- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cleaning

Results for

Cleaning - Import export

PNZ-PRODUKTE GMBH

Germany

Suitable for dilution of all solvent-based products. Brush Cleaner cleans and degreases tools, machines and dirty substrates.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for bio Brush Cleaner cleans and degreases tools, machines and dirty substrates.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for wooden and plastic surfaces. Furniture Refresher protects, cleans and preserves varnished furniture with a satin gloss, countertops, shelves, doors and tabletops. Rejuvenates the color and helps to cover gray seepage, scratches and mold stains.

Request for a quote

PEKU FOLIEN GMBH

Germany

Cleanroom bags and films - low-particle cleanroom bags and cleanroom films for research, pharmaceuticals, medicals Highest quality standards according to DIN EN ISO 14644, ISO 7, ISO 5 are fulfilled.

Request for a quote

APROVIS

Germany

What you can expect with an APROVIS ActiCo: - Careful gas purification - Reduction of emissions - Damage prevention - Higher operational reliability - An improved combustion process - An extended activated carbon service life

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Fully synthetic oil for use at permanently low temperatures in all areas of the food processing industry, for example in cold storage houses, shock freezers, etc. Chain lubrication at arctic temperatures Advantages and benefits NSF H1-registered MOSH/MOAH free Excellent low-temperature behaviour Good ageing and oxidation stability through optimal additives Cold and hot water resistant Resistant to water steam, as well as disinfectants and cleaning agents Long economic operating times

Request for a quote

MIROMATIC MASCHINENBAU GMBH

Germany

miromatic – Also produces and manufactures systems for cleaning and sterilising its own machines, as well as for integration into an existing process infrastructure. Innovative CIP concepts for different application areas Product safety at every point of the process Custom configurations tailored to your production process Automatic cleaning of the product conveyance lines Your added value through miromatic CIP systems: Low investment costs Rapid commissioning Short downtimes Correct cleaning results determine the production reliability

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for cleaning leached, waxed or oiled surfaces like sophisticated floors, cladding of walls and ceilings, doors, furniture, work tops and laminate, but also for varnished parquet and cork surfaces. Wood Floor Soap cleans and maintains indoor softwood and hardwood surfaces. This product is suitable for initial treatment.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for restoration and cleaning of grayed wood outdoors. The natural color of the wood becomes visible again with this special detergent. For long-term protection against graying and to preserve the natural color, apply a suitable pigmented product.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for basic cleaning of vinyl floors. Vinyl Intensive Cleaner cleans the floor prior to a refinish and removes old gloss finish, polymer layers, waxes, oil films and other contaminants.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for specially made for maintenance cleaning of any vinyl floors or surfaces.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for any water-resistant surfaces such as tiles, tiling, ceramics, glass, windows, metal pars, plastic surfaces, synthetic and genuine leather, lights and garden furniture. Universal Cleaner can also be used for flexible flooring made of PVC, CV, polyolefin, linoleum, rubber as well as natural and artificial stone.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for full care of any water-proof floors and coats, i.e. sealed parquet, cork, PVC, linoleum, laminate, natural and artificial stone floors as well as tiles and rubber floors. Floor Shine is suitable for both polishing initial treatment as well as continued maintenance when added to mopping water.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for basic cleaning of all floors like, parquet, plastic flooring, cork, PVC, linoleum, laminate, natural and artificial stone floors as well as tiles and rubber floors. Floor and Laminate Cleaner cleans waxed and oiled floors prior to a refinish and removes old gloss finish, polymer layers, waxes, oil films and other contaminants.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for intensive cleaning of WPC (Wood-Plastic Composites), as well as Resysta and synthetic rattan surfaces. The special cleaning agent restores the original color.

Request for a quote

PERO AG

Germany

In industrial parts cleaning, wet media are used in 70 to 90 % of all cleaning processes. Wet media include aqueous solutions – similar to detergents we use to wash our dishes or laundry – as well as nonaqueous solvents. For each cleaning task, project engineers must choose the best wet medium, taking into account ecological and economic considerations. Workpieces and parts are produced in finetuned production processes that often require the use of special consumables and process chemicals. Parts are generally made from specific materials, and their contamination after machining is determined by the processes they have undergone. When assessing the environmental impact of cleaning media, one sometimes comes to surprising conclusions. First of all, the energy input and use of resources must be assessed.

