- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamp

Results for

Clamp - Import export

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Fränkische Industrial Pipes perceives itself as an international partner for developing technical sophisticated corrugated tubes, tubing systems and cable protection tubes as well as fluid systems for the automotive sector, household appliances, machine engineering and apparatus engineering and also for the industrial sector. The range of accessories is tailored to the most diverse applications of our corrugated tubes and protective sleeves

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatic control valve with angle seat design. The integrated positioner type 8049 means that a compact design is achieved. All parts that come into contact with the medium are made from stainless steel. Whitworth pipe thread NPT thread Welding ends Triclamp connection Special connections Digital positioner type 8049 Pneumatic and electropneumatic positioner type 8047 Positioner with integrated process controller type 8049 IPC Positioner type 8047 and type 8049 also in explosionproof version Piston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuator Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Highquality angle seat manual valve made from stainless steel, also suitable for neutral and aggressive media. The angle seat design offers a high flow rate.Whitworth pipe thread NPT thread Welding ends Triclamp connection Special connections

Request for a quote

MICRO-EPSILON

Germany

The LVP-25-Z20 and LDR-14-Z20 sensors are used for monitoring the clamping position in machine tools. These inductive sensors are integrated in the release device and directly measure the clamping stroke of the drawbar onto which the target ring is glued. Due to their extremely compact design, these sensors are used for different types of tools while providing high-precision and continuous monitoring. No adjustment is necessary when changing the tool.

Request for a quote

KAUP GMBH & CO KG

Germany

With the new view-optimised designed KAUP Rotating Roll Clamp T458B-2 roles and pipes can be taken up and transported carefully. The contact pad of this attachment is divided and allows in such a way that at the same time two roles - also with different diameters - can be transported stacked. This makes this attachment everywhere inalienable where the dandling of paper rolls, concrete tubes and similar is essential.

Request for a quote

KAUP GMBH & CO KG

Germany

With the new view-optimised designed KAUP Rotating Roll Clamp T458B roles and pipes can be taken up and transported carefully. This makes this attachment indispensable wherever you are dealing with the handling of paper rolls, concrete pipes and other similar items.

Request for a quote

KAUP GMBH & CO KG

Germany

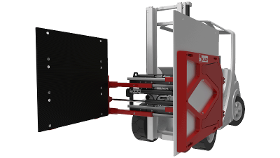

The combination with a rotary unit extends the application possibilities of the bale clamp of KAUP even more. Because with the Rotating Bale Clamp T453 the rotating and turning of goods without palettes like cellulose bale, material bale, paper bale, waste paper bale or tobacco bale become easily possible. The insides of the clamp arms of this attachment are optimised for the respective transport purpose. Generally the fixed arms are designed with toe-in.

Request for a quote

KAUP GMBH & CO KG

Germany

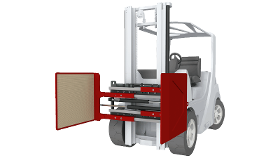

The KAUP Pallet Turnover Clamp T451W is an attachment designed with high visibility and suitable for all kinds of applications. It can be used to turn palletised and non-palletised goods or to exchange pallets e.g. from production pallets to transport pallets. It is also suitable for empting grid boxes or other transport containers.

Request for a quote

KAUP GMBH & CO KG

Germany

The KAUP Rotating Fork Clamp T451 is an attachment designed with high visibility. Its solid, strengthened construction using 1000-fold proven basic components of the KAUP modular system gives numerous possibilities for heavy duty applications.

Request for a quote

KAUP GMBH & CO KG

Germany

The extensive and many-sided drum clamp programme of KAUP encloses attachments which clamp, tip and turn single drums. Other attachments can carry up to four drums pre and side by side. The wide port folio is complemented by special solutions for the transport of special drums, by slip-on drum arms and drum tipping arms for already existing fork clamps.

Request for a quote

KAUP GMBH & CO KG

Germany

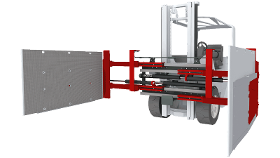

The KAUP Telescopic Appliance Clamp T413GT is used where white and brown product as well as other wide loading property is used. The slender clamp arms predestine this attachment for the truck and container loading.

Request for a quote

KAUP GMBH & CO KG

Germany

The KAUP Appliance Clamp T413G is used for the transport of white and brown product as well as other wide loading property. Equipped with very slender arms this attachment is suited particularly for the truck and container loading.

Request for a quote

KAUP GMBH & CO KG

Germany

KAUP Block & Brick Clamps are used worldwide for the non-palletised transportation of all kinds of industrially manufactured blocks and bricks. They grip packets of bricks from the side and are therefore suitable for handling of packets of upright format blocks with plane surfaces such hollow, lime sand and concrete blocks as well as curb stones. However the ideal Block and Brick Clamp can be configured to nearly every individual purpose. How? With the extensive KAUP Block and Brick Clamp program and the possibility to adapt KAUP attachments to suit nearly every individual working application.

Request for a quote

KAUP GMBH & CO KG

Germany

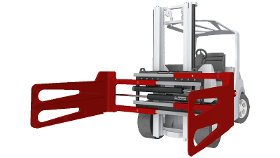

KAUP attachments of the class T413 designed with high visibility are mainly used for in-plant, non-palletised transportation of bales of paper, waste paper, tobacco and textiles or also boxes and containers. Pulp, foamed plastic (polystyrene) wool and Big-Bags can also be transported with specially designed clamping arms.

Request for a quote

KAUP GMBH & CO KG

Germany

The variously applicable Fork Clamp T411 is the base for all clamps of KAUP. Therefore, this attachment particularly suitable for hard use can be adapted very well to the individual demands. No matter, whether different hook-on fork cross sections for divergent charges, changed hook-on fork forms or the combination with other attachments: KAUP makes it possible.

Request for a quote

KAUP GMBH & CO KG

Germany

KAUP Appliance- and Carton Clamp T414B-1 are used world-wide for palletless transportation of white goods (fridges, washing machines etc.) and brown goods (electronic entertainment centres). For transportation of only one unit or up to 16 units: KAUP always has a suitable Appliance / Carton Clamp!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -For horizontal & vertical usage-suitable for CNC controlled milling machines & large machining centres -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely -Gripper studs suitable for materials with a strength of up toapprox. 1000N/mm² Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -Fully compatible with the accessories of the LC/TC 160 series, for example gripper studs, universal gripper set & pull down sets -Grounded sides so that all sides can be used High-pressure spindle with mech. force amplifier for the safe clamping of raw parts in combination with gripping & pull down spring function -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation -Suitable for conventional clamping and for gripper clamping or a combination of both -The support jaws enable a wide range of unmachined parts from flame-cut and sawn materials through to complex castings to be clamped securely and economically. Suitable for materials Product features: -Clamping range adjustment for clamping two workpieces of different sizes -Reproducible clamping forces enable excellent repeating accuracy of the workpiece position -Mechanical power-transfer device -Fully enclosed and maintenance-free high-pressure spindle – high chip protection, minimum cleaning requirements, constant clamping forces up to 40 kN -Use with a torque wrench – max. 40 Nm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Can be applied horizontally or vertically – therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, gripper clamping or pull-down clamping are all possible -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely and economically. Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested model -High-pressure spindle with power intensification. -Enlarged clamping span for secure clamping of unmachined parts -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER -Clamping near to neutral axes -Clamping jaws of forerunner are compatible -Clamping range of the middle fixed jaw groove: Max clamping width -176 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal and vertical installation – suitable for both vertical and horizontal CNC-controlled milling machines -Lateral installation is also possible Product features: -Extreme accuracy for your machining -The TC vice is ground and polished on all sides -Clamping force can be preset in 11 increments – fine gradations for delicate workpieces. At most, one revolution is required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm Important: -LC 200: jaw width 200 mm, width of vice base 164 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force - Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Conventional and CNC-controlled milling machines – for efficient precision machining -Horizontal installation – great variability and flexibility Product features : -Excellent ease of operation guarantees optimal handling in every situation -Fast adjustment for clamping range preselection -The clamping force is generated and preset via the hydraulic pressure of a hydraulic unit -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped -Coarse adjustment is performed by turning the spindle. The residual stroke of up to 4.5 mm is performed via a hydraulic unit with spring reset by means of a single-acting cylinder

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Conventional and CNC-controlled milling machines – for efficient precision machining -Horizontal installation – great variability and flexibility Product features : -Excellent ease of operation guarantees optimal handling in every situation -Fast adjustment for clamping range preselection -The clamping force is generated and preset via the hydraulic pressure of a hydraulic unit -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped -Coarse adjustment is performed by turning the spindle. The residual stroke of up to 4.5 mm is performed via a hydraulic unit with spring reset by means of a single-acting cylinder

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench Integrated scrapers ensure functional reliability and minimise cleaning Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quoteResults for

Clamp - Import exportNumber of results

52 ProductsCompany type