- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filter screens

Results for

Filter screens - Import export

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers you customised solutions for water treatment using mineral wool wash water plants. Benefit from our extensive experience in the field of insulating materials. Functions of mineral wool wash water plants: Planning, design, construction, assembly and commissioning of systems for the collection and treatment of waste water from the production process Multi-stage filtration and purification of the water using settling tanks with agitators, screening machines, drum filters and hydrocyclones

Request for a quote

PERO AG

Germany

Wet media differ greatly as regards safe handling, service life and cost of treatment. Surface tension Degreasing properties Cleaning properties Drying properties Residues Filtration properties Bag filter Cartridge filter Distillation Screen basket filter Settling chamber Micro/Ultrafiltration Filling Stabilising Distilling ReFilling Stock bath Bath treatment/Titration Bath change Disposal

Request for a quote

RIDZEWSKI GMBH

Germany

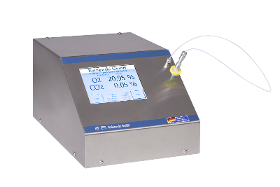

The EPC Spot is our measuring device for a random check of the gas levels of O2/CO2 in packaging or packaging machines. A sample is taken by a special needle. Due to the small amount of gas the analyser needs for the measurement, blister packs or ampoules can also be tested. As a user, you can enter several limit values for different products in the device. The result is then additionally visualised in red or green. All measurements are stored in the device and can be further processed in various ways. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

RIDZEWSKI GMBH

Germany

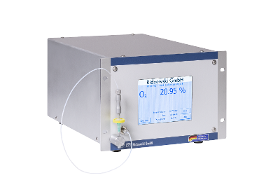

The EPC VM is our measuring device for monitoring O2/CO2 in packaging machines. In addition to continuous measurement of the gas atmosphere, spot measurement of individual packages is also possible. The functionality is the same as with our Zr-Ox EPC spot analyser. Once set, the analyser can also control the gassing of the machine. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels

Request for a quote

RIDZEWSKI GMBH

Germany

The EPC SMC is equipped with an integrated proportional valve. This allows the analyser to automatically regulate the gassing in a wide range of processes. All settings for the control can be configured on the unit or via external signals. This means that the customer is not required to control the process completely manually. This gives you the option of controlling the gassing at our analyser or at the plant. For some processes, a single adjustment is sufficient and the production runs fully automatically from then on. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RIDZEWSKI GMBH

Germany

The Zr-Ox EPC is our standard model for continuous monitoring of residual oxygen. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels - Standardised 0/2-5/10 VDC or 00/04-20 mA analogue signal adjustable - 3 backups for storing different unit functions and settings - Display of all alarms and errors

Request for a quoteResults for

Filter screens - Import exportNumber of results

7 ProductsCountries

Company type