Request for a quote

PERO AG

Germany

The modular, preassembled PERO R2 units are available at short notice for your specific application Thanks to its unique design and optimised process technology, the R2 offers maximum throughput rates and excellent cleaning quality. At the same time, the unit is know for its energy efficiency. The performance of the R2 is primary determined by the size of the parts carrier and the cycle time per batch. As the R2 is available with chambers of various size, it is probably the most flexible cleaning unit in its class Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit 660 x 480 x 300 mm (std.) 1.000 x 480 x 300 (B chamber) 1.340 x 480 x 300 mm (D chamber) High flexibility Maximum throughput Unrivalled cleaning quality Available as 1 and 2bath unit with loading of the unit via Manual charging unit Automatic charging unit Hall trolley

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PERO AG

Germany

Bring your dirty parts to the PERO Centre of Competence. The cleaning experts of PERO will advise you in how these parts can best be cleaned. You can then perform a series of tests in order to identify the optimised cleaning process for your parts. Cleaning tests free of charge, using your own parts; including documentation Evaluation of cleanliness analyses Gaining new insights into own cleaning processes

Request for a quote

PERO AG

Germany

PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. In manufacturing plants, parts cleaning is one of the key activities along the production line. The productivity of a manufacturing plant is determined by the availability of the cleaning technology. At the PERO Centre of Competence, PERO specialists work together with operators to develop the cleaning method that best suits their needs.

Request for a quote

PERO AG

Germany

To develop a cleaning solution that meets the specifications, PERO engineers identify the best wet cleaning method and devise the sequence of the process steps as well as the process parameters. The effectiveness and efficiency of the chosen process is then verified by test runs performed at the PERO Centre of Competence.

Request for a quote

PERO AG

Germany

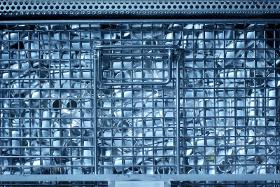

To achieve the required technical cleanliness, the parts must be correctly handled and placed in the cleaning unit. This is normally done by using special parts carriers that can withstand the cleaning conditions.

Request for a quote

PERO AG

Germany

After cleaning, parts are normally dried. Efficient drying keeps cleaning medium consumption low, and thus helps protect the environment. In addition, drying effectively prevents recontamination and corrosion. When drying tightly packed or porous parts, drying at atmospheric pressure might not be effective, so that drying under vacuum is the only option.

Request for a quote

PERO AG

Germany

Sound waves generated by an oscillator agitate the wet medium. This leads to cavitation bubbles that implode at a high frequency and result in hydraulic impacts. These impacts combined with microflows flush particles and pigments off the parts. The costs of ultrasonic cleaning are primarily determined by the processing time. Low ultrasonic frequencies remove coarse dirt, while high ultrasonic frequencies are used to eliminate fine dirt from parts.

Request for a quote

PERO AG

Germany

The parts are immersed in the wet medium. Dirt is dissolved from the surface by the heated wet medium. By moving the parts while immersed, cleaning is assisted by a mechanical effect. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quote

PERO AG

Germany

The parts are flooded by the wet medium kept in motion, so that even persistent dirt is removed.

Request for a quote

PERO AG

Germany

The wet medium is sprayed through nozzles onto the surfaces of the parts. Particles are removed from the parts by kinetic energy, and then washed away. The cleaning result is primarily determined by the position and shape of the nozzles, the spray pressure and the volume of media applied to the parts. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quote

PERO AG

Germany

The cleaning process must be designed to eliminate specific contaminants and particles from machined workpieces and parts in order to achieve the required technical cleanliness. For the wet cleaning of parts, the four parameters of the Sinner's Circle need to be combined and adjusted for optimised efficiency. PERO units offer efficient cleaning mechanics and reliable process control. According to the Sinner's Circle, the cleaning result is determined by four basic variables. By adjusting and combining these interrelated variables, it is possible to optimise any cleaning process. Good mechanical design of a cleaning unit optimises the mechanics of the process, which generally means that cleaning is completed in less time and with less resources.

Request for a quote

PERO AG

Germany

For all cleaning methods, operators must comply with the applicable statutory regulations at local, national and international level. The handling and the treatment of the cleaning media are two important aspects that must be taken into account when assessing cleaning tasks and suitable methods.

Request for a quote

PERO AG

Germany

The less space between the parts, the more difficult it is to remove particles and contaminants with a wet medium. The handling of the parts and the design of the parts carriers are therefore important aspects for optimised cleaning. Wet media are used in units with 1, 2, 3 or even more baths where the parts are cleaned and rinsed, and, if required, treated with preservation agents.

Request for a quoteResults for

Cleaning - Import exportNumber of results

49 ProductsCompany type