- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- injection

Results for

Injection - Import export

SCHMITTER HYDRAULIK GMBH

Germany

Category Diesel technology / Service parts for injection pipes / Union nuts for injection pipes Product number supplier 244004

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Category Diesel technology / Service parts for injection pipes / Union nuts for injection pipes Product number supplier 244002

Request for a quote

HEXPOL TPE GMBH

Germany

In the injection moulding process TPE pellets are fed into the machine through a hopper and then into a heated barrel. The heat from the barrel turns the material into a liquid resin which is then injected into a closed mould under high pressure. After allowing the molten polymer to cool, the finished part can be removed from the mould. Injection moulding is a high-volume, high tooling cost process, the advanced properties of our TPE compounds deliver short cycle times allowing parts to be produced at a rapid rate. The information below is intended as a general overview, settings may vary depending on the specific grade selected. Please CONTACT US for detailed processing information Settings Equipment Conventional injection moulding machine Compression set At least 2:1. Special screws with short sections and higher compression ratios (3:1 to 4:1) may be good at low screw speeds Shrinkage Between 1.0% and 2.5% depending on the grade, type of application and location of the gate. Moul

Request for a quote

HEXPOL TPE GMBH

Germany

Dryflex SE is our standard TPE range. It is extremely adaptable and can be used advantageously in many applications. The compounds are easy to process and are optimised for injection moulding. We have developed endless formulations to fulfil different properties and application requirements to optimise the finished component. Grades with improved compression set properties, high temperature resistance or more cost efficient values are an essential part of today’s wide product spectrum. Key Properties Unfilled, semi-filled & filled series 30 to 90 Shore A hardnesses Translucent, black, natural or coloured compounds are available Good adhesion to PP & PE High flexibility Easy processing via injection moulding Good mechanical properties Applications with food contact are possible Service temperature range from -50°C to 125°C (unstressed) Conforms to European directives 2002/95/EC (RoHS) and 2003/11/EC 100% recyclable Processing Dryflex SE TPE compounds can be processed using con

Request for a quote

GAPLAST GMBH

Germany

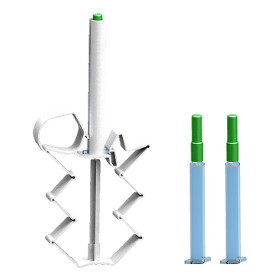

LIQUID Sub-cutaneous Use The prefilled syringe is mounted into the reusable activation device. After removal of the tip cap, the ModularInject is placed to the injection point. By activating the device, the skin is penetrated and the drug substance is injected. After the injection is finished, the syringe is discharged and can be disposed as usual. The activation device is ready for the following administration. ModularInject Monodose Injection Unique and smart solution to close the gap between manually applied prefilled syringes and complex auto-injectors. Single Use: Prefilled syringe with tip cap Multiple Use: One-piece activation device with an integrated plunger, automatic penetration, traveller and needle security functionality System Benefits (B2B) Applied/used either with a standard prefilled syringe in accordance to ISO 11040-4 or alternatively with an own developed packaging optimized prefilled syringe Free set combination of different dosages or different drugs...

Request for a quote

FRIEDENSTAB KUNSTSTOFFTECHNIK GMBH

Germany

With a modern machine park, we are able to produce injection molded parts up to approx. 400 grams. The materials used for this are e.g. PS, ABS, PP and PE, but also technical plastics. With a modern machine park, we are able to produce injection molded parts up to approx. 400 grams. The materials used for this are e.g. PS, ABS, PP and PE, but also technical plastics such as PA6, POM or IXEF are often used. Brief overview ARBURG injection molding machines Component weight: approx. 2 - 400 grams Closing forces: 50 - 220 tons Hybrid components (insert / outsert technology) Removal robots / vacuum gripping systems Automation around the injection molding process Central material handling system Material preparation Material drying

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Injection - Import exportNumber of results

6 ProductsCountries

Company type