- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- connecting elements

Results for

Connecting elements - Import export

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our duct systems can feature flexible sections, smooth sections and tailored connections to meet customers specifications. This is a reliable way to connect a corrugated tube to the connecting cuff and allows for time-saving assembly. The advantages are obvious: Weight can be reduced, and great flexibility and high strength in the cuff section are guaranteed Available materials / maximum operating temperature: PA12 120°C PA6.10 120°C PA6.12 140°C PPA 180°C

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our corrugated tubes and smooth tubes with connecting elements are made to customers specifications for use in low pressure duct systems. This guarantees a reliable connection and an easy and time-saving assembly and disassembly. Our product line includes a wide range of nominal sizes and line of matched accessories. Available materials/maximum operating temperature: PP/PA 110°C PA6 120°C PA12 120°C Application: Automotive, agricultural machinery and construction engines; in applications that require a small bend radius and/or dynamic stress environments, ventilation systems, connecting lines between various components for vacuum conveying systems

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our duct systems for battery ventilation feature highly flexible sections combined with high stiffness in the cuff section. Connecting elements and matched accessories allow for easy assembly and disassembly. Available materials/maximum operating temperature: PP 100°C PA6 120°C PA12 120 Our corrugated tubes with integrated connecting geometries (bayonet lock) are made to customers specifications to guarantee reliable connections and to ventilate or drain duct systems. This saves weight and reduces the risk of leakage. The snap-in geometry allows for time-saving and user-friendly assembly and disassembly. Of course we offer a wide range of accessories and nominal sizes. Available materials/maximum operating temperature: PP 100°C PA6 100°C PA12 120°C

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our corrugated tubes with integrated valves to reliably vent or drain duct systems. The advantages are obvious: Weight can be saved, the risk of leakage can be reduced and assembly times can be shortened. The inside diameter and the volume are designed according to the flow rate, and the opening and closing characteristics of the valve are designed according to the pressure range. Available materials/maximum operating temperature: PP 100°C PA6 120°C PA12 120°C Application automotive, agriculture and construction engines; for ventilation applications for air filters or fuel systems Our corrugated tubes with integrated connecting geometries (bayonet lock) are made to customers specifications to guarantee reliable connections and to ventilate or drain duct systems. This saves weight and reduces the risk of leakage. The snap-in geometry allows for time-saving and user-friendly assembly and disassembly. Of course we offer a wide range of accessories and nominal sizes.

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our corrugated cable protection tubing for abrasion protection provides both superior flexibility and high mechanical strength. It allows easy insertion of cables and provides reliable protection of cables in high-vibration environments. The great advantage over smooth tubing is that connectors can be perfectly secured. Our product range also includes a wide range of matching accessories.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Flameproof immersion heaters ATEX II 2 G/D EEx d IIC IECEx Exd IIC T1 – T6 Ex tD A21 IP66 T…°C The EXHEAT “FP-C” range of flameproof core immersion heaters offers a hazardous area heating solution for oil and similar applications where a low heat density is required. The special element / sheath arrangement allows the element cores to be withdrawn for inspection without system drain down. The standard heater consists of a number of element cores fitted into a mounting flange. A robust EEx d terminal cover protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

EEx’e‘ certified immersion heater EEx e T1 – T6 ATEX The “FHK-Exe” type electric immersion heaters are EExe certified. These heaters are custom built to meet client specifications and suitable for use in zone 1 & 2 hazardous areas. The range of immersion heaters type FHK-Exe offers an economic heating solution for process tanks, pressure vessels and similar plant. The standard heater consists of a number of rod elements TIG welded into a process flange. A robust Ex’e’ terminal box protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

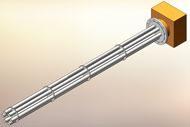

Immersion heater with cores The range of core immersion heaters type FHK-P offers a heating solution for liquid media where a low heat density is required. The special element / sheath arrangement allows the element cores to be withdrawn for inspection without system drain down. The standard heater consists of a number of core elements fitted into a process flange. A robust terminal box protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electrical flange type immersion heaters The range of immersion heaters type FHK offers an economic heating solution for process tanks, pressure vessels and similar plant. The standard heater consists of a number of rod elements TIG welded into a process flange. A robust terminal box protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Core Immersion heater ATEX II 2 G/D EEx d IIC T1 – T6 ATEX IECEx zertifiziert The EXHEAT® ‘FP-C’ Range of flameproof core immersion heaters offers a Hazardous Area heating solution for oil and similar applications where a low heat density is required. The special element/sheath arrangement allows the element cores to be withdrawn for inspection without system drain down. The standard heater consists of a number of element cores fitted into a mounting flange. A robust flameproof terminal enclosure protects the electrical connections. The number of element cores fitted depends upon the media to be heated and the kilowatt rating required.

Request for a quote

BDSENSORS GMBH

Germany

The DCT 531P was designed for use in the food / beverage and pharmaceutical industry. The compact design with hygienic versions guarantees an outstanding performance in terms of accuracy, thermal behaviour and long term stability. The integrated RS485 interface is characterized by a robust and reliable data transmission that works failure-free even over long distances. Additionally, the modular construction concept of the device allows to combine different electrical and mechanical connections. Features: — nominal pressure: 0 ... 100 mbar up to 0 ... 400 bar — accuracy: 0.25% FSO — output signal: RS485 with Modbus RTU protocol — CIP / SIP cleaning up to 150 °C — diaphragm with low surface roughness — reset function — ingress protection IP 67 / IP 69 Optional Features: — different process connections — cooling element for media temperatures up to 300 °C

Request for a quote

BDSENSORS GMBH

Germany

The pressure transmitter DMP 331P was designed for use in the food and pharmaceutical industry. The compact design with hygienic process connections makes it possible to achieve an outstanding performance in terms of accuracy, temperature behavior and long term stability. The modular construction concept allows a combination of various process connections with different filling fluids and a cooling element. Several electrical connections complete the profile of DMP 331P. Features: — nominal pressure: 0 ... 100 mbar up to 0 ... 40 bar — accuracy:0.35 % (opt. 0.25 %) FSO — hygenic version — diaphragm with low surface roughness — CIP / SIP cleaning up to 150 °C — vacuum resistant Optional Features: — IS-Version Ex ia = intrinsically safe for gases and dusts — SIL 2 according to IEC 61508 / IEC 61511 — cooling element for media temperatures up to 300 °C — diaphragm in Hastelloy® or Tantalum

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

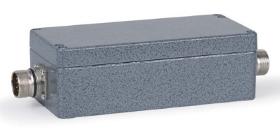

Interface electronics from HEIDENHAIN adapt the encoder signals to the interface of the subsequent electronics. They are used when the subsequent electronics cannot directly process the output signals from HEIDENHAIN encoders, or if additional interpolation of the signals is necessary. HEIDENHAIN interface electronics are available in various mechanical designs. Box design Because of their high IP 65 degree of protection, interface electronics with a box design are well suited for a rough industrial environment, for example where machine tools operate. The inputs and outputs are equipped with robust M23 and M12 connecting elements. The stable cast-metal housing offers protection against physical damage as well as against electrical interference. The EXE/IBV 100 series distinguishes itself from the EXE/IBV 600 series primarily in its compact dimensions.

Request for a quoteResults for

Connecting elements - Import exportNumber of results

14 ProductsCompany type