- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dischargers

Results for

Dischargers - Import export

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XL drum emptying system offers a modern way of emptying containers. The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - Bridge frame can be driven underneath with drums on pallets - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quote

MAHLO GMBH & CO. KG

Germany

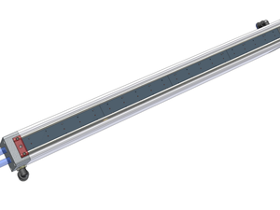

Ionisation of the air The Antistat AMW ioniser for trouble-free processing of synthetic materials and of textiles with high charge separation. By ionising the ambient air, the electrostatic charge is diverted from the product sheet. Antistat AMW can be used at high or low speeds.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

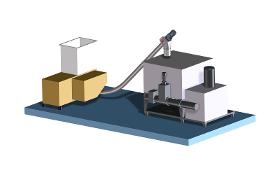

Based on a individual needs assessment we tailor-make briquetting solutions including peripheral devices. RUF lifting and tilting devices optimize and automatize the flow of bulk materials. RUF can consider any individual customer needs.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

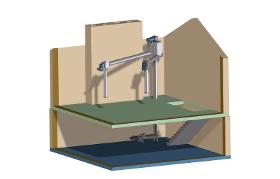

OKTOMAT® ECO is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The ECO series is the basic model of the OKTOMAT® emptying stations and is ideally suited for the majority of applications dealing with free-flowing to poorly flowable materials. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable. Due to its pedestal form, the ECO is particularly space-saving in width, the height is individually adjustable.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

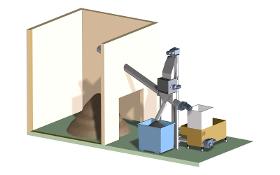

OKTOMAT® SOS is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its pedestal form, the OKTOMAT® SOS is particularly space-saving in width, the height is individually adjustable. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® SOS is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its pedestal form, the OKTOMAT® SOS is particularly space-saving in width, the height is individually adjustable. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quote

STEINER GMBH & CO. KG

Germany

For stationary hackers, we offer flexible and rigid discharging systems. With both systems we assume the material directly in the hacker and convey it to the desired discharge point. The transport takes place without any pressure. Due to our compact design you do not need ground indentations. Depending on the intended use, our rigid or flexible spirals will be fitted in. These systems could be combined with modules like magnetic separators or interim outlets.

Request for a quote

STEINER GMBH & CO. KG

Germany

For stationary hackers, we offer flexible and rigid discharging systems. With both systems we assume the material directly in the hacker and convey it to the desired discharge point. The transport takes place without any pressure. Due to our compact design you do not need ground indentations. Depending on the intended use, our rigid or flexible spirals will be fitted in. These systems could be combined with modules like magnetic separators or interim outlets.

Request for a quote

STEINER GMBH & CO. KG

Germany

For stationary hackers, we offer flexible and rigid discharging systems. With both systems we assume the material directly in the hacker and convey it to the desired discharge point. The transport takes place without any pressure. Due to our compact design you do not need ground indentations. Depending on the intended use, our rigid or flexible spirals will be fitted in. These systems could be combined with modules like magnetic separators or interim outlets.

Request for a quote

STEINER GMBH & CO. KG

Germany

For stationary hackers, we offer flexible and rigid discharging systems. With both systems we assume the material directly in the hacker and convey it to the desired discharge point. The transport takes place without any pressure. Due to our compact design you do not need ground indentations. Depending on the intended use, our rigid or flexible spirals will be fitted in. These systems could be combined with modules like magnetic separators or interim outlets.

Request for a quote

STEINER GMBH & CO. KG

Germany

For stationary hackers, we offer flexible and rigid discharging systems. With both systems we assume the material directly in the hacker and convey it to the desired discharge point. The transport takes place without any pressure. Due to our compact design you do not need ground indentations. Depending on the intended use, our rigid or flexible spirals will be fitted in. These systems could be combined with modules like magnetic separators or interim outlets.

Request for a quote

STEINER GMBH & CO. KG

Germany

For stationary hackers, we offer flexible and rigid discharging systems. With both systems we assume the material directly in the hacker and convey it to the desired discharge point. The transport takes place without any pressure. Due to our compact design you do not need ground indentations. Depending on the intended use, our rigid or flexible spirals will be fitted in. These systems could be combined with modules like magnetic separators or interim outlets.

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

STEINER GMBH & CO. KG

Germany

Impurities of your transported goods are often problematic and can be also guilty of disorders. They may even cause damage. But do not desperate! Our tried and tested magnetic separators will help you. These magnetic separators take care to filter out foreign substances. Simply and reliably.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quoteResults for

Dischargers - Import exportNumber of results

16 ProductsCompany type