- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drilling

Results for

Drilling - Import export

ROSE PLASTIC AG

Germany

High-quality plastic cassettes in modern design. Ideal for all kinds of drill bit sets, precision tools, shank tools, special tool sets and spare parts Modular concept – cassettes can be combined with individual foam inserts or vacuum formed inserts Intergral secure locking mechanism to prevent unintended opening on impact Adjustable and flexible length stop for tools

Request for a quote

ROSE PLASTIC AG

Germany

Plastic drill cassettes for drill bit sets (HSS drill sets DIN 338, machine tap sets DIN 371/376 etc.) Four parts: cover, base, insert and safety pin Sturdy and modern design with ergonomic body design Clear cover allows for product visibility

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and suited for milling and drilling applications.

Request for a quote

SPIROL

Germany

SPIROL's Model DP self-contained vertical drilling and pinning machine is ideally suited for moderate to high production applications that require accurate drilling and pinning of assemblies. The concept of drilling and pinning with one system eliminates tight tolerance and precision drilling of individual components to ensure proper alignment of holes for assembly. The Model DP Drilling and Pinning Machine consists of an automatic high-precision drilling unit, a SPIROL Model CR Heavy Duty Pin Insertion Machine and a precision air-powered linear slide unit to move the assembly between the drill unit and installation station. The Model DP Drilling and Pinning Machine can drill holes ranging in diameter from 0.8mm-6mm (.031”-.250”) and is capable of insertion forces up to 8 kN (1,800 lbs).

Request for a quote

ROSE PLASTIC AG

Germany

Ergonomically optimized plastic assortment box with removable inserts. Ideal for drills, screws and small parts High transparency lid offers optimum visibility to contents User-friendly, easy grasp features on both sides 90° swiveling, retractable handle; additional safety lock prevents accidental opening

Request for a quote

ROSE PLASTIC AG

Germany

Packaging boxes with center spigot for spade drill inserts (series Y, Z, 0-8) Optimum fit through center post Secure press closure and hinged lid Durable and reusable

Request for a quote

SPIROL

Germany

DEWALT’s lead design engineer for drills was tasked with designing a high power right angle drill that is lightweight, compact, and portable. The goal with the design was to maximize performance while minimizing the size of the tool. The design would incorporate a mechanical clutch built to limit maximum torque output to 70 ft-lbs. Absent the clutch, with the huge gear reduction of 75:1, the drill would be capable of producing a lock rotor torque at the spindle of 175 ft-lbs, transmitted directly to the operator of the tool. It was determined early on that the clutching thrust required in the space available could only be achieved by a Disc Spring design. Compared to conventional coil springs, Disc Springs offer a higher load capacity in less space. Additionally, longevity and reliability is a high measure of quality for professional tools used on a daily basis. The life and performance warranty of the tool was reliant on the Disc Spring design. Visit SPIROL.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Profiles and sealing systems often require ventilation holes or mounting holes. Drilling equipment from Metzner carries out these tasks. We provide the following solutions adapted to your specific requirements: - In-line as an eccentric drilling station for regular drilling at equal distances - In-line as travelling drilling station for drilling at the same or variable distance - In-line as "drilling beam", which carries out all drillings for an entire sealing profile with variable distances in one operation - Off-line for drilling in combination with final trimming The machine is equipped with drilling spindles with very high speeds of up to 60,000 revolutions per minute. An exact drill hole is thus achieved in a short cycle time. The geometry of the drills ensures that the waste falls to the outside.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

With automatic continuous punching machines, machine and tool merge into a high-performance system with high output and remarkable flexibility. Whether sealing profiles for the automotive industry, applications for furniture, or household appliances – complex trimming is often required here. Thanks to the Metzner automatic throughfeed punching machines, processing operations such as contour cutting, drilling and milling can be integrated into a throughfeed system. All these machines store all machining parameters and machine settings in a machining recipe. When starting production, an integrated barcode scanner activates all presettings on the basis of the working papers and simultaneously reports the correct tool and material on the machine display. The barcode also contains the required quantities and lengths. Thanks to well thought-out quick-change systems, tools and materials are generally changed within no more than 30 seconds, minimizing downtimes.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Digital readouts from HEIDENHAIN are used in a wide variety of applications. They are deployed on machine tools, infeed axes on saws and presses, measuring and inspection equipment, dividing apparatuses, setting tools, production inspection measuring stations, and more. To meet such demands, these digital readouts can also be used in combination with numerous encoders from HEIDENHAIN. Digital readouts with multiple axes are primarily used on manually operated machine tools, where their practical cycles provide optimal support to the operator during milling, drilling, or turning. By instantly displaying the position in an easy-to-read manner, digital readouts enable a significant increase in productivity.

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

When drilling, it is vital to ensure than concentricity is < 0.02 mm. The fundamental problem when drilling: if the cutting forces are high, the feed rate must be reduced. The same factors apply when step-drilling.

Request for a quote

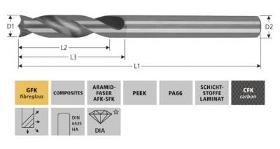

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide high-performance drill: with double flute, right-hand cutting, also available with coating

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide pyramid end mill: burr style with drill bit, right-hand cutting, shank without clamping surface DIN 6535-HA, suitable for fibreglass-reinforced plastics and foams, also available with diamond-coating (price on request)

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide high-performance drill: right-hand cutting, multidirectional, 90° point angle, prevents delamination, with diamond coating

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

solid carbide bevelling end mill: with double flute, right-hand cutting, with drill bit, side and bottom cut facility, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

carbide twist drill: with double flute, with centering tip, with pre-cutter, right or left hand rotation, suitable for all types of wood and MDF boards

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Drilling - Import exportNumber of results

17 ProductsCompany type