- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding wheel

Results for

Grinding wheel - Import export

QUELLTECH GMBH

Germany

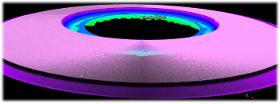

Particular Challenge: For the assessment of rotating parts, numerous parameters have to be taken into consideration: Concentricity, radial run-out and axial run-out (i.e. wobble); furthermore thickness, diameter, planarity and the absence of surface defects had to be examined. The solution developed by QuellTech consists in a configuration of three Q6 Laser Laser Scanners.Each of the lateral surfaces is assigned to its own scanner. In order to enable the thickness precisely to be determined, both laser lines are mutually oriented in opposite direction. The third scanner inspects the outer circumference of the wheel, this way measuring diameter and radial run-out. All of these scanners are subject to encoder signals supplied by the rotary axis and synchronously triggered, so possible defects on the wheel can precisely be localized. The measurement takes place at a resolution of ca. 30 µm, and a cloud comprising several millions of points are obtained.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The SG 175 support grinder is designed for grinding the conical seating surface of valves of medium speed diesel engines on a standard lathe. Handling The support grinder is clamped in the toolpost located on the top slide of the lathe. The grinding angle corresponding to the required valve seat angle is adjusted by turning the top slide of the lathe to an angular position which corresponds to the valve seat angle and which is defined by the template supplied with the grinder. The valve stem is clamped in the chuck of the lathe and the valve face is ground by feeding the grinding wheel into the rotating valve face. Features The precision grinding spindle is permanetly sealed and lubricated for lifetime accuracy. The wheel guarding system is designed to the prevailing safety regulations. The cone-shaped head of the template is provided with a bore receiving the dressing diamond so that the grinding wheel can be properly dressed after adjustment of the grinding angle.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure with integrated slideway for wheelhead. The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled coolant tank which can be drawn out for ease of cleaning. Workhead and Steady Rest Both the workhead and the steady rest are adjustable along the swivel plate to clamp each valve on that part of the valve stem which normally travels in the valve guide. The combination of collet chucking and the unique Hunger steadying provides double support of long valves to ensure the ultimate in valve refacing accuracy. Automated Oscillation An oscillating equipment for automated power traverse of valve face across the grinding wheel is available as an option to ensure efficient stock removal and superior finish. The stroke of oscillation is infinitely adjustable.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure for vibration-free performance. Adjustable slideways for wheelhead infeed and workhead traverse. Wheelhead Box type monobloc noted for its excellent vibration dampening characteristics. The precision motor grinding spindle is permanently sealed and lubricated. Workhead Located on a swivel plate which can be set to the required angular position by means of a wide-spaced scale. Collets for perfect valve alignment. Dressing Attachment The dressing attachment is permanently mounted on the worktable for rapid wheel dressing. Wet Grinding Coolant is delivered by an industrial type flood pump. The baffled coolant tank is easily removed from the machine base for cleaning. Electrical System Individual grinding spindle motor, work spindle motor and coolant pump motor all controlled by switches grouped in front of the wheelhead for ease of operation.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Selfcentering Steady (Option) Selfcentering steady rests are available to fit on the swivel plate slideway for additional support of long stem valves. Both the workhead and the stready rest are adjustable along the swivel plate to clamp each valve on that part of the valve stem which normally travels in the valve guide. The combination of collet chucking and the unique Hunger steadying provides double support of long valves to ensure the ultimate in valve refacing accuracy. Oscillating Equipment (Option) An oscillating equipment for automated power traverse of valve face across the grinding wheel is available to ensure efficient stock removal and superior finish. The stroke of oscillation is infinitely adjustable. Automated Infeed (Option) Power infeed is available for automatic grinding according to a preselected program. The feed rate, the total infeed and the sparkout time can be easily selected.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAPP NILES GMBH & CO. KG

Germany

Beside the non-dressable CBN grinding tools, dressable grinding tools of leading manufacturers can be used on our machines, too. Vitrified bond aluminium oxide tools are dominant. Sintered aluminium oxide is preferred as the grinding tool for grinding of steel due to its resilience and grinding capability. Gray cast-iron can also be processed with normal aluminium oxide. The profiling of the grinding tools takes place via a machine-integrated CNC dressing unit. A diamond-plated, rotating dressing tool profiles the wheel in accordance with the respective gear parameters. The grinding tool is conditioned specifically for rough or finish grinding by selecting respective technological dressing parameters. Form consistency and cutting capacity of the grinding wheel is assured by repeated dressings, dependent on pre-defined stock removal rates. The automatic balancing produces smoother turning for larger grinding tools, and consequently, high gear quality. dressable CBN tools Single-layere

Request for a quoteResults for

Grinding wheel - Import exportNumber of results

7 ProductsCountries

Company type