- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutters

Results for

Cutters - Import export

ROSE PLASTIC AG

Germany

Plastic cases sturdily designed for all-around protection of high-quality milling cutter heads Extremely strong blown double-wall case Secure center fixing screw offers high protection of cutter edge Centering points on base and cover for secure stacking

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The powerful "universal cutting machine" with superior pulling and cutting strength. The contact pressure between the conveyor belts is pneumatically controlled and opens and closes automatically when the cover is opened and closed. Ideal for solid and dimensionally stable materials. Metzner also offers the Variocut in three “Red – Green – Blue" equipment lines. Each equipment variant is based on the same basic model with the same high-quality mechanical components. The individual models differ in speed, control and the interfaces for peripherals.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The specially developed production line can unwind, label, roughen, cut to length, strip, wind, bind and automatically deposit the cable wires. The material to be processed is unwound by a motorised unwinder and fed to a thermal transfer printer via a straightener. The latter prints the cable with two QR codes and a serial number. This ensures that each cable can be identified throughout the entire processing and manufacturing process and assigned to the stations which have already passed through. This traceability offers great advantages – for example in the diagnosis of faults. The cable then passes through a roughening station, which lightly roughens the material surface so that the connector overmoulding adheres better later on. An AM 3550 from Metzner Maschinenbau cuts to length and strips the cable, which is then transported to the winding station and onwards by a gripper to the binding machine. The latter winds the cable to form a cable ring.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Electrical cabinets contain the electrical and electronic components of a process engineering system, a machine tool, or production equipment that is not directly located in the machine. They are manufactured by special switch cabinet builders or by the machine manufacturers themselves. To save costs, there are automation solutions that are not only worthwhile for large production series, but are also suitable for the more efficient and economical production of individual and small series. Metzner offers a unique and comprehensive system solution to reduce your expenses in switchgear construction. Depending on your requirements, different stripping and crimping machines are available, which differ in terms of design, performance and degree of automation. METZNER TRIATHLON SERIES - for precise cutting to length and one- or two-sided stripping - for crimping the ferrules (single- and double-sided) - for individual labelling of strands with different printing method

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The Metzner AM 5000 range includes the flagship models for precise processing of thick cables up to 240 mm² section and 35 mm diameter. Even the basic specification models, with their high torque and powerful three-stage step motors offer the highest level of cutting and haul-off power. All models are equipped with as standard with the Metzner double-knife system that enables very varied and multi-stage processes to be performed. Moreover, with convincing operator-friendliness and long service life. Metzner AM 5000 models are also suited to processing thinner braided cables from 1.5 mm² The stripping full haul-off 1side/2nd side amount to 270-450 mm and 90-270 mm, for partial haul-off 450 mm and 270 mm. For interuption-free automatic production, a number of sensors monitor the material feeding If a material blockage occurs, the production stops automatically and the operator is informed about the cause of the fault.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The cable processing machines in the AM 3800 range are characterised by their outstanding cutting and haul-off power and their modular, robust and long-life construction for continuous use in industrial applications. These machines outstandingly combine power and versatility. Equipped with cutting power for cables up to 70 mm sectionand 20 mm diameter, they are the ideal solution for an unusually wide spectrum of applications. Depending o the processing demands, numerous knife contours and technologies are available: the patented double-knife system allows different processes to be performed in a single working pass. The circumferential rotary cut offers an exact cutting round cables with very thin or tough insulation outer cover.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Plastic-coated steel cablestrands are cut to length using a special shear cut module and then stripped with the cutting module of the AM3500 without the wires "jumping open".Bare steel cable wires are transported by the modified AM 3500 directly to the special cutting machine, which is coupled between the AM 3500 and the material stacker and which cuts the material to length by a thermal process. Due to the special electric welding process used here, the individual wires do not twist up during cutting, and a smooth rope start and a smooth rope end without thickening are produced. Long steel cable wires/strands are placed in a tray after processing, while short pieces of material fall down a chute into a collecting container. With the high-performance solution developed by Metzner, the customer can process different types of material in different processes. Further advantages of the machinery are high precision, high quality, an increase in productivity and lower personnel costs.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed a fully automatic processing machine with outstanding cutting quality and great length accuracy for steel cable wires of up to 20 mm diameter. The steel cable wires are fed by a motorised feeding device in combination with a contact-free loop control. Then, program-controlled and positionally accurate marking tapes are applied to the steel cable – with a cycle time of less than two seconds. In addition, a wax printer marks all the fastening and processing points that will be required for subsequent processing. This labelling method is carried out in a continuous process. The cut is then made using a special cutting process. Precise length accuracy is achieved by a special laser measuring system. A material stacker with a storage area of up to 12 metres ensures that the steel cable wires are deposited in an orderly manner. All cut steel rope can be stored and sorted according to length to allow it to be removed at a later point.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

This special Metzner development is able to process cable wires with a diameter of up to 28 mm. The cycle time for this is 2000 mm / 35 seconds. The processing steps include long slitting, sawing, circumferential cutting, stripping, brushing and depositing. An integrated ink jet printer labels the cable wires with information or markings. As the heart of the processing method, Metzner uses a newly developed stripping head that combines a rotary cut with a powerful clamping and simultaneous rotation of the material. This enables a high-precision, multi-stage radial cut through the various layers of material. Microscopic quality inspection confirms that the processing is flawless with no scratches, pressure or abrasion marks. In addition to the high machining quality, the machinery also offers special precision: both the overall length and the machining position are maintained with an accuracy of 0.2 mm. The machine can process cable wires with diameters up to 28 mm.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

For Fast and Economical Instant Manufacturing of Sheet Gaskets Characteristics Fast and flexible solution for a whole range of applications Easy and safe operation Round shapes cutting from 30 up to 1000 mm Suitable for various sheet thicknesses up to 9 mm Also small sized sheet pieces are processable Spare parts on request Version W5FDKS300 simple solution for easy and infrequent use for gaskets with a max outer diameter of 300 mm.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Simple Stuffing Box Packing Cutter for soft and medium-hard packing types. For 45° skive cut and 75° butt cut. Characteristics Quick change of cutting angle due to adjustable support. Easy handling due to precise angle cutting aligned to marks on the packing. Replacement blades available

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Compact and wear resistant tool made of aluminium. Advantages Packing cut without necessary length calculation (an adder-factor x - is already included) Time saving Repeatable results No waste Suitable as well for Trapez-Pack Technical data For shaft diameter up to 80 mm with W5PS-SK and 110 mm with W5PS-BU With extension W5PS-V-SK to 200 mm and W5PS-V-BU to 250 mm shaft diameter Scale: in inches and mm Packing sizes: from 3 to 25 mm Spare parts available Variants 45° skive cut type W5PS-SK 75° Butt cut type W5PS-BU Accessories Extension W5PS-V-SK Extension W5PS-V-BU Spare knife

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

Adjustable Handles: - Patent-pending adjustable handles for greater operator comfort. - Adjustment allows operator to be closer to cutting side for easier alignment and straighter cuts - Handle can be folded for transportation Depth Indicator: -Cut depth indicator shows both millimeters and inches IntelliSeal: -Patent-pending fully enclosed cutting shaft that is maintenance-free for at least 250 hours, eliminating the need for daily bearing lubrication Large water tank: -Large water tank made of impact-resistant plastic equipped with quick-connect coupling for water line connection on top of cut-off wheel guard -No tools required for disassembly

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

Technical information: Disc milling cutters are ideally suited for machining long, deep grooves quickly and cost-effectively. It is also possible to incorporate disc milling cutters into a set and cut several grooves at the same time. Tool systems: The Zinner RC disc milling cutter can efficiently machine deep grooves with depths from 1.6 mm to 8.0 mm. If necessary, they can also be used for parting. The cutting tips of the RC disc milling cutter and be customised to meet almost every customer requirement. The SPM 03 disc milling cutter can cover a range of cutting widths from 8.0 -20 mm; this variant is equipped with left and right cutting inserts.

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

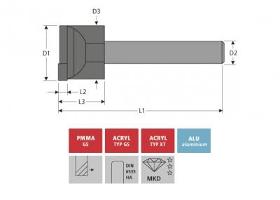

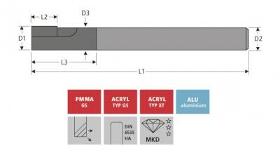

MCD face-milling cutter: with single flute, right-hand cutting, for high gloss mirror finish, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

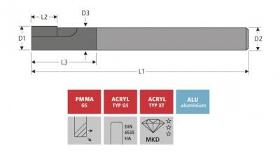

MCD circumference-milling cutter: with single flute, right-hand cutting, circumference-milling, for high gloss mirror finish, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

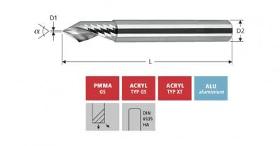

fine-grain solid carbide shape milling cutter: with 3-4 flutes, tapered, 0.5°-45°

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

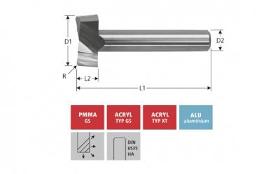

fine-grain solid carbide face milling cutter: with double flute, for high gloss mirror finish

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide deburring cutter: with four flutes

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide front-back deburring cutter 90°: with four flutes

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

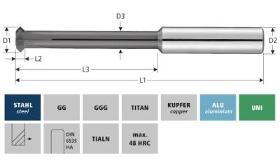

MCD circumference-milling cutter: with single flute, right-hand cutting, circumference-milling, end cutting, for high gloss mirror finish, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide engraving cutter: with single flute, upcut spiral, 30°/60°/90°

Request for a quote

SMG SPORTPLATZMASCHINENBAU GMBH

Germany

Art.-No. 3203710

Request for a quoteResults for

Cutters - Import exportNumber of results

24 ProductsCompany type