- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- forcing

Results for

Forcing - Import export

KAUP GMBH & CO KG

Germany

The ‚Smart Load Control‘ (SLC) system regulates, as the only one on the market, the clamping force on appliance-/carton clamps exclusively load dependent and not load pattern dependent. The weight is decisive for the flexible definition of the clamping force - not the dimensions of the load. The aim of the system is to ensure that only as much clamping force as really necessary acts on the load.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

The peel force is a critical parameter for every user of Tape & Reel. If the peel force is too low, the cover tape will not stick on the carrier tape properly and the components may fall out of the pockets. A too high peel force will cause costly down times at the pick & place machines. The KT 5000 peel force tester from KTECH is the ideal tool to measure the peel force on your production floor. For measuring, a strip of the carrier tape is loaded into the KT 5000 and the cover tape is attached to the sensor. The constant movement of the carrier tape is done with a sprocket wheel. The movement speed is controlled with an encoder. The design of the KT 5000 guarantees the same peel angle and the same peel point during the whole measurement. Before each run, the KT 5000 is doing a selfcalibration of the sensor. The measured values are transferred to a PC via a serial RS232 interface. A green bar on the screen shows a good result, if the measurement is out of limit, the bar is red.

Request for a quote

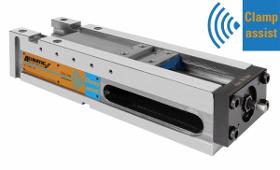

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Compatibility: The mobile wireless receiver can be coupled with Vices of ALLMATIC Clamp assist Serie: TITAN 2 K/M/L TITAN 2-160 Scope of application: -Acquisition of the current tensions in the fully encapsulated high pressure spindle by means of an integrated, electronic measuring system and transfer to the mobile receiving unit -Independent from the jaws, the measurement system is integrated in the spindle -Clamping force is constantly monitored during its actual tension condition -Storing of the clamping forces can be called up at any time through the electronics integrated in the spindle -Power values are transmitted via radio to the mobile receiving unit (MWR) (2. 4 GHz) -MWR simultaneously and digitally displays the clamping force for up to 4 spindles in kN -The clamping force (reference power) default, set by the user, is indicated by a led at the MWR upon reaching the 90% mark -The last 200 stored clamping operations can be transferred in CSV format

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal and vertical use - therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, grip clamping and low tension clapping possible -Titanium 2 K - ideal for use on 5-axis machining centers -Clamping of raw, thermal and saw cut parts by penetrating hardened and interchangeable grip elements into the work piece -The support jaws safely and cost effectively allow raw part, different types of materials and complex geometries to be handled Product features: -To monitor and optimize milling processes -Safety for people and machines -High flexibility - the modular clamping system combines almost all possibilities of our tried and tested models -Titanium 2 M - finely polished sides so that all sides can be used -Titanium 2 K and M can be vertically used Force translated high-pressure spindle -Increased power stroke for safe clamping of raw parts -Loss of 8 mm clamping edge in low tension, 3 mm with GRIPP

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal & vertical use - therefore suitable for vertical & horizontal CNC milling machines -Conventional clamping, grip clamping and low tension clapping possible -Titanium 2 K - ideal for use on 5-axis machining centers -Clamping of raw, thermal & saw cut parts by penetrating hardened & interchangeable grip elements into the work piece -The support jaws safely & cost effectively allow raw part, different types of materials & complex geometries to be handled Product features: -To monitor & optimize milling processes -Safety for people & machines -High flexibility - the modular clamping system combines almost all possibilities of our tried & tested models -Titanium 2 M - finely polished sides so that all sides can be used -Titanium 2 K and M can be vertically used -Force translated high-pressure spindle. -Increased power stroke for safe clamping of raw parts -Loss of 8 mm clamping edge in low tension, 3 mm with GRIPP

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JAKOB ANTRIEBSTECHNIK GMBH

Germany

Hydraulic load cells of the HMD series are robust measuring instruments that gauge axial compressive forces with median accuracy. The force is transferred by pressure pistons analogously and via the hydraulic fluid to a manometer with a kN-indicator scale. The measuring system is autarkic so there is no need for external or supplemental power. Therefore, static and dynamic forces can be detected in numerous applications of the entire spectrum of mechanical engineering in an easy and economical way. Construction features: • autarkic system - no external power • heat treated steel - corrosion resistant • multi piston system - compensation of erroneous angle

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• high clamping forces - low tightening torques • with bottomed thread - thread protected • centered operation • compact design - up to 200° C (optional up to 400°C)

Request for a quoteResults for

Forcing - Import exportNumber of results

8 ProductsCountries

Company type