the cylinder liner - the landing surface for the cylinder liner on the cylinder head. Capacity Refacing diameter range 200 - 720mm Features The RCM is fitted with two motors providing a smooth cutting action. The speed of the motors is infinitely variable so that the cutting speed can be adapted to the diameter and material of the landing surface. A separate power supply unit is provided for ease of operation. A small hand-held remote control is supplied so that the operator can conveniently switch on and off the machine while watching the refacing operation. The remote control includes an emergency stop to stop the machine in case of emergency. The RCM is centered by a pilot tailored to the specific engine component to be serviced.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VD4HD-RC is designed for refacing • the landing surface for the cylinder liner on the engine block, • the landing surface for the cylinder head on the cylinder liner and • the landing surface for the cylinder liner on the cylinder head. Features Drive unit and gear head of the VD4HD-RC are identical with the drive unit and gear head of the VD4HD Valve Seat Refacing Machine. If you have already a VD4E machine and you want to use it with our new face turning heads, we can convert it into the new high performance VD4HD System. The three available face turning heads should be used according to our recommendation with the VD4HD drive unit and the related power supply type 4HD. We would be glad to advise you about our new VD4HD system and send you an offer for this. The D4/0° adapter head is bolted to the gear head in place of the valve seat refacing head. The VD4HD-RC is centered by a pilot assembly which is designed to fit to the engine component to be serviced.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application With the PVM1 assembly set, worn valve guides can be quickly and easily removed from the cylinder head and new valve guides inserted into the cylinder head. The assembly set is particularly suitable for motorcycle, car and commercial vehicle workshops. Features The air hammer can also be used to drive valve seat inserts out of the cylinder head. For this purpose a Hunger valve seat turning device is used to turn a groove into the valve seat ring. The seat ring is driven out of the cylinder head by means of a clamping head whose expandable clamping elements engage in the groove. Handling Insert the appropriate drift pin into the pneumatic hammer and insert the drift pin into the valve guide. Switch on the compressed air supply with the control lever provided on the pistol grip of the air hammer. The valve guide is driven out of or into the cylinder head by the rapid impact sequence. A soft protective ring placed on the drift pin protects the valve guide from damage.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

The new portable HUNGER universal refacing machine UDM4E is a versatile machine offering a choice of modular components for refacing valves and valve seats as well as counterboring seat ring pockets and resurfacing the sealing surfaces on cylinder heads, cylinder liners and engine blocks of large diesel and gas engines. Key features: - No abrasive dust. A fast clean cut, - Compact and handy design - Modular add-on components provide a flexible solution for multiple projects - Powered by SELV (Safety Extra Low Voltage) to avoid risk of electrical shock - Power supply with universal AC input - Fast set-up time - Easy to use - The economical solution for both field and workshop use »Roundness, concentricity and surface finish of the refaced faces are within manufacturers’ specifications or even better«

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VDS2 is designed to reface valve seats of the engines of trucks. heavy construction vehicles and small ships. Features The VDS2 refaces the valve seat in a lathe-type facing action. A gear head includes a feed mechanism for continous outward transverse motion of the single point turning tool when the VDS2 is rotated around a pilot inserted in the valve guide. The direction of the feed motion is defined by an exchangeable adapter head screwed to the gear head. A steady rest which is mounted on the cylinder head stabilizes the VDS2 below the crank handle. The steady rest eliminates runout when rotating the VDS2 around the pilot. As a result, the seat is refaced to concentricity with the valve guide under the correct seat angle.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VDS1A is designed to reface valve seats of the engines of motorcycles, cars and light commericial vehicles. Features The VDS1A refaces the valve seat in a lathe-type facing action. A gear head includes a feed mechanism for continous outward transverse motion of the single point turning tool when the VDS1a is rotated around a pilot inserted in the valve guide. The direction of the feed motion is defined by an exchangeable adapter head screwed to the gear head. A steady rest which is mounted on the cylinder head stabilizes the VDS1A below the crank handle. The steady rest eliminates runout when rotating the VDS1A around the pilot. As a result, the seat is refaced to concentricity with the valve guide under the correct seat angle.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Inspection of Surfaces 2D and 3D Regarding surface quality inspection for metal products such as cylinder head, gear tooth, it consumes a lot of time and human resources for the inspection. Since parts are inspected by bare eyes or slow speed inspection machines. With the inspection machine HE1000, inspection is much faster, more accurate and fully automated. In addition, there is a 3D laser sensor combined with our 2D inspection head to provide the most accurate result. This sensor is the first in the world to apply the Nobel Prize winning physics technology of optical frequency combs. It utilizes coaxial lasers and high precision range finders. There are some cases that our customers reduced over 90% of the inspection time. urthermore, if parts are inspected by humans, there might be different results by each person, because each of them has a different tendency and criterion.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The Hunger RDS is designed to precision machine the seat ring bores in cylinder heads to produce smooth and closely fitting contact surfaces for oversize seat inserts. Features The RDS is equipped for counterboring as well as for facing the bottom of seat ring bores in a lathe-type action with a single point carbide cutter. The RDS is aligned in centerline with the valve guide by means of a pilot which is locked in the valve guide. An universal steady stabilizes the RDS against lateral displacement. Pilots and steady furnished with Hunger valve seat refacing tool also suit for the corresponding RDS tool. The built in feed gear mechanism for automatic longitudinal and cross feed of the single point cutter eliminates the need for multiple cutter sets and other accessories. An adjustable stop for the tool slide permits quick selection of the proper sized bore diameter.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VD2 is designed to reface valve seats of the engines of trucks. heavy construction vehicles and small ships. Features The VD2 refaces the valve seat in a lathe-type facing action. The tool head includes two inclined slideways for refacing 30° and 45° valve seats. A single point turning tool is clamped to tool slide guided in the respective slideway. When the VD2 is rotated around the pilot by hand, the turning tool travels in a circle around the valve seat with continuous outward transverse feed motion under the correct seat angle. A steady rest which is mounted on the cylinder head stabilizes the VD2 below the crank handle. The steady rest eliminates runout when rotating the VD2 around the pilot. As a result, the seat is refaced to concentricity with the valve guide under the correct seat angle.

Request for a quoteResults for

Cylinder heads - Import exportNumber of results

16 ProductsCompany type

Category