- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial maintenance

Results for

Industrial maintenance - Import export

RIDZEWSKI GMBH

Germany

The automatic leakage tester used to control the tightness of CO2 inert gas packaging allows even the smallest leaks - even in the micro range - to be detected.The package is tested by simply placing it in the vacuum chamber. The automatic test cycle starts when the lid is closed. The unit generates a user-defined vacuum during this process. After the vacuum is reached, the sensor is set to the "virtual" zero point. If the CO2 concentration rises during the measuring time that now begins and was previously selected by the user, this indicates that the packaging is leaking. The measured increase of the CO2 content in ppm gives information about the size of the not tightly sealed area. The sensor demonstrably detects even the smallest leaks up to approx. 10 µm. (µm is a micrometre and corresponds to 0.001 millimetres)

Request for a quote

RIDZEWSKI GMBH

Germany

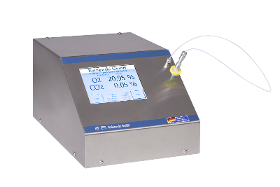

The EPC Spot is our measuring device for a random check of the gas levels of O2/CO2 in packaging or packaging machines. A sample is taken by a special needle. Due to the small amount of gas the analyser needs for the measurement, blister packs or ampoules can also be tested. As a user, you can enter several limit values for different products in the device. The result is then additionally visualised in red or green. All measurements are stored in the device and can be further processed in various ways. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

RIDZEWSKI GMBH

Germany

The EPC VM is our measuring device for monitoring O2/CO2 in packaging machines. In addition to continuous measurement of the gas atmosphere, spot measurement of individual packages is also possible. The functionality is the same as with our Zr-Ox EPC spot analyser. Once set, the analyser can also control the gassing of the machine. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels

Request for a quote

RIDZEWSKI GMBH

Germany

The EPC SMC is equipped with an integrated proportional valve. This allows the analyser to automatically regulate the gassing in a wide range of processes. All settings for the control can be configured on the unit or via external signals. This means that the customer is not required to control the process completely manually. This gives you the option of controlling the gassing at our analyser or at the plant. For some processes, a single adjustment is sufficient and the production runs fully automatically from then on. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

RIDZEWSKI GMBH

Germany

Our EPC 3GAS analyser is a more flexible variation of the basic model. The device changes the measurement automatically or externally controlled in order to monitor several processes simultaneously or consecutively. The change of the currently active measurement from process 1. to process 2. is done either by an external signal or in an adjustable time interval. Since our sensors can determine the oxygen concentration very quickly, time intervals of 30 seconds are realistically achievable. With desired concentrations of approx. 500 ppm, this is completely sufficient. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

RIDZEWSKI GMBH

Germany

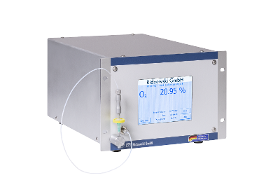

The Zr-Ox EPC is our standard model for continuous monitoring of residual oxygen. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels - Standardised 0/2-5/10 VDC or 00/04-20 mA analogue signal adjustable - 3 backups for storing different unit functions and settings - Display of all alarms and errors

Request for a quote

GEDA GMBH

Germany

Wherever heavy loads have to be transported to great heights, the new GEDA BL 2000 P ensures the required efficiency in the industry. With a load capacity of 2000 kg or 23 persons and a max. lifting speed of 40 m/min, this permanent passenger and material hoist is the new powerhouse from GEDA. The fixed platform size of 3.20 x 1.45 x 2.10 m also allows transport of bulky goods up to a height of 250 m. For added comfort and operating convenience, the hoist is equipped with comprehensive state-of-the-art control variants. The GEDA BL 2000 P is perfectly tailored to the requirements in rough industrial environments. Maintenance and repair work can be conducted efficiently with the permanent passenger and material hoist.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

High absorbent properties of a natural fiber with the cleanliness, strength, and durability of synthetic wipers; woodpulp added to polyester foundation long fibers providing excellent absorbency minimal extractable and ionic contaminants low static wipe meets the requirements for ISO Class 7 and FEDSTD209/D Class 10,000

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

knitted with carbon fiber recommended for ESDsensitive applications and cleanroom environment where particles is a concern complys with the ISO requirements of Class 4 and FEDSTD209/D Class 10

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

made of 100% Nonwoven PP material, with continuous filament 80 g/m² economic low lint wipe high water absorbency rate, lowlint and soft texture good water and oil absorbency suitable for cleaning of e.g. PCB solder paste, tools, machines, etc.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

made of microthin fibers with highest degree of cleanliness superior moisture and oil absorbency The unique construction of fibers absorbs up to 50% more compared to ordinary polyester wipers. nonabrasive complys with ISO requirements of Class 4 and FEDSTD209/D Class 10

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

100% polyester (75D / 72F) can be used under class 1.000 up to class 10.000 wipe is washable, with negligible deterioration in its performance Soft and nonabrasive on surfaces; good absorbency rate low particulates and ionic contents

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

100% polyester; double knitted to provide efficient cleaning of surfaces during maintenance of cleanroom under class 1000 to class 100,000. good absorbency rate multipurpose reusable wipe; washable wide range of application for cleaning specially cleanroom equipment like computers, electronic equipment, laboratory apparatus, tables and chairs, etc.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Formstable biaxially expanded ePTFE sheets or die cutted gaskets Characteristics Excellent adaption High blow-out resistance No cold flow Chemically inert Technical parameters pH 0 - 14 Temperature: t = -200 … +280 °C Pressure: p = Vacuum … 200 bar Density: 0,95 g/cm 3 (D11 - 0,7 g/cm 3) Minimum Surface pressure: VU (40 bar; 0,01) = 26 Mpa Maximum Surface Pressure: VO = 150 Mpa Minimum surface pressure in operation: BU < 5 Mpa Cold upset compression value: KSW = 40 % Remaining Thickness after compression approx. 15 % higher than values of D11. Main application Flanges Vessels Lids Joints Narrow flanges Bigger uneveness Tension sensitive components (e.g. sight glasses) Suitable for Chemical industry Food industry Maintenance Approvals DIN 28090-2 TA Luft 1,5 · 10 -8 mbar · l/(s·m) @ 250 °C FDA conformity EG 1935:2004 EU 10/2011 Form of delivery Sheet dimension: 1,000 x 1,100 mm and 1,500 x 1,500 mm Sheet gaskets thicknesses: 0.5 / 1.0 / 1.5 / 2.0 / 3.0 / 4.0 / 5.0...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Carbonized synthetic fiber with PTFE impregnation and run in lubricant Practical useful application data: max. temperature: +140 °C Characteristics Good flexibility Rot proof Form stable packing Good value for the money Recommended surface hardness HRC50 Operating range Pressure [p max]: 15 bar, Velocity [v max]: 15 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -50… +200 °C pH: 3 - 12 Density: 1.30 g/cm³ Practical useful application data: max. temperature: +140 °C Main application Centrifugal pumps Mixer Kneader Agitators Refiner Autoclave Gate valves Filter Suitable for Pulp and paper industry Sugar industry Waste water technology General maintenance Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special measurements. 04 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on 5 kg spool Special length, pre-cut or die formed rings on request. 1 kg...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Braid of ePTFE Fiber with Incorporated Graphite and Silicone Run-In Lubricants Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Characteristics Good heat conductivity Extended lifetime Easy installation and safe handling No ageing process Resistant against Sewage, Boiler Feed Water, Acids, Alkaline solutions, Oil and Grease Cost effective ePTFE/Graphite Packing Recommended shaft surface hardness: HRC 35 Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 250 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -100… +280 °C pH: 0 - 14 Density: 1.50 g/cm³ Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Main application Centrifugal pumps Mixer Kneader Agitators Autoclave Refiner Vacuum pumps Suitable for Chemical industry Power plant technology Pulp and paper industry Universal use Installation and maintenance...

Request for a quoteResults for

Industrial maintenance - Import exportNumber of results

20 ProductsCompany